1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

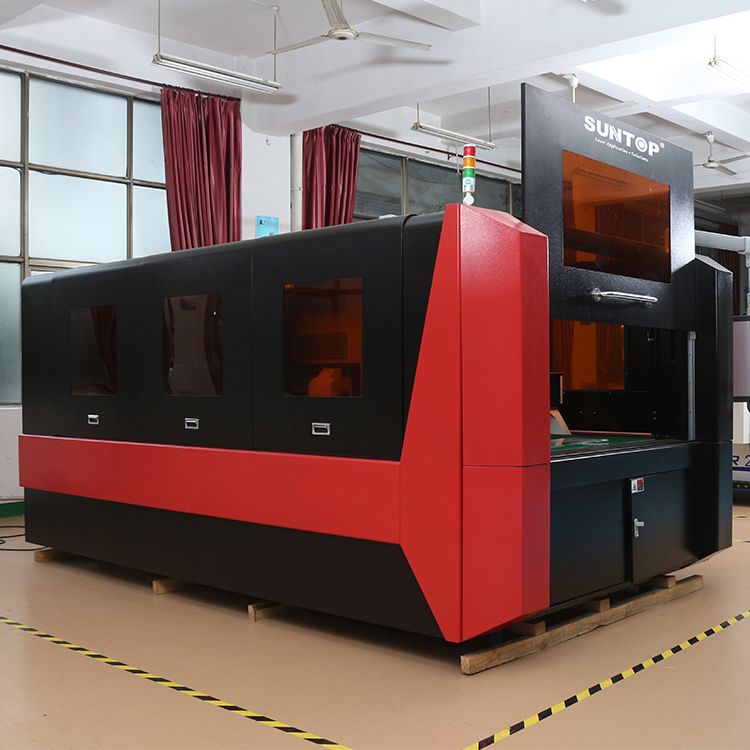

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. How does the device work?

The device first accepts the design file and converts it into a three-dimensional engraving path through the laser. Then the laser emits a high-precision laser beam to engrave the inside of the glass and finally form a preset pattern.

6. What are the advantages of this technology compared to traditional engraving methods?

Compared with traditional engraving methods, 3D laser internal engraving technology has the advantages of high precision, non-destructive processing, fast processing speed, complex patterns, and personalized customization.

7. Is it difficult to maintain a large-size 3D glass laser internal engraving machine?

Relatively speaking, equipment maintenance is relatively simple. Clean the laser head and lens regularly, and check the operation of the optical path and motion system. However, it is recommended to strictly follow the manufacturer's maintenance manual.

8. Does the laser engraving process produce any harmful substances?

Laser engraving generally does not produce harmful gases or waste, and is a relatively environmentally friendly processing method. However, to ensure safety, it is recommended to operate in a well-ventilated environment.

9. Can the depth and complexity of the engraving be adjusted?

Yes, different engraving depths and complexities can be achieved by adjusting the laser power, speed and robot path according to specific design requirements.

10. How cost-effective is it to use this device?

Although the initial investment is high, it has good cost-effectiveness in the long run due to its high performance, low post-processing requirements and expected market returns.

11. Is the operation of this device complicated?

It is simple, equipped with a user-friendly software interface, allowing operators to easily design and control the engraving process. After basic training, users can get started quickly.