Details Product Parameters Samples Video

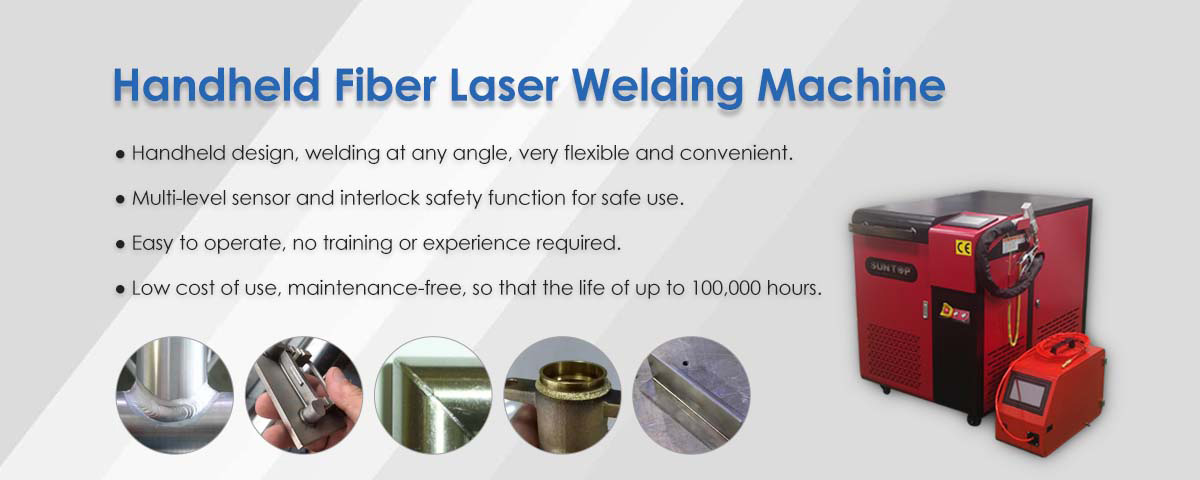

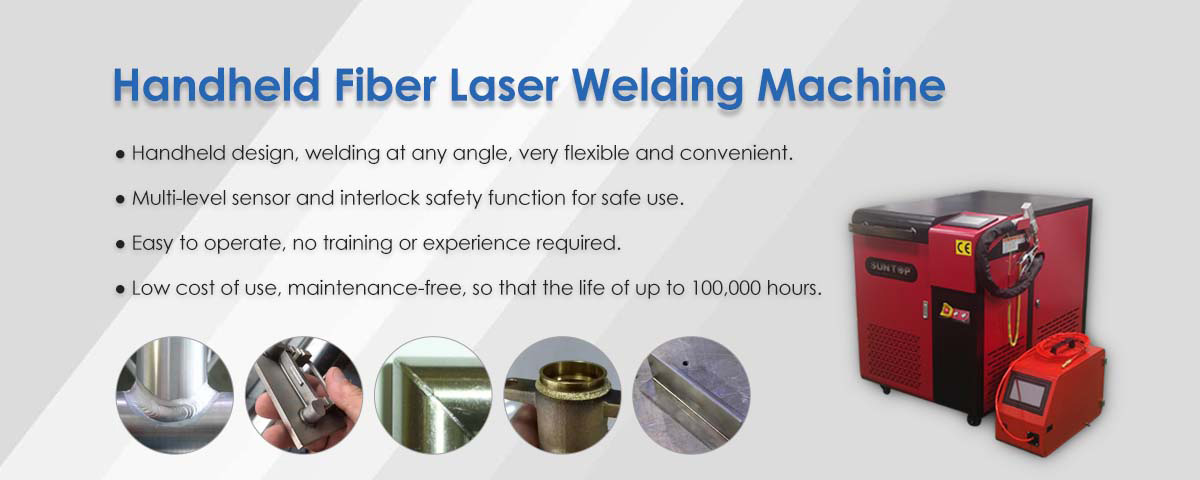

Features of portable laser welding machine

1. Use infrared positioning to verify the position of the welding head and verify the position during the welding process. The welding position is more accurate, the weld seam is smooth and beautiful, easy to grind and polish, and no post-welding treatment or only simple treatment is required.

2. Professional laser welding software, powerful and easy to learn and use, ordinary workers can start working after simple training, no need for professional welders.

3. The electrical control area is equipped with a cooling fan as standard, which can effectively improve the welding stability in high temperature environment.

4. Visual instrument and water injection port can be observed at any time during use. At the same time, the touch screen control panel is used to modify the process parameters, which is more intuitive and convenient

5. It has multiple safety alarm functions. The trigger switch is only effective when the welding copper nozzle touches the metal and the safety clip clamps the metal plate. After the welding copper nozzle removes the workpiece, it will automatically lock the light. The safety of the machine is high, ensuring the absolute safety of the operator during work.

6. Equipped with double protection function of water circuit and air circuit (patented technology), which effectively avoids the damage of laser lens or optical components caused by operator's misoperation, thus greatly reducing the failure rate of the machine and effectively prolonging the service life of the machine. The life of the consumables.

7. The system can store a variety of different process parameters, which can be switched at any time through the touch screen according to processing requirements, reducing the time for parameter debugging.

Details of portable laser welding machine

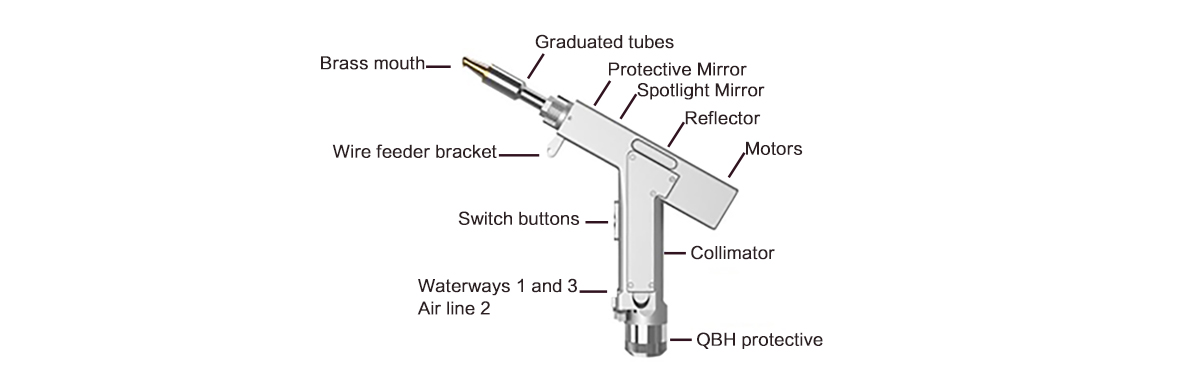

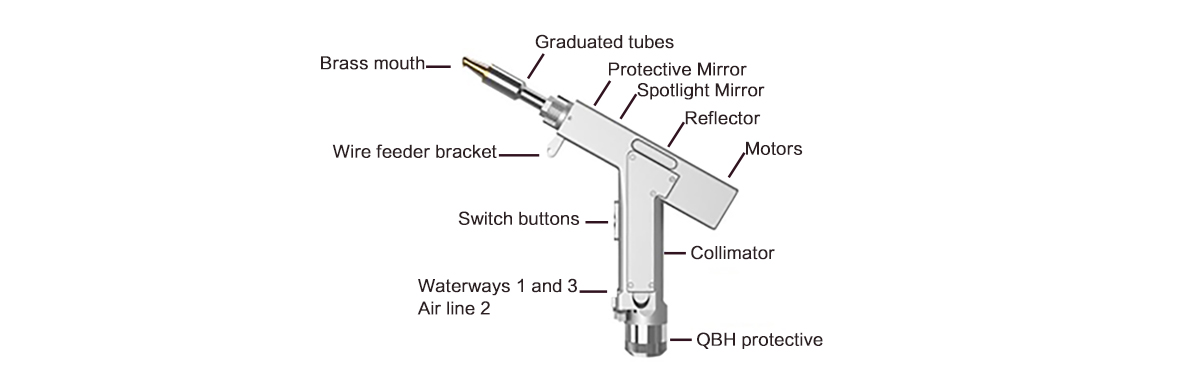

1. Laser welding head

Light weight only 0.8KG, flexible and convenient to weld any shape of metal parts, adjustable welding seam width, can be 10 meters long distance welding. Equipped with safety temperature monitoring system.

2. Operation interface

Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group welding parameter library, light output cumulative timing, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, support 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter stainless steel and aluminum wire.

4. Laser Source

We use customized minimum 20um core diameter fiber for deeper penetration, laser life up to 100,000 hours, maintenance-free, with Bluetooth capability.

5. Water Chiller

Double cycle water cooling makes the laser source and welding head cooling better, temperature control sensor adopts imported brand.

6. Welding connection fiber optic

10 meters long fiber optic cable with built-in design effectively avoids damage to the fiber and problems caused by moisture, which greatly increases the service life of the laser components.

Advantages of portable laser welding machine

1. Wide welding range: The handheld welding head is equipped with 10m original optical fiber, which can overcome the limitation of workbench space and can be used for outdoor welding and long-distance welding.

2. Easy to use and flexible: handheld laser welding is equipped with moving pulleys, comfortable grip, adjust the work position at any time, no need to fix the work position, free and flexible, suitable for a variety of work environment scenarios.

3. Multiple welding methods: It can realize welding at any angle, stack welding, butt welding, vertical welding, flat angle welding, inner angle welding, outer angle welding, etc. It can weld workpieces with various complex welds, larger workpieces with irregular shapes, and realize welding at any angle.

4. Good welding effect: laser welding has a higher energy density, can achieve better welding effect, welding area heat impact is small, not easy to deformation, blackening, back traces of the problem, welding depth, full melting, solid and reliable, the strength of the weld reaches or even exceeds the parent material itself, which can not be guaranteed by ordinary welding machine.

5. low maintenance costs: the laser life of up to 100,000 hours or more, the daily basic maintenance-free, save energy and more.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Brass/copper (mm) | 0.5-1.5 | 0.5-2 | 0.5-3 |

Galvanized sheet (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times

Worble laser head

● Hand-held oscillating welding mode, which can meet multi-angle and multi-position welding.

● Self-developed, set various safety alarms, easy and flexible operation.

● Visualization of all parameters, real-time monitoring of the whole machine status, avoiding problems in advance, facilitating troubleshooting and problem solving, ensuring stable system operation.

● All process parameters can be set, and it is flexible to test various process effects.

Automatic wire feeder

● Our wire feeder with touch capacitive screen, high precision wire feeder.

● 220V drive, more powerful wire feeding, no wire jamming.

Suntop wire feeder specifications |

Wire feeding type | Automatic (also support the manual mode) |

Length of wire feed tube | 3m/5m optional (9.8ft/16.4ft) |

Interface | Low voltage enable signal line |

Wire feeding speed range | 40-600 cm/min (15- 230 ipm) |

Compatible wire diameter | 0.8 mm (0.031 inch), 1.0 mm (0.039 inch), 1.2 mm (0.047 inch), 1.6 mm (0.063 inch), 1.8 mm (0.071 inch), 2.0 mm (0.079 inch) |

Wire reel capacity | 1 kg (2 lbs), 5 kg (10 lbs) or 10 kg (25 lbs) by shaft change |

Compatible wire materials | Steel, stainless steel, aluminum (common to conventional MIG and TIG wires) |

Power requirement | 220V 50/60Hz |

Wire feed unit weight | 22 kg (48.4 lb) |

Wire feeder unit dimensions (L*W*H) | 560mm (22.0 inches) x 250mm (9.8 inches) x 360mm (14.2 inches) |

Compared to traditional welding

● Handheld laser welding machine saves about 80%-90% of electrical energy, and processing cost can be reduced by about 30%.

● Handheld laser welding machine can be used for various welding between different materials.

● Fast speed, 5-10 times faster than traditional TIG welding, small deformation, small heat affected zone.

● The welding seam is beautiful, flat, no/less porosity and no pollution. Micro and small parts and precision welding can be performed.

● No or only simple treatment after welding (depending on the weld surface effect required), greatly reducing the labor cost consumed in the process.

| TIG or MIG Welding | Fiber laser welding |

Heat effect to workpiece | Very high | Low |

Deformation of the workpiece | Big | Small or No |

Bonding strength to base metal | General | Very good |

After-treatment | Polishing | No need to rarely to polish |

Welding speed | General | 5-10 traditional welding |

Consumables | More | Less |

Operation difficulty | Complex | Simple |

Operational safety | Unsafe | Safe |

Environmental pollution | High | Less |

Welding fault tolerance | Good | Good |

Swing welding | No | Yes |

Spot width adjustable | No | Yes |

Welding quality comparison | Different | Very good |

Portable laser welding machine application

Application materials

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Application industry

Widely used in sheet metal welding (stainless steel, carbon steel), sheet metal, molds, chassis, water tanks, kitchen and bathroom products, hardware accessories, billboards, door and window frames, household appliances, handicrafts, household items, auto parts and many other industries.

Parameters of portable laser welding machine

Model | ST-FW1500H | ST-FW2000H | ST-FW3000H |

Max. output laser power (W) | 1500 | 2000 | 3000 |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc.. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire) | Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |