Details Product Parameters Samples Video

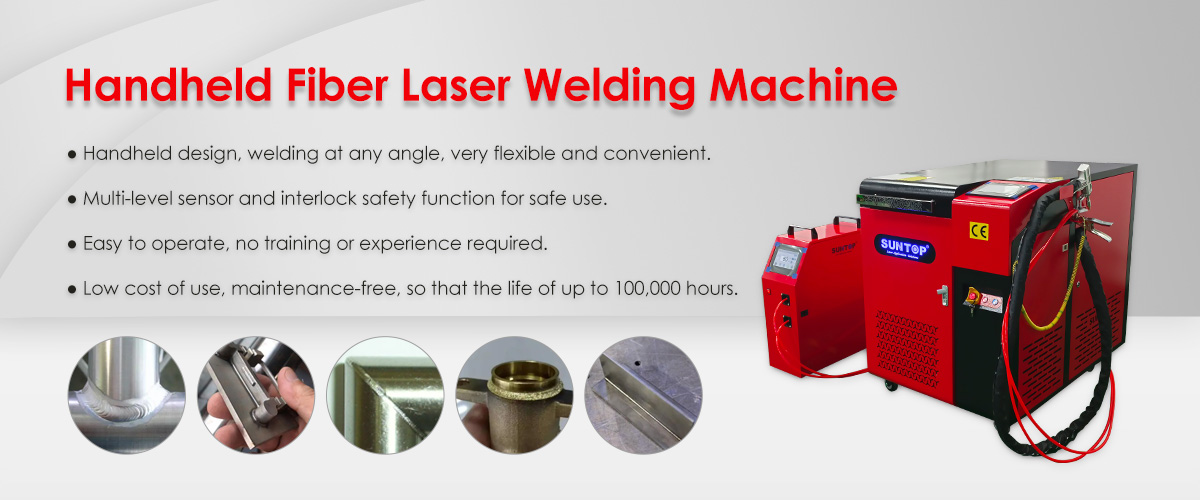

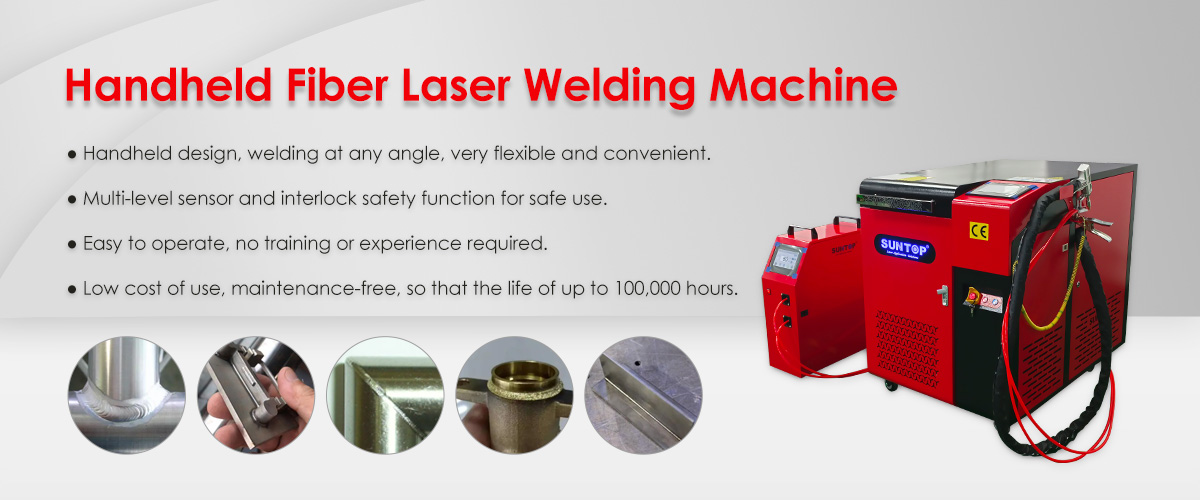

Features of handheld laser cleaner for sale

1. Adopting one-piece integrated structure design, integrating laser control system, laser and cooling integrated system in one cabinet, with reasonable structure, dustproof and good heat dissipation, which effectively extends the service life of machine parts.

2. self-developed Wobble welding head, small and lightweight, simple and flexible operation.

3. with automatic maintenance function, can automatically detect and repair equipment failure, reduce maintenance costs and downtime.

4. The machine has several safety alarm functions, the trigger switch is only effective when the welding nozzle touches the metal and the safety clip holds the metal plate, and the welding nozzle will automatically lock the light after removing the workpiece. The high safety of the machine guarantees absolute safety for the operator during work.

5. Suntop's patented technology water circulation protection system and auxiliary gas detection effectively extends the life of the laser lens and prevents damage to optical components caused by the laser lens. prevents damage to optical components caused by Improper operation. 6.

6. Adopts human-computer interactive interface, easy to operate. With automatic control function, it can realize automatic welding and reduce the complexity of manual operation. With real-time monitoring and alarm function, it can find and solve the problems in the welding process in time.

Details of handheld laser cleaner for sale

1. Laser cleaning head

Light weight only 0.8KG, flexible and convenient to weld any shape of metal parts, adjustable welding seam width, can carry out 10 meters long distance welding. Equipped with safety temperature monitoring system.

2. Operation interface

Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group welding parameter library, light output cumulative timing, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, supporting stainless steel and aluminum wire of 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter.

4. Laser Source

We use customized fiber with minimum core diameter of 20um for deeper penetration, laser life up to 100,000 hours, maintenance-free, with Bluetooth capability.

5. Water Cooler

Double circulation water cooling makes the laser source and weld head cooler, temperature control sensor adopts imported brand.

6. Welding connection fiber

10 meters long fiber optic cable built-in design, effectively avoid damage to the fiber and the problems caused by moisture, greatly improving the service life of the laser device.

Advantages of handheld laser cleaner for sale

1. One machine has multiple functions, equipped with a multi-purpose nozzle to meet the functions of welding, cutting, cleaning and so on.

2. The non-contact cleaning method does not damage the base material of the parts and avoids surface scratches and damage that may be caused by mechanical contact.

3. Parameters such as laser energy, scanning speed and focal length can be accurately adjusted to achieve precise control of cleaning depth and range, and adapt to the cleaning needs of various materials and surfaces.

4. There is no need to use any chemicals and cleaning fluids. The waste generated by cleaning is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, and pollution-free.

5. The machine has low cost of use and a service life of up to 100,000 hours. It is maintenance-free, installation-free and training-free. It is plug-and-play and is a very practical cleaning equipment.

6. There is no need for professional operators. Ordinary workers can get started in half an hour. They can carry it hand-held or cooperate with a robot to achieve automatic cleaning.

Cleaning ability (only for reference)

Power/W | Material | Cleaning speed | Effective beam/cleaning range | Depth of cleaning | Cleaning efficiency (cu.m./H) |

1500 | floating rust | 50mm/S | 150mm | 20um | 15 |

Paint | 50mm/S | 150mm | 100um | 6 |

Rusting | 50mm/S | 150mm | 120um | 4 |

2000 | floating rust | 50mm/S | 300mm | 20um | 20 |

Paint | 50mm/S | 300mm | 100um | 8 |

Rusting | 50mm/S | 300mm | 120um | 5 |

3000 | floating rust | 50mm/S | 300mm | 20um | 30 |

Paint | 50mm/S | 300mm | 100um | 14 |

Rusting | 50mm/S | 300mm | 120um | 9 |

Compared to traditional cleaning

Handheld laser cleaning:

√ The cleaning light source can adapt to the curved surface shape of the guide rail, minimizing damage to the substrate.

√ Laser cleaning can achieve selective removal of pollutants, improve cleanliness and protect substrates.

√ Green cleaning technology without consumables, eliminating dust pollution and greatly reducing cleaning costs.

√ The clean light source can be transmitted flexibly by optical fiber and integrated with the robot to improve work efficiency and reduce labor costs.

Traditional cleaning:

× Deep sanding destroys surface curvature and has a serious effect on substrate damage.

× Reduce the amount of grinding and ensure the shape of the curved surface, but it will cause serious rust residues and lay a huge safety hazard.

× It consumes a large amount of grinding wheel consumables, which is expensive, seriously pollutes the environment, and poses a serious hazard to workers' health.

× The work efficiency is low, the cleaning cycle is long, and the labor cost will inevitably increase.

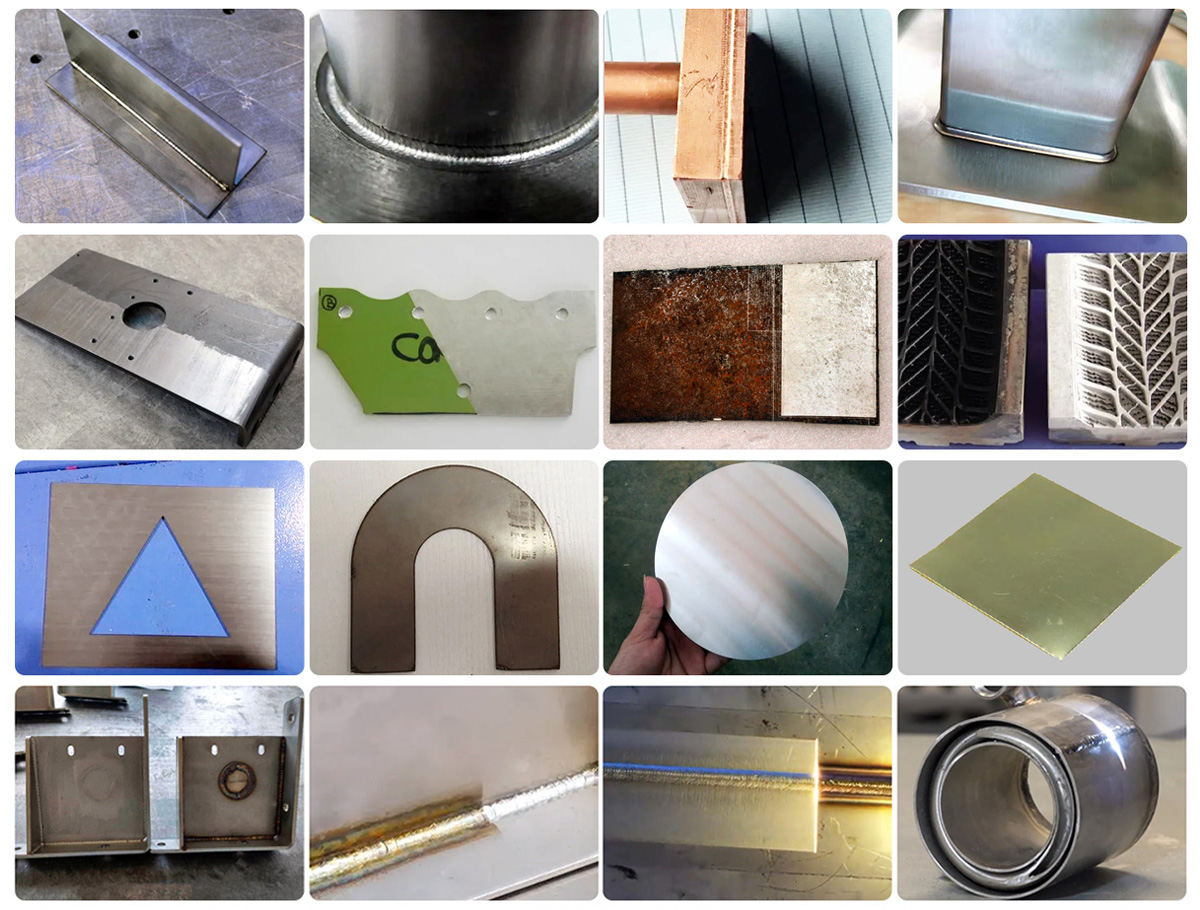

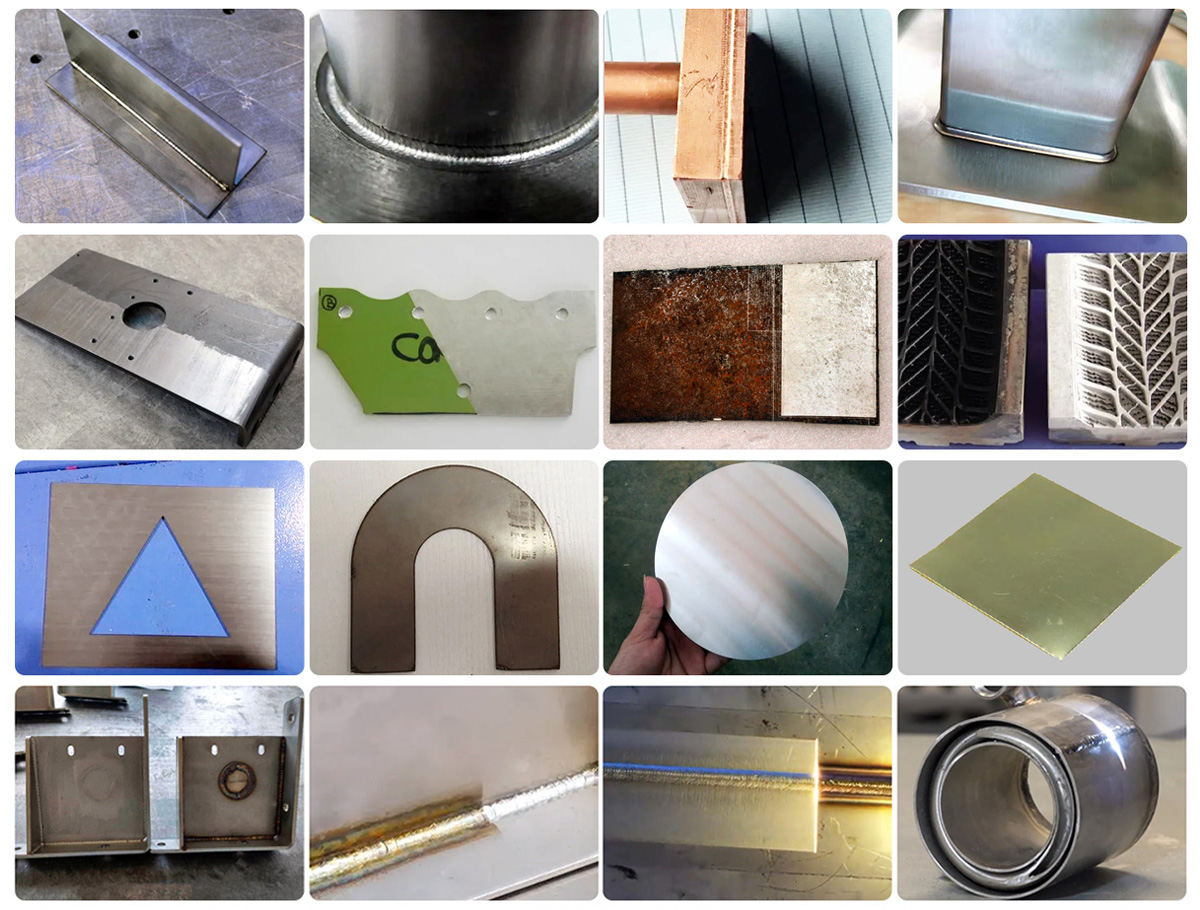

Application materials

Suitable for stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various weldings between different materials, such as copper-brass, titanium-molybdenum, titanium-gold, nickel-copper, etc.

Suitable for removing resin, paint, oil stains, stains, dirt, rust, coatings, etc. from the surface of objects.

Application industry

Used in automotive parts, shipbuilding industry, aerospace, 3C electronics, precision parts, molds, high-end machine tools, military equipment, hardware manufacturing, kitchen and bathroom, home appliances, motor accessories, bellows, batteries, solar energy, optical communication shells and other industries field.

Parameters of handheld laser cleaner for sale

Model | ST-FW1500H | ST-FW2000H | ST-FW300H |

Power | 1500W | 2000W | 3000W |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire)

| Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |