Product Parameters Samples Video

Features of laser cut aluminum

1. Fine cutting seam: The cutting seam of laser cutting aluminum plate is generally 0.1mm-0.2mm.

2. The cutting surface is smooth: the cutting surface of the laser cutting aluminum plate has no burrs and dross.

3. Small thermal deformation: Laser processing has thin laser slits, fast speed, and concentrated energy, so the heat transferred to the cut material is small, and the deformation of the material is also very small.

4. Saving materials: Laser processing adopts computer programming, and laser equipment can cut aluminum plate processing parts of different shapes, improve the material utilization rate of aluminum plates, and save a lot of material costs.

5. High photoelectric conversion efficiency: the conversion efficiency is over 30%, which can greatly save power consumption during work, save operating costs, and achieve the highest production efficiency.

Advantages of laser cut aluminum

● The auto-focusing laser head does not need manual focusing, which is easy to operate. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates, and automatically cut materials of different thicknesses.

● The bed adopts integral welding structure, rough machining after annealing to eliminate internal stress, and finishing machining with secondary vibration aging treatment, which greatly improves the stability of the machine tool.

● The gantry beam design is adopted, with light weight, good rigidity, good dynamic performance and stable operation. The fully enclosed dust-proof structure greatly improves the service life of the built-in rack and pinion and linear guide. Anti-corrosion, anti-oxidation, good toughness, good flexibility.

● High speed exchange worktable with high efficiency. The synchronous exchange worktable with patented technology can be exchanged in 7 seconds, and the machine automatically returns to the original position while the worktable is exchanged, so it is not necessary to adjust the accuracy after exchange, which is convenient for customers to load and unload and can improve the working efficiency.

● Adopt well-known brand Raycus, MAX, IPG and other fiber lasers. The beam quality is better and more stable, the anti-high reflection ability is stronger, the reliability is strong, and the service life is long.

Precautions for laser cutting aluminum

1. Need to pay attention to the laser speed when cutting aluminum, aluminum itself is not resistant to high temperature, once the cutting dwell time is not appropriate will produce burrs. Through the cutting focus, speed, output power, air pressure and other parameters of the adjustment, you can better cut aluminum.

2. Select the appropriate auxiliary gas, because of the special color of aluminum and to protect the uniform color of the cut products, nitrogen can well prevent oxidation and retain the characteristics of the material itself, the use of nitrogen is a better choice.

3. Use special anti-reflective material cutting head, which can effectively reduce the reflection damage to the lens.

Cutting capacity of fiber laser cutting machine metal (only for reference)

Power | Carbon steel (mm) | Stainless steel (mm) | Aluminum (mm) | Brass (mm) |

| Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness |

2KW | 16 | 10 | 8 | 6 | 6 | 4 | 6 | 4 |

3KW | 22 | 12 | 11 | 8 | 8 | 6 | 8 | 6(4) |

4KW | 25 | 14 | 12 | 10 | 10 | 8 | 10 | 8(5) |

6KW | 25 | 16 | 20 | 14 | 16 | 10 | 12 | 10 |

8KW | 40 | 20 | 30 | 18 | 30 | 16 | 16 | 12 |

12KW | 40 | 22 | 40 | 25 | 40 | 20 | 16 | 16 |

15KW | 60 | 25 | 50 | 30 | 50 | 25 | 20 | 18 |

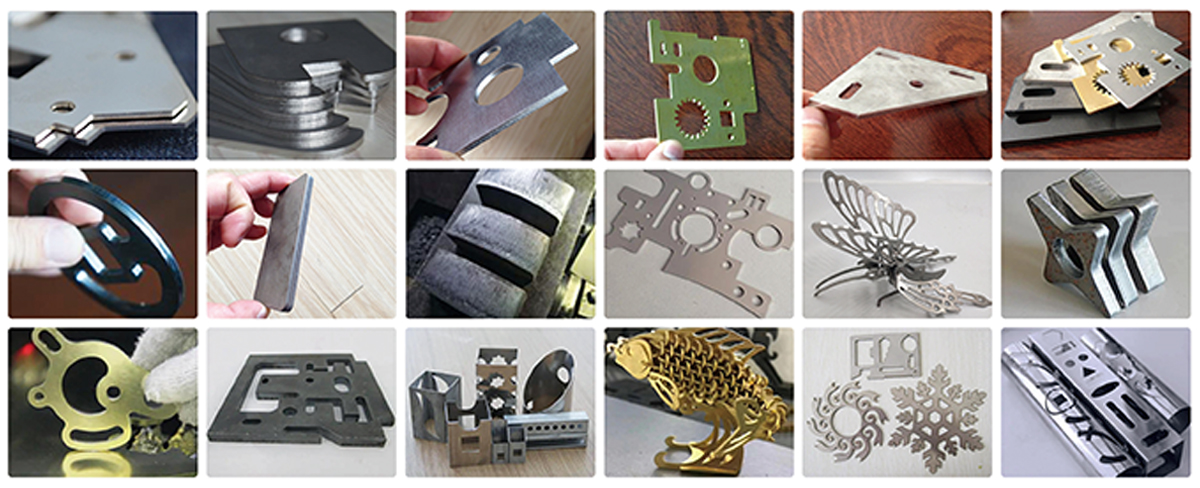

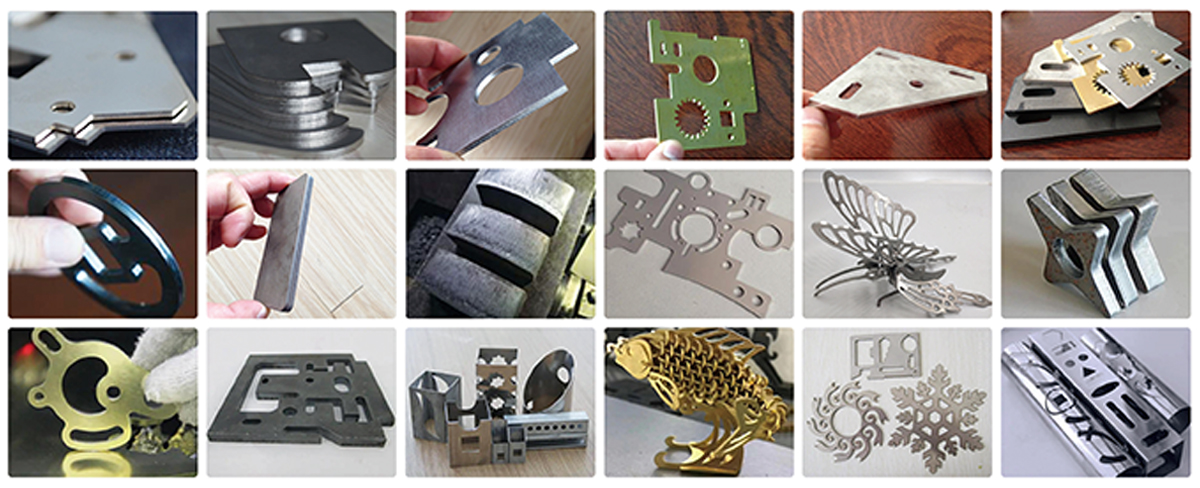

Laser cut aluminum application

Application materials

Suitable for aluminum, aluminum alloy, stainless steel, carbon steel, alloy steel, titanium alloy, galvanized sheet, brass, red copper, silver, gold, titanium and other metal materials.

Application industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, Various manufacturing and processing industries such as kitchenware processing.

Parameters of laser cut aluminum

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |