Product Parameters Samples Video

Features of high power laser cutting head

• Optional height sensor

• -10 mm~ +10mm focal length adjustment range

• The protective lens is equipped with real-time temperature monitoring to reduce the probability of lens overheating

• Adopts drawer-type mirror holder, making it easy and fast to replace the protective lens

• Flexible design to optimize spot size

• Portable and compact structure design

• Modular design can be adapted to various fiber optic interfaces

Application advantage of laser cutting head

(1) High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cutting surface without burrs.

(2) The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

(4) Good processing flexibility, can process arbitrary graphics, and can also cut pipes and other special-shaped materials.

(5) It can cut any hard material such as steel plate, stainless steel, aluminum alloy plate, and hard alloy without deformation.

Auto focus laser cutting head

◆ Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

◆ Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

◆ Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Advantages of laser cutting head machine tools

● We use a high-power machine tool with a hollow structure, which effectively reduces the heating area during the laser cutting process. The machine tool will not be deformed after long-term use, and it also ensures good cutting accuracy and greatly improves the stability of the machine. At least use 20 years will not deform.

● Our machine tools are welded with thick steel plates, and the weight of one machine tool alone reaches 4 tons.

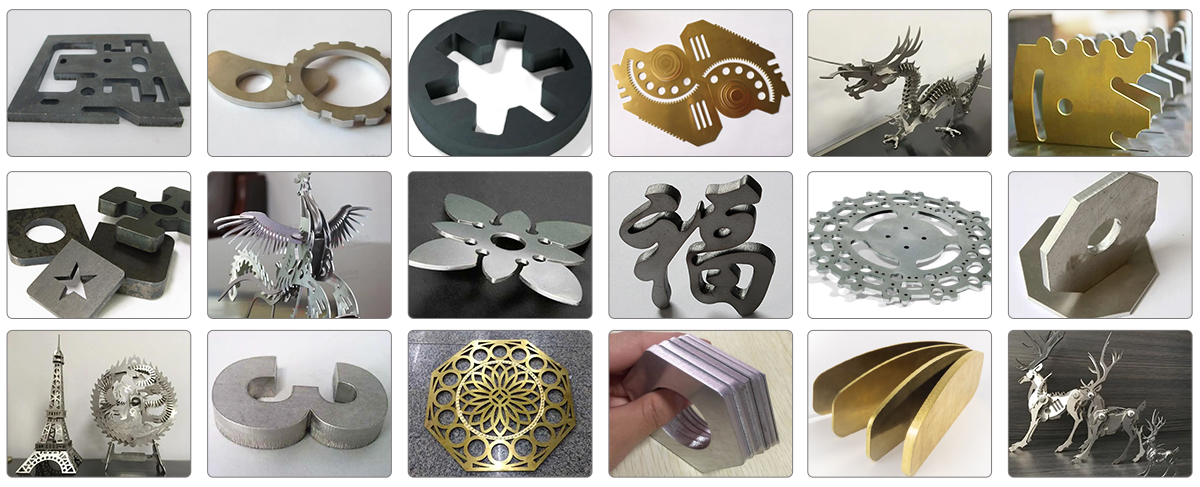

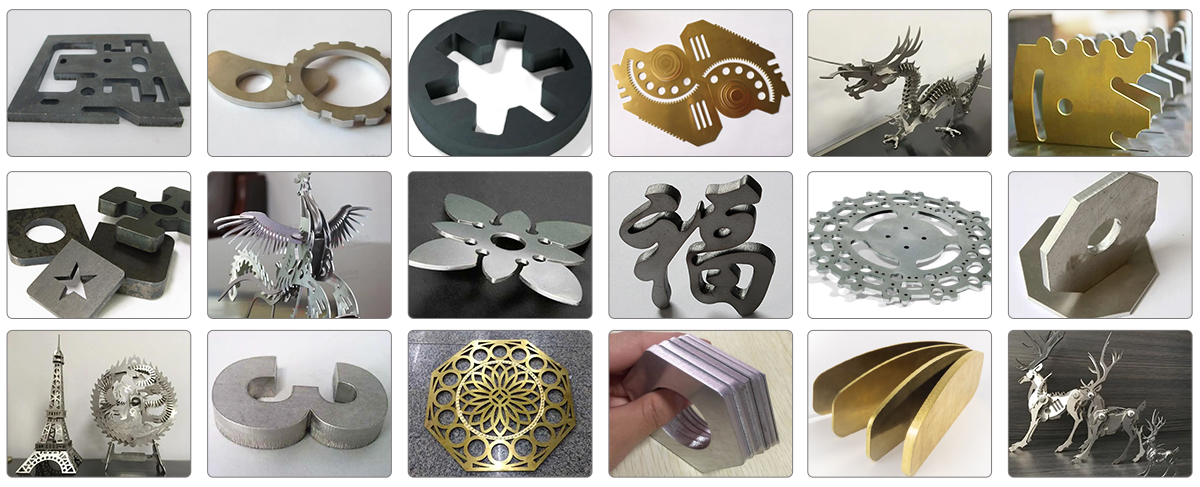

Laser cutting head application

Application materials

Suitable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal material.

Application industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, crafts and gifts, tool processing, decoration, advertising, metal external processing and other various manufacturing and processing industries.

Parameters of laser cutting head

Laser head |

Rated power | Up to 4KW |

Focal length | 100mm、125mm、150mm、200mm |

Clear aperture | 25mm |

Nozzle diameter | 0.5-3mm |

Nozzle Specifications | Single layer, composite, porous, shower type, customized |

Cutting pressure | ≤20Bar |

Focus range | -5mm-+8mm |

Weight | 1.5KG |

Collimator |

Collimation focal length | 60mm、75mm、100mm |

Clear aperture | 25mm |

Fiber optic interface | QBH、QD、LLK-B、PIPA-Q |

Height sensor |

Sensing distance range (recommended 1mm) | 0.2mm-8mm |

Calibration | Automatic calibration |

Reaction time | <1ms |

Temperature stability | 0°~45°,±5° |

Power requirements | 24V |

Output (linear curve or optimized curve) | 0~10V analog |