Details Product Parameters Samples Video

Features of 3d laser engraving machine for crystal

1. Suntop independently researches and develops the design, which has functions such as engraving on the lower surface of the glass plate, marking on the surface, embossing, and glass drilling. It is specially designed for innovative processing of art glass.

2. No noise, fast speed, high precision, low energy consumption, low labor cost, maintenance-free, and environmental protection.

3. 24 hours of continuous operation, humanized system control and monitoring operation design, one-button to complete the engraving work, to avoid human error.

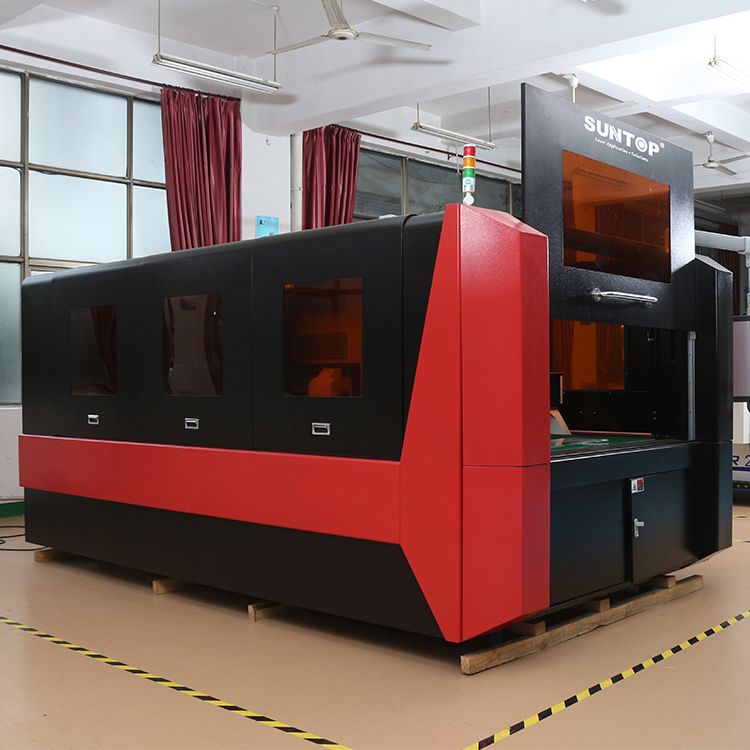

4. It adopts automatic positioning system, maintenance-free optical path system, high-precision motion control system, modular equipment, and easy maintenance.

5. It can be equipped with a fully enclosed laser protection cabinet that meets European CE standards.

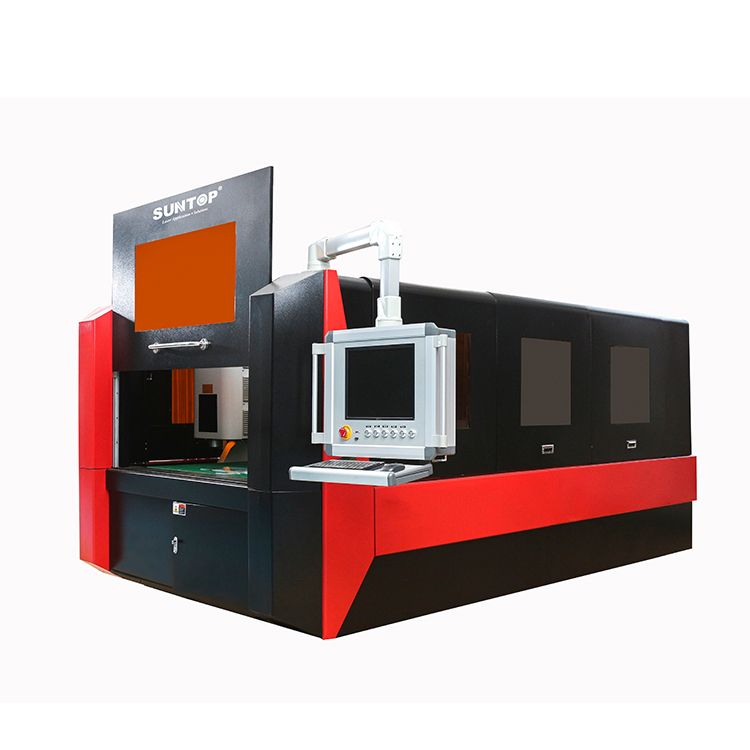

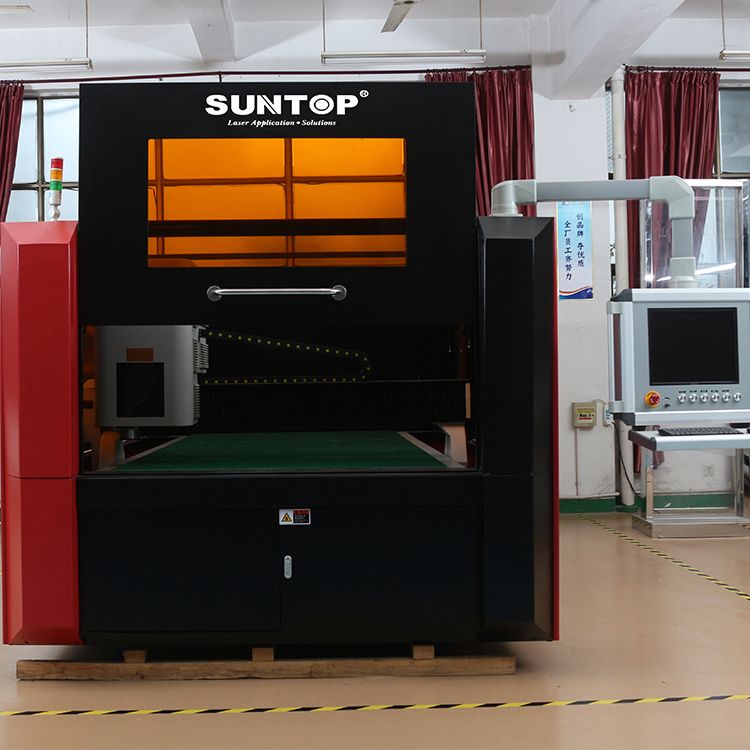

Details of 3d laser engraving machine for crystal

1. High-quality machine tools

The unique machine tool mechanism adopts self-service design, multiple imported servo motors, imported electrical components, and thickened workbench, which make the machine tool stable and durable.

2. 3D camera

Equipped with self-developed software and 3D camera, it can design delicate and precise human portraits.

3. Japanese servo motor

X and Y axes are equipped with Japanese servo motors with high precision, high speed, high torque, high inertia and stable performance, which ensure the high speed and acceleration of the whole machine.

4. Rack and pinion

Grinding gear technology is adopted to adapt to various use conditions, dustproof, and ensure long-term high-precision movement.

Advantages of 3d laser engraving machine for crystal

1. Good engraving quality, exquisite laser engraving effect, which cannot be compared with traditional glass processing methods.

2. The engraving range is wide, which can meet the needs of personalized engraving customization, and has a high engraving and marking speed.

3. It is suitable for mass production and supports placing multiple small pieces of glass of different sizes on the table for batch engraving at one time.

4. Intelligent, easy to operate, fast and convenient to work, no wearing parts.

5. Save energy, protect the environment, and change the traditional craft of art glass.

3d laser engraving machine for crystal application

Application materials

Suitable for crystal cube, transparent glass/arcylic and plastic,etc.

Application industry

It is widely used in 2D and 3D crystal photo engraving, artistic photo engraving, personalized crystal gift engraving, batch processing of high-precision crystal products, glass decoration, glass marking, high-grade glass anti-counterfeiting and other fields.

Parameters of 3d laser engraving machine for crystal

Model | ST-LCE2513 | ST-LCE30185 | ST-LCE1280 | ST-LCE3015 | ST-LCE-LA | ST-LCE-LB |

Max. engraving size (mm) | 1300*2500*110 | 1850*3000*80 | 800*1200*150 | 1500*3000*110 | 1830*2440*80 |

Average engraving speed | 180000-480000 dots/min | 220000-280000 dots/min |

Diameter for dots | 80-120μm | 40-80μm |

Mass production function | Mass production (engraving size can be customized) |

Laser medium | Laser diode |

Laser wavelength | 532nm |

Cooling system | Air cooling |

Working temperature | 10-45℃ |

Power supply | 380V/50-60HZ | AC220V or 110V ±10% |