1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

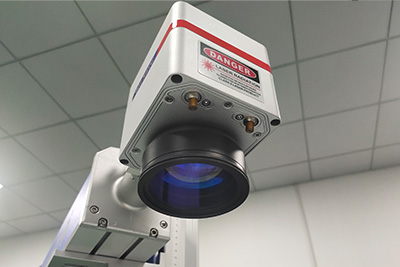

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. Can a 50W fiber laser cut metal?

Yes, a 50W fiber laser can cut some thinner metals, such as stainless steel and aluminum, but the thickness it can cut is limited. For thicker metals, it is generally recommended to use a higher-power laser cutter.

6. How fast does a 50W fiber laser cut?

The cutting speed depends on the type and thickness of the material and the laser parameters set (such as power, focus, etc.). Generally speaking, a 50W fiber laser cuts thin materials (such as thin stainless steel or aluminum) at a respectable speed, but it cuts thicker materials at a relatively slow speed.

7. Which accessories need to be replaced regularly when cutting with a 50W fiber laser?

In daily use, the maintenance cost of a fiber laser is relatively low, but it is still recommended to regularly check and clean the laser lens and focusing mirror to ensure the quality of the beam. Generally, fiber lasers have a long service life and do not need to be replaced frequently.

8. Is there any waste or smoke generated during the cutting process?

Yes, waste and smoke are generated during laser cutting. In order to ensure a clean and safe working environment, it is recommended to use a fume exhaust device or an exhaust system to deal with the smoke and steam generated during cutting.

9. What is the edge quality after cutting? Does it require post-processing?

The cutting edge of the 50W fiber laser marking machine is relatively smooth, but the specific quality depends on the material and parameter settings. In some cases, simple post-processing (such as deburring) may still be required, especially if there are high requirements for cutting quality.

10. How to improve cutting effect and efficiency?

The key to improving cutting effect and efficiency lies in the reasonable setting of parameters such as laser power, focusing distance, and cutting speed. Regular maintenance of the equipment is also the key to ensuring cutting effect. Users can conduct small-scale tests according to different materials and thicknesses to find the best parameter settings.

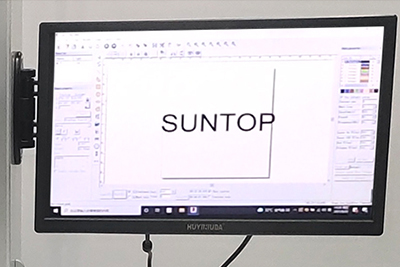

11. Does the cutting function of the 50W fiber laser marking machine require special software?

The fiber laser marking machine is equipped with easy-to-use software that can set the cutting path and laser parameters. These software usually support multiple file formats, such as DXF, PLT, etc., and can customize cutting and marking designs.