Product Features

● High quality alloy to prevent bursting

Imported ceramics + high-quality special alloys to ensure the consistency of the thermal expansion of the ceramic ring materials to prevent cracking.

● Stable signal, high sensitivity

Imported conductive silver gel and gold-plated copper needle, good conductivity, high sensitivity, good followability, effective insulation to reduce the sensor due to impact and damage.

● German technology, not deformed by heat

Ceramic body and alloy close fit, not deformed by heat surface finish is high, the air flow is more fluent.

● Pin position

After each ceramic environmental maintenance, need to reposition and test whether the light is in the center.

The role of ceramic ring in laser cutting mainly has the following aspects:

1. Protecting the cutting head: ceramic ring can effectively shield the laser cutting head from impact and contamination, prolonging its service life.

2. Reduce friction: ceramic ring has a small friction coefficient, which can reduce the friction between the cutting head and the workpiece and improve the cutting speed and quality.

3. Disperse heat: laser cutting process will generate a large amount of heat, ceramic ring can effectively disperse heat to prevent the cutting head from heat deformation and damage.

4. Multiple use: As the ceramic ring has high strength and wear resistance, it can be utilized many times to reduce the cost of use.

Advantages of Laser Cutting Ceramic Rings

1. High temperature resistance

The ceramic ring has excellent high temperature resistance, which can withstand the high temperature heat during the laser cutting process and ensure the stability of the cutting process.

2. High hardness

Ceramic ring has high hardness, which can effectively resist the wear and tear during the cutting process, prolong the service life and improve the cutting efficiency.

3. Good thermal conductivity

Ceramic ring has good thermal conductivity, can quickly dissipate heat, avoid localized overheating during the cutting process, and protect the surface quality of the workpiece.

4. Precision processing

The ceramic ring can be manufactured into various shapes and sizes through precision processing to meet different laser cutting needs and improve cutting accuracy.

5. Environmentally friendly and reliable

Ceramic rings are non-polluting and non-toxic, meeting the requirements of environmental protection, safe and reliable to use, and will not have a negative impact on the environment.

6. Cost-effective

Although the manufacturing cost of ceramic rings is high, the total cost is relatively low for long-term use due to its advantages of wear resistance and high temperature resistance, which has good cost-effectiveness.

When choosing ceramic rings, you need to pay attention to the following points:

1. Material hardness

When selecting a ceramic ring material, the primary consideration is its hardness. The higher the hardness of the ceramic ring, the better the abrasion and high temperature resistance, and better able to resist the high temperature and abrasion during the laser cutting process.

2. Thermal stability

The laser cutting process generates a lot of heat, so it is important to choose a ceramic ring with good thermal stability. Ensure that the ceramic ring will not be thermally deformed or thermally cracked in a high temperature environment.

3. Thermal conductivity

Good thermal conductivity can help the ceramic ring quickly dissipate heat to avoid overheating damage. Therefore, when selecting ceramic ring materials, focus on its thermal conductivity.

4. Chemical stability

Ceramic ring in the laser cutting process may come into contact with a variety of chemical substances, so good chemical stability is an important consideration in the selection of ceramic ring.

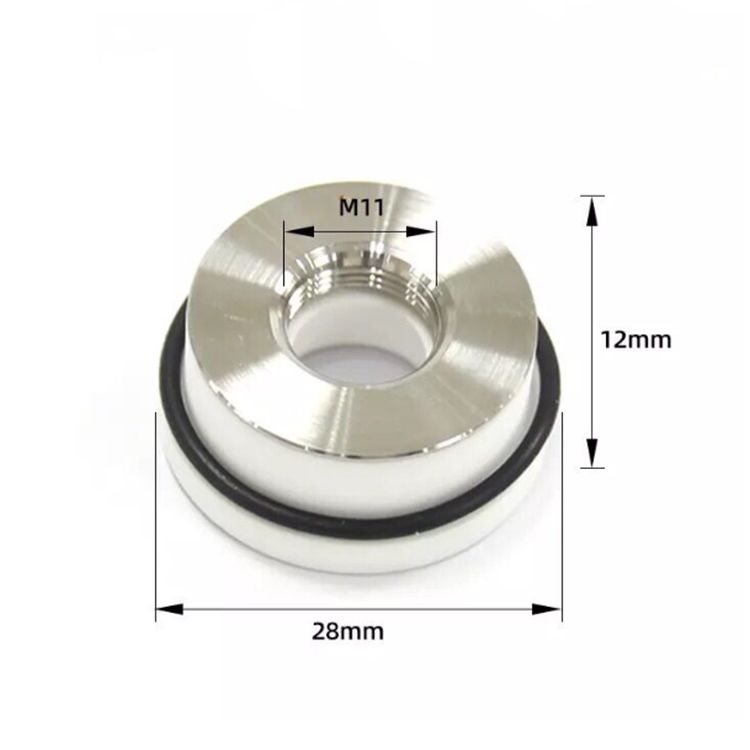

5. Dimensional accuracy

The dimensional accuracy of the ceramic ring directly affects the precision and stability of laser cutting. Selecting ceramic rings with high dimensional accuracy can improve cutting quality.

6. Cost Considerations

Finally, the cost of the ceramic ring should also be considered. Under the premise of quality assurance, the choice of cost-effective ceramic ring materials can effectively control production costs.

Maintenance and care of ceramic ring

1. Cleaning the surface of ceramic ring: When cleaning the surface of ceramic ring, you should use soft bristle brush and neutral cleaner to avoid scratching the surface.

2. Properly adjust the position of the ceramic ring: the ceramic ring should be as close as possible to the cutting head and keep the vertical angle between the plane and the cutting surface to ensure cutting quality and efficiency.

3. Avoid collision and vibration: Ceramic ring should be avoided from collision and vibration in the process of using. If there are cracks and breakage, etc., they should be replaced in time.