Metal laser engraving machines have become increasingly popular in the manufacturing industry in recent years, and their advantages are reflected in many aspects compared to traditional processing methods. The following is a detailed introduction to the advantages of metal laser engraving machines:

1. High-precision processing

Metal laser engraving machines can achieve extremely high processing accuracy, and the diameter of the laser beam can reach tens of microns, making the engraving results very delicate. Such high precision can meet the processing requirements of complex patterns, texts and logos, and is particularly suitable for the customization of high-end products.

2. Fast processing speed

The processing speed of laser engraving machines is much higher than that of traditional mechanical engraving methods. In mass production, the processing efficiency is significantly improved, which can significantly shorten the production cycle. Therefore, for orders that need to be delivered quickly, metal laser engraving machines are a more efficient choice.

3. Low operating cost

The laser equipment has low energy consumption, and the laser source has a long service life. The cost required during maintenance and operation is also relatively low. In the long run, it can obtain a higher return on investment.

4. Flexibility and customizability

Metal laser engraving machines can process a variety of metal materials, including stainless steel, aluminum, copper and alloys, and have extremely high compatibility. In addition, users can edit and modify design content in real time through computer software, and support multiple file formats, making the production process more flexible and able to adapt to diverse market needs.

5. Save materials

Laser engraving is a non-contact processing method that can effectively reduce material waste. Due to the precise positioning and cutting of the laser beam, the utilization rate of materials is improved, which reduces production costs while also reducing waste and resource consumption, in line with the sustainable development concept of modern manufacturing.

6. No mold required

Traditional engraving methods often require mold making, while metal laser engraving machines do not require molds, reducing mold making time and cost. This feature is particularly suitable for small batch production or personalized customization needs, and can respond quickly to market changes.

7. Environmental protection characteristics

The processing process of metal laser engraving machines usually produces very little waste and pollutants. Compared with traditional processing methods, laser engraving does not require the use of a large amount of chemical cleaning agents, reducing the impact on the environment and meeting modern environmental protection requirements.

8. Stability and reliability

Metal laser engraving machines are usually composed of high-quality components and have strong stability and reliability. Many high-end equipment can run continuously for a long time, which reduces the failure rate and requires relatively less maintenance, increasing the service life of the equipment.

9. User-friendly operation

The easy-to-use interface and operating software allow users to quickly get started even without much expertise. In addition, the high degree of automation of the equipment can reduce dependence on manual labor and improve overall work efficiency.

10. Wide range of applications

Metal laser engraving machines have a wide range of applications in multiple industries, including but not limited to electronics, automobile manufacturing, pharmaceuticals, aerospace, jewelry, advertising logos, etc. The diversity of its applications makes the equipment have a rich demand in the market.

Metal laser engraving machines have become an important processing tool in many industries due to their high precision, high efficiency, low cost of use and environmental protection. Click here to contact Suntop Laser now to get free laser engraving tests on various materials.

Laser Power | 20W | 30W | 50W | 60W | 70W | 100W |

Model | ST-FL20P | ST-FL30P | ST-FL50P | ST-FL60P | ST-FL70P | ST-FL100P |

Max Marking Range | 110*110mm /150*150mm | 200*200mm | 300*300mm | 450*450mm | 450*450mm | 450*450mm |

Depth of Single Marking | 0.01mm | 0.03mm | 0.06mm | 0.07mm | 0.07mm | 0.1mm |

Same pattern marking efficiency | 10s | 7s | 4s | 3s | 3s | 2s |

Whole Machine Power | 600W/h |

Laser Type | Fiber Laser |

Laser Source | MAX Brand (Raycus can choose) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Working Accuracy | ±0.002MM |

Marking Speed | 0-7000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 1064nm |

Minimum Font for Marking | 0.15mm |

Working Voltage | 220V±10%, 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC, PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 48KG |

Machine Dimension | 420*300*550mm (L*W*H) |

Which Materials Can be Laser Engraving? Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc., and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.

What Are Metal Laser Engraving Used For?

Metal fiber laser engraving machines are widely used in many industries and fields due to their high precision, high efficiency and wide range of applications. The following are the main applications of metal fiber laser engraving machines:

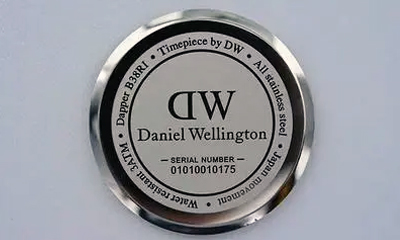

Metal logo and nameplate production

Widely used to make metal logos, nameplates and labels, suitable for the identification of enterprises, industrial equipment, tools, machinery, etc.

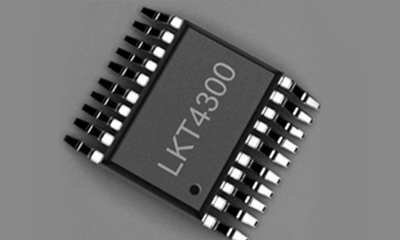

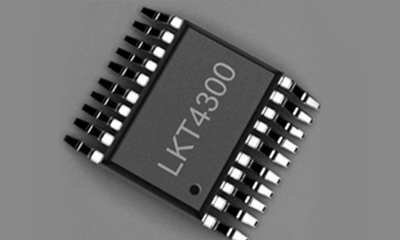

Electronics industry

Used for etching and marking electronic components, such as engraving numbers on circuit boards, company logos and other important information.

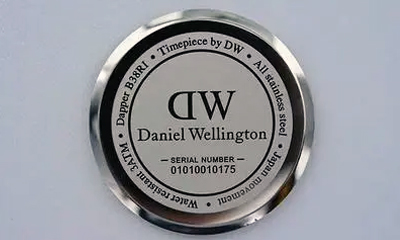

Jewelry industry

Used in jewelry processing to engrave detailed patterns, texts and personalized designs on metal jewelry to enhance the added value of products.

Automobile industry

Applied to the marking and decoration of automobile parts, body nameplates, engine covers, local detail processing, etc.

Aerospace

Used for precision engraving of aircraft parts and instruments to ensure clear visibility of logos or serial numbers and meet strict quality standards.

Medical industry

Laser engraving on medical devices and equipment to quickly mark important information, such as product numbers, instructions for use or warning signs.

Machinery manufacturing

Used for etching machine parts and detailed engraving when manufacturing precision tools and molds.

Advertising and art

Engrave and cut on billboards, artworks, and personalized gifts to meet the personalized needs of customers.

Home decoration

Use engraving technology to design on metal home decorations to add unique style, such as metal wall decorations, countertops, etc.

Anti-counterfeiting and traceability system

Engrave anti-counterfeiting logos, QR codes, barcodes, etc. on products to enhance product security and traceability.

Scientific research and laboratories

Perform fine engraving and personalized marking on scientific research equipment to meet the needs of experiments, records and research.

Mechanical equipment and equipment

Engrave on various tools and machinery to indicate usage information, brand logos and specifications.

With the continuous advancement of technology and the continuous expansion of the application of laser engraving technology, the application scenarios of metal fiber laser engraving machines may be richer and can meet the needs of more industries.Click here to contact Suntop Laser now for more information on laser engraving machines.

Metal Laser Engraving Machine Video How to Choose the Metal Laser Engraving Machine for You?

Choosing the right metal laser engraver for you is an important decision that involves multiple factors. Here are some key considerations and steps to help you make the right choice:

1. Identify your application needs

Engraving material:Determine the type of metal you need to engrave (such as stainless steel, aluminum, brass, etc.) and its thickness.

Engraving accuracy:High-precision engraving machines are suitable for projects that require detailed work.

Engraving speed: Choose the appropriate engraving speed according to production needs to ensure that it is compatible with production efficiency.

Engraving depth: If deep engraving is required, please confirm the maximum engraving depth of the model.

2. Laser type

Fiber laser: Suitable for metal engraving, with high efficiency and excellent beam quality, suitable for a variety of metal materials.

CO2 laser: Although mainly used for non-metallic materials, it can also effectively engrave some special metal materials and coatings.

3. Power selection

Choose a laser power that suits your processing needs. Generally speaking, the higher the power, the stronger the cutting and engraving capabilities.

For general small engraving tasks, 20W-100W of power is usually sufficient; for work that requires higher depth and efficiency, it is recommended to choose a higher power device.

4. Mechanical structure

Workbench size: Make sure the workbench size is suitable for your workpiece to avoid limiting the workspace.

Body stability: Choose a model with a sturdy structure to reduce vibration during engraving and improve engraving accuracy.

5. Software support

Make sure the device supports common design software, such as Adobe Illustrator, CorelDRAW, etc., for easy operation and design.

Check whether the model provides a user-friendly software interface and post-processing options.

6. Maintenance and service

Choose a manufacturer to provide high-quality after-sales service, such as technical support, training and equipment maintenance.

Consider the availability and replacement cycle of spare parts to ensure that the required replacement parts can be obtained quickly when necessary.

7. Budget considerations

Make a reasonable budget based on your financial situation, covering the price of the equipment itself as well as subsequent maintenance, consumables and operating costs.

Choose products with high cost performance, not just low prices, to ensure the long-term stability and reliability of the equipment.

8. Safety

Choose equipment that meets safety standards to ensure safety during operation, including laser protection, safe automatic shutdown and other functions.

Make sure the machine has a good ventilation system to avoid harmful fumes during laser processing.

By considering all of the above aspects and making rational choices, you can find the metal laser engraving machine that best suits your needs and ensures that your engraving work is efficient and precise. Click here to contact Suntop Laser now for more details.

There are several reasons to choose Suntop Laser as a brand of laser engraving machine:

Product quality

High-quality materials: Suntop Laser's equipment uses high-quality components and materials to ensure the durability and stability of the laser engraving machine.

Advanced technology: The company is committed to using the latest laser technology and manufacturing processes to provide high-performance engraving machines.

Excellent engraving accuracy

High-precision laser: Select high-quality fiber lasers to ensure the fineness and accuracy of engraving and cutting, suitable for a variety of precision work.

Easy-to-operate interface

User-friendly software: Suntop Laser's equipment is equipped with an intuitive operating interface and software, which is convenient for users to quickly get started and operate efficiently.

Support for multiple design software: Compatible with mainstream design software, it is convenient for users to create and design.

Multiple models and customized options

Diverse product lines: Suntop Laser offers a variety of models of laser engraving machines to meet different needs, including engraving and cutting of metal and non-metal materials.

Customized service: According to the specific needs of customers, Suntop Laser also provides customized solutions to meet the requirements of specific industries.

Excellent after-sales service

Technical support: Suntop Laser provides comprehensive technical support and training services to help customers solve problems encountered during use.

Warranty and maintenance: Provide reasonable warranty period and maintenance services to ensure the normal operation and long-term use of the equipment.

Excellent cost performance

Reasonable price: Suntop Laser provides customers with competitive prices through efficient production processes and cost control to ensure good cost performance.

Low operating cost: Its equipment can achieve efficient engraving and cutting, reduce material loss and energy consumption, and thus reduce long-term operating costs.

Combining the above points, Suntop Laser has become a good choice for laser engraving machine pre-purchase with its high-quality products, rich experience, customer-oriented services, and reasonable prices. Whether you are a small business or a large manufacturer, choosing Suntop Laser can effectively improve production efficiency and product quality.

1. What is a metal fiber laser engraving machine?

Metal fiber laser engraving machine is a kind of equipment that uses fiber laser technology to engrave and cut metal materials. It realizes precise engraving, lettering and cutting of metal surfaces by converting light energy into heat energy through a high-intensity laser beam.

2. What are the advantages of fiber laser engraving machine compared with other types of laser engraving machine?

Faster engraving speed: Fiber laser has higher beam quality for faster engraving speed.

Depth and Precision: Provides better engraving precision and depth control.

Lower Maintenance: Fiber lasers typically have a longer life and lower maintenance requirements.

Low Energy Consumption: Fiber lasers consume less energy than other lasers.

3. How easy is it to operate a metal fiber laser engraver?

Easy to operate, equipped with user-friendly operation interface and software that can simplify the operation steps. For novice users, they can usually get started quickly with the training and support provided by the manufacturer.

4. What are the maintenance requirements for a fiber laser engraver?

Regular Cleaning: Clean the laser and light guide system to maintain optimal performance.

Check the cooling system: Make sure the cooling system is working properly to prevent the laser from overheating.

Software Updates: Update the software regularly to improve performance and functionality.

5. What is the price range of a metal fiber laser engraver?

Prices vary by brand, model, power and features. Generally, small and mid-sized units range from a few thousand to tens of thousands of dollars, while high-end units can be more expensive.

6. What is the warranty period for the equipment?

The warranty is usually 2 years with lifetime maintenance. Make sure you understand the terms of the warranty and service at the time of purchase.

7. Is sample testing available?

Yes, sample testing services are available to allow customers to verify that the equipment meets their needs prior to purchase.

8. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time. For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

9. How about the warranty?

We have 2 years warranty and lifetime maintenance.

10. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.