Details Product Parameters Samples Video

Features of gold spot welding machine

·The energy, pulse width, frequency, and spot size can all be adjusted within a wide range to achieve various welding effects. The parameters are controlled by a control rod inside a closed cavity, making it simple and efficient.

·It adopts a ceramic focusing cavity imported from the UK, which is corrosion-resistant, high-temperature resistant, and has a high photoelectric conversion efficiency. The focusing cavity has a lifespan of 8-10 years, and the xenon lamp has a lifespan of over 8 million times.

·It uses an advanced automatic shading system, eliminating the stimulation of light to the eyes during work.

·It has the ability to work continuously for 24 hours, with stable overall performance and no maintenance required within 10,000 hours.

·It is designed with humanization in mind, conforming to ergonomics and allowing for long periods of work without fatigue.

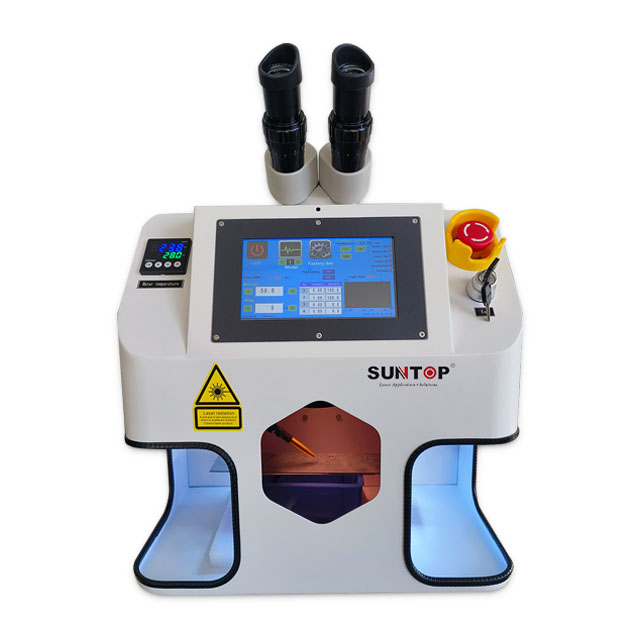

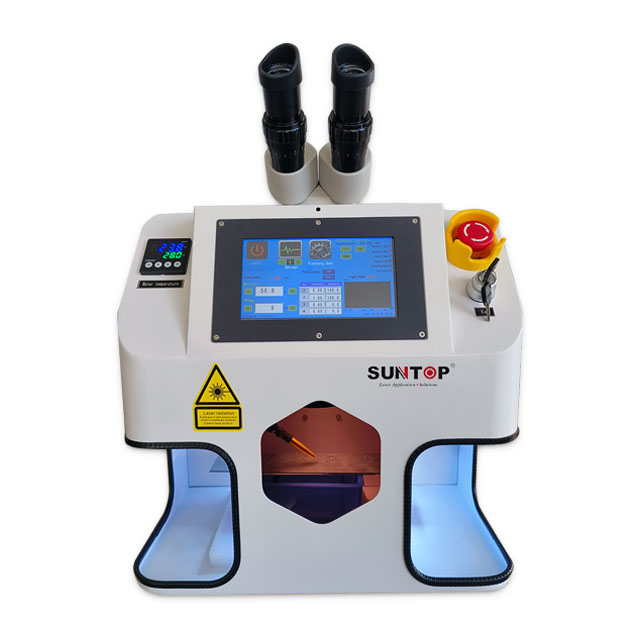

Details of gold spot welding machine

1. Humanized design

It adopts the latest European portable mini design, a scientific and streamlined mechanical structure, a high-grade alloy chassis, and is anti-static, anti-rust, easy to move, and space-saving.

2. Observation microscope

A top-quality high-precision microscope (10×/20 times) from China is used for precise positioning and the welding process.

3. Control screen

It has a built-in touch screen control system with high sensitivity and convenient parameter setting. Users can set different parameters (current, frequency, pulse...) according to different materials.

4. Laser optical path

The machine uses the Morgan brand optical cavity imported from the UK to protect the laser source and prolong its service life. It also adopts a durable crystal rod designed by China's 11th Academy of Sciences.

5. Laser xenon lamp

It adopts the original xenon lamp from a top Chinese brand. The lifespan of the lamp is 8 million times, and it can be used for 6-12 months when working 8 hours a day. When the xenon lamp is used up, it can be easily replaced with a new one.

6. Joystick

Users can adjust the position of the cursor and set parameters by moving the joystick while performing welding work. (emergency stop/joystick/brightness)

7. LED lights

Users can adjust the brightness of the LED light according to their comfort level.

8. Gas pipe

To ensure clean welding, it is necessary to blow argon to protect the welding surface.

9. Working table

The machine has a large internal working space and a flexible angle for ease of use.

10. Exhaust fan

There is an exhaust fan at the back of the machine to assist with cooling. Additionally, there is a water cooling system inside the machine.

Advantages of gold spot welding machine

1. High precision: Compared to traditional spot welding machines, jewelry laser spot welding machines have higher precision in welding positions, allowing for fine welding in small spaces, making the welded jewelry more aesthetically pleasing.

2. No additional welding materials required: By using melting welding technology, there is no need for additional welding materials, which can reduce the cost of jewelry production.

3. Minimal heat impact: By using a high-energy density power source, the welding point is instantly heated and melted, resulting in a short welding process time. This reduces the size and depth of the heat-affected zone on the metal surface, minimizing or eliminating material deformation and avoiding heat impact.

4. Small welding points, less prone to damage during processing: It has the advantage of small and precise weld seams. When the welding depth is sufficient, the gap is small, the speed is fast, and the heated area is small, making it less prone to deformation or damage. The frequency and size of the light spot need to be adjusted significantly to achieve various welding effects.

5. Fast welding speed: It can significantly improve work efficiency, is less prone to deformation, and requires no post-welding correction or polishing, eliminating the need for secondary processing.

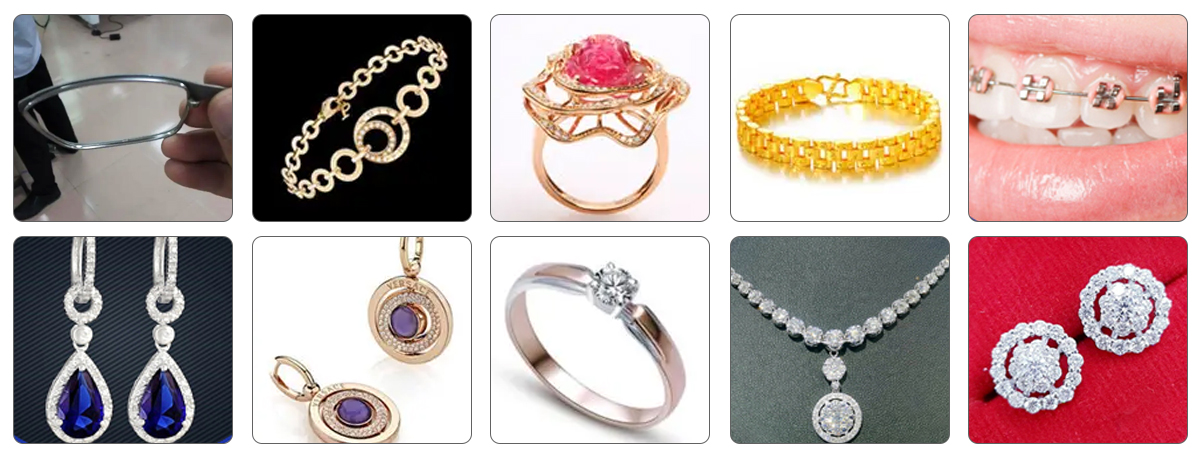

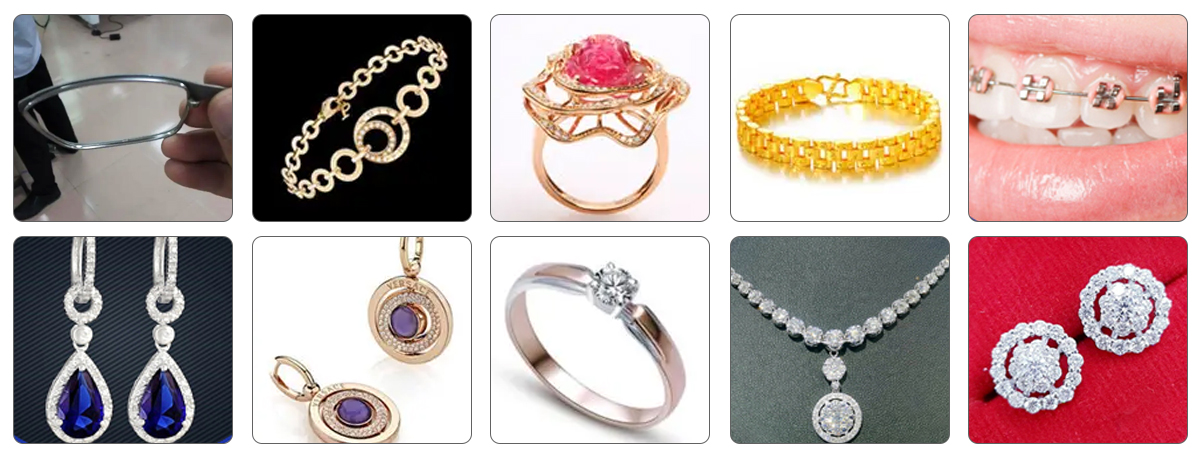

Application materials

Suitable for gold, silver, platinum, copper, titanium, stainless steel and other metal materials, rings, earrings, bracelets, necklaces, tie clips, cufflinks and other jewelry, metal jewelry welding.

Application industry

Widely used in aviation, aerospace, sporting goods, jewelry, golf head, medical equipment, aluminum alloy denture, instrumentation, electronics, machining, automotive and other industries, especially for gold and silver jewelry to fill the holes, spot weld seam lines, inlaid pieces of the force and claw foot parts of the welding.

Parameters of gold spot welding machine

Model | ST-WY150 |

Max. laser power | 150W |

Laser wavelength | 1064nm |

Total power consumption | 5KW |

Pulse energy | 50J |

Laser focus | 110mm |

Laser pulse repeatable frequency | ≤0.1-20Hz |

Observation system | Microscope 10X or CCD camera |

Cooling | Internal water cooled |

Water T.M Protection | 10-30 degree |

Laser pulse width | ≤20ms |

Laser protection gas | Argon |

Controls | Touch screen or joystick |

Power supply | AC220V±10%,50/60Hz |

Dimension | 900*500*600mm |