Details Product Parameters Samples Video

Features of cnc fiber laser tube and sheet metal cutting machine

1. One machine with multiple functions can not only meet the cutting requirements of flat plates, but also meet the cutting requirements of round pipes and special-shaped pipes (square steel, flat iron, channel steel, square pipe), with high cost performance.

2. The chuck clamping system, the chuck self-adjusting center, automatically adjusts the clamping force according to the profile specifications, ensuring that the thin tube is clamped without damage.

3. With CYP pipe cutting software, it can directly accept drawings from 3D drawing software to 2D drawing software. Drawings can be displayed directly on the computer, which is more convenient and faster.

4. Auto-following system for calibrating and auto-following the wavy metal plate.

5. High-performance, imported original fiber laser with stable performance and a lifespan of more than 100,000 hours.

6. Adopt gantry type double gear rack, double servo motor drive, high torque, high inertia output, effectively improve the production efficiency of the equipment.

Details of cnc fiber laser tube and sheet metal cutting machine

1. Third generation aviation aluminum door frame

It is manufactured by aerospace standard and extruded by 4300 tons press. After aging treatment, its strength can reach 6061 T6, which is the highest strength among all gantries. Aviation aluminum has the advantages of good toughness, light weight, corrosion resistance, oxidation resistance and low density, which greatly improves the processing speed.

2. Machine tool

Adopting high-power machine tool with hollow structure, which effectively reduces the heat area during laser cutting. The machine tool will not be deformed in long-term use, and also ensures good cutting accuracy, which greatly improves the stability of the machine. It will not be deformed for at least 20 years of use.

3. Fiber laser source

Using the famous brand Raycus, MAX, IPG and other fiber laser, spot quality, stable output power, service life of up to 100,000 hours, a wide range of power options.

4. Fixture design

Both sides are designed with electric clamps, which can be automatically centered. The diagonal adjustable range is 20-200mm.

5. Auto-focus laser head

The focus scale can be flexibly adjusted, no need to manually focus, easy to operate. Control the vertical height, automatic focus, quickly complete the high-speed piercing of thick plates and automatically cut materials of different thicknesses.

6. Automatic lubrication system

Equipment timing quantitative lubrication system, not controlled by the position direction, reduce equipment maintenance time. Accelerate machine automation and extend the service life of drive mechanism. Equipped with independent warning system to provide early warning function.

Advantages of cnc fiber laser tube and sheet metal cutting machine

1. Better beam quality: smaller focused spot, finer cutting lines, smooth cut, beautiful appearance, no deformation, higher work efficiency and better processing quality.

2. Compact structure: fully integrated design, short installation time. After the equipment is in place, it can be put into production quickly.

3. Fine and excellent machining accuracy: The well-designed high-precision and high-rigidity transmission system makes the equipment have excellent motion rigidity, and high-speed cutting can still ensure accurate trajectory.

4. Optimized dust removal design: partitioned dust removal structure minimizes cutting dust on the processing site.

5. Flexible product processing mode: no need to prepare molds and auxiliary consumables, not limited by batches and graphics, graphics can be generated at any time and cut immediately.

6. Simple and easy-to-use control system: It adopts a professional cutting system, which is powerful, easy to learn and use, and can complete operations such as nesting and layout on the equipment.

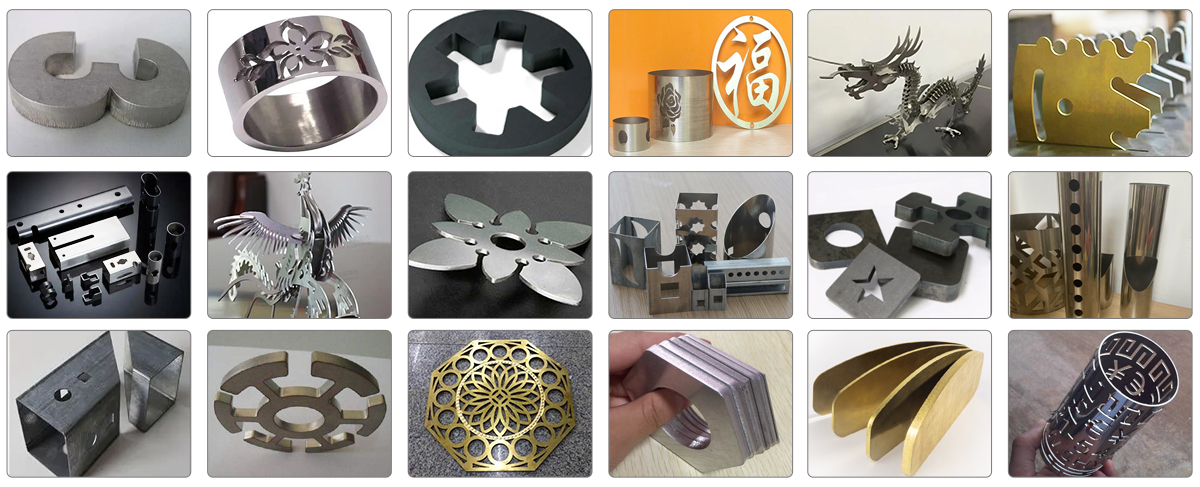

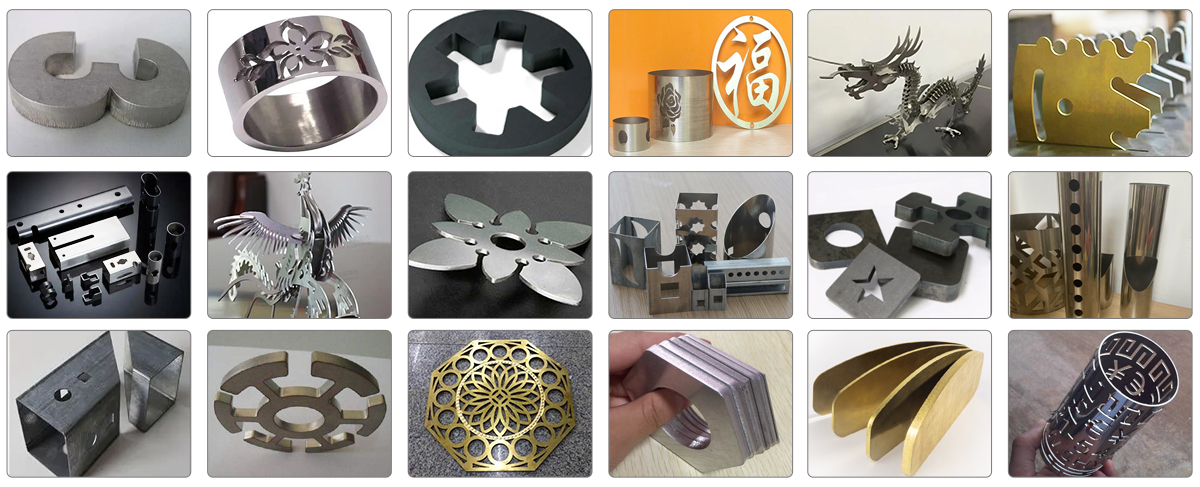

Cnc fiber laser tube and sheet metal cutting machine application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Widely used in sheet metal processing, round and square pipes, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobiles, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industries.

Parameters of cnc fiber laser tube and sheet metal cutting machine

Model | ST-FC3015R/ST-FC6015R/ST-FC6020R/ST-FC4020R |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (6000*1500mm, 6000*2000mm, 4000*2000mm) |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120meter/min |

Transmission system | Double rack & pinion and servo drive |

Tubes cutting capacity (standard) | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters |

Chuck type | Manual type or pneumatic self-centering chuck |

Maximum acceleration | 1.5G |

Power consumption | 6KW (based on laser power 1KW) |

Power supply | Three phase 380V/50Hz or 60Hz |

Machine weight | 7250Kg |

Overall size | 5050*2480*1830mm (L*W*H) |