Details Product Parameters Samples Video

Features of barcode laser marking

1. Integrated design, better meet the user's industrial production needs, small size, high space utilization.

2. Equipment adopts air-cooling technology, no need for water-cooling system, longer service life.

3. High beam quality, small spot size, narrow marking line width, more suitable for fine marking.

4. the machine adopts red light positioning system, easy positioning, high precision.

5. The machine can be equipped with other optional accessories according to customer's specific laser marking requirements, such as rotary device, 2D/3D worktable, pen turntable and other fixtures.

6. the use of professional industrial laser source, marking faster, marking consistency, high reliability, able to work continuously for 24 hours to meet the needs of large-scale processing and production.

Details of barcode laser marking

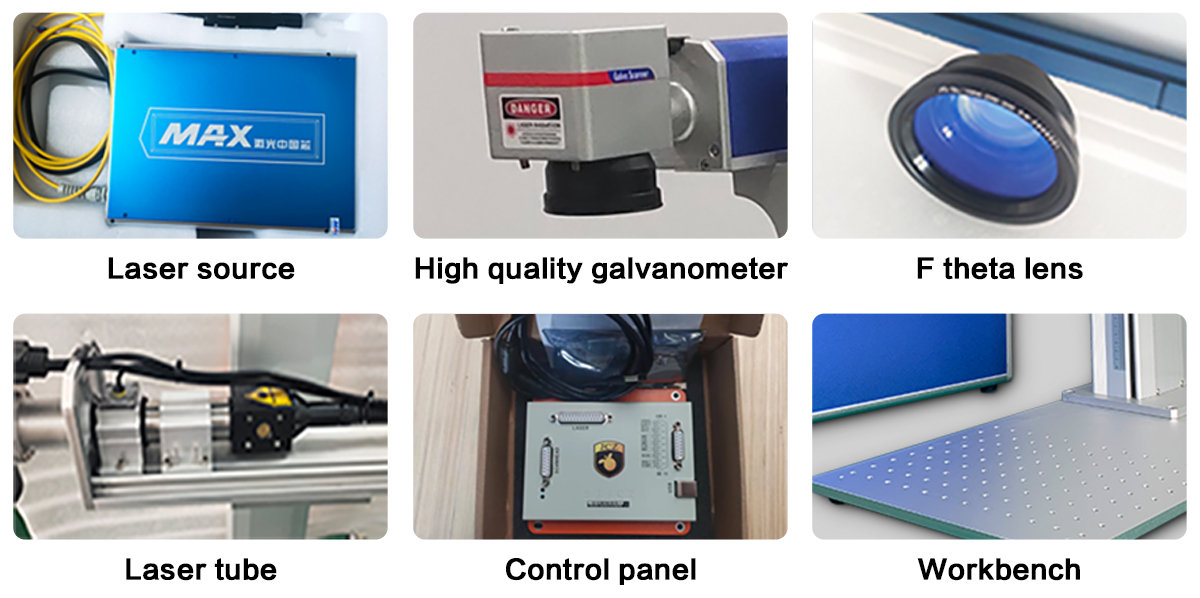

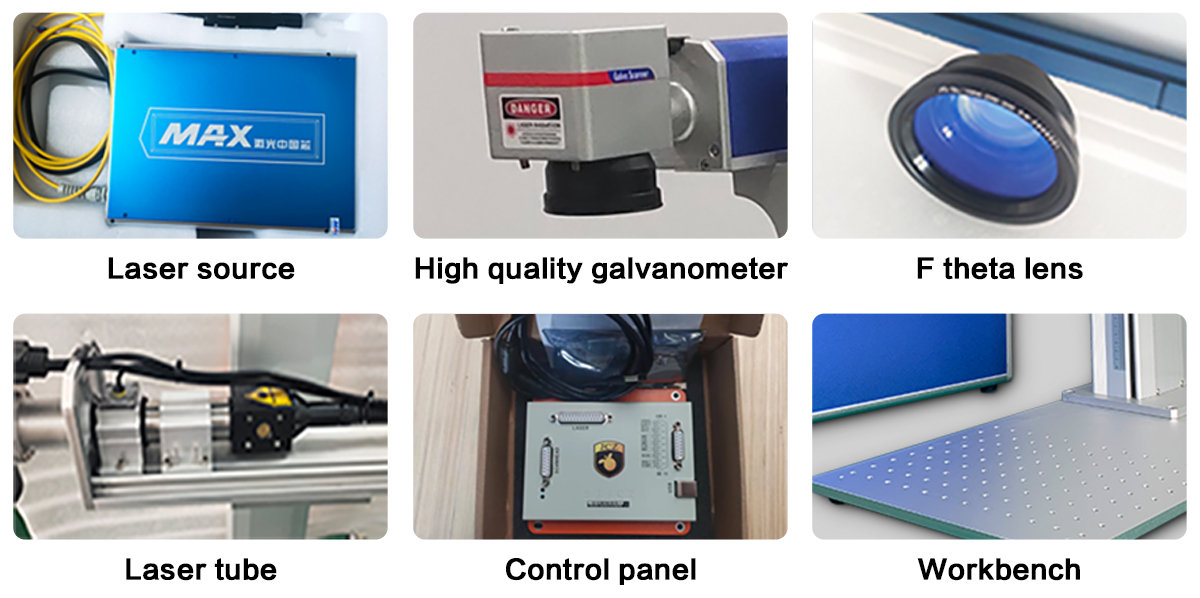

1. Laser

The core component is the laser, which is responsible for generating a high-power, highly stable laser beam, enabling the laser beam to perform marking operations at higher speeds and with greater precision.

2. Oscilloscope system

Responsible for controlling the trajectory and direction of the laser beam. By precisely controlling the movement of the galvanometer system, rapid and precise marking of the laser beam on the material surface can be realized.

3. field mirror

Used to diffuse the laser beam and form a certain spot size to adapt to different sizes of the marking area. By adjusting the focal length and angle of the field mirror, precise control of the spot size can be realized, so as to achieve efficient and high-quality marking effect.

4. Combining Mirror

It is used to combine the laser beam with the red light in order to observe the accuracy of the marking position during the marking process. Through the merging mirror and the laser beam to realize the optical path indication, so that the operator can more intuitively observe the state and position of the marking process.

5. Red light indicator

Used to indicate the position of the laser beam, through the closing mirror and the laser beam overlap, to realize the light path indication. In the marking process, the red light indicator can help the operator to quickly locate the marking position and improve the marking efficiency.

6. Control software

It is the core control part, which is used to generate and edit the marking pattern and control various operating parameters of the fiber laser marking machine. Through the control software, automated marking operation can be realized to improve production efficiency and quality.

Advantages of barcode laser marking

1. High-speed marking: Using a high-speed laser scanner, high-speed and efficient marking can be achieved in a short time. Compared with traditional inkjet coding or engraving technology, barcode laser marking is faster and improves production efficiency.

2. High-precision marking: The laser beam has high energy density and focus, which can achieve very fine marking lines. The barcode laser marking machine can achieve high-precision barcode marking to ensure the clarity and readability of the barcode.

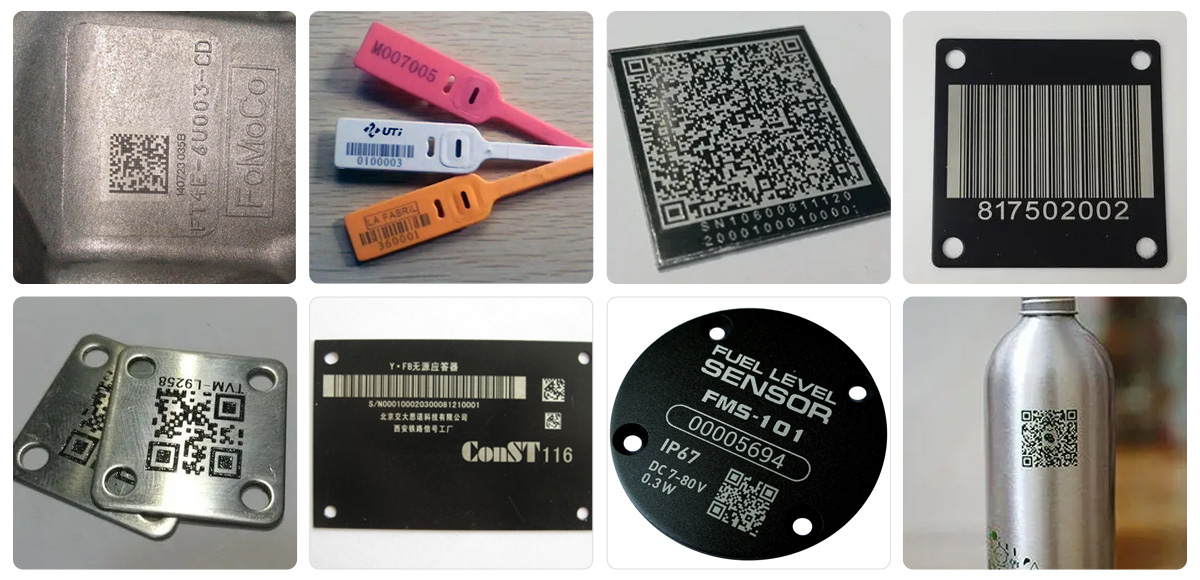

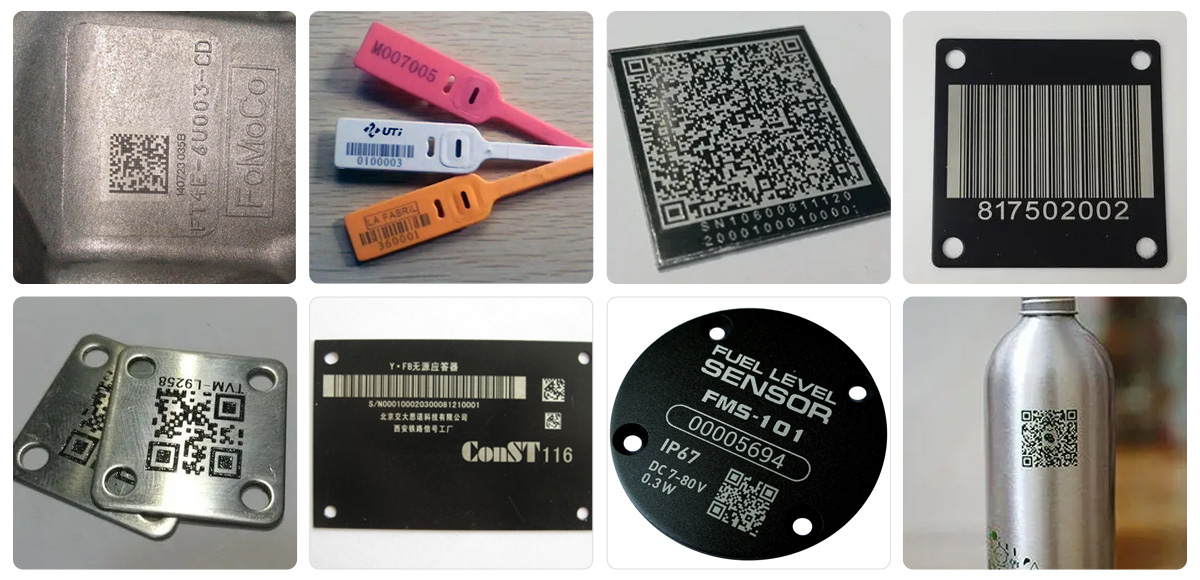

3. Multi-material adaptability: It can be applied to marking a variety of different materials, including metal, plastic, etc. Whether the surface is smooth or rough, laser marking can achieve clearly visible barcodes.

4. Long-term effectiveness and durability: Using laser beams for barcode marking can achieve a non-contact marking process without causing physical damage to the product surface. Laser-marked barcodes are highly durable and are not easily worn, faded or blurred, ensuring long-term readability of the barcode.

5. High security and anti-counterfeiting capabilities: Tiny and complex marking lines can be realized, adding security and anti-counterfeiting capabilities to barcodes. The special barcode structure and marking method can effectively prevent counterfeiting and tampering and improve product safety.

6. Environmentally friendly and energy-saving: No additional ink or chemicals are required and no pollutants are produced. Laser marking has relatively low energy consumption, saving energy and resources.

7. Traceability and data management: It is possible to mark unique identification codes on products to achieve product traceability. By integrating with the data management system, comprehensive product information recording and management can be achieved.

Application materials of barcode laser marking

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc., and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.

Application industry of barcode laser marking

Used in electronic components, integrated circuits (ICs), electrical appliances, mobile communications, hardware products, tool accessories, precision instruments, glasses and watches, jewelry, auto parts, plastic buttons, building materials, PVC pipes, medical equipment and other industries. Applicable materials include: common metals and alloys (iron, copper, aluminum, magnesium, zinc and other metals), rare metals and alloys (gold, silver, titanium), metal oxides (all metal oxides are acceptable), special surfaces Treatment (phosphating, aluminum anodization, electroplating surface), ABS material (electrical appliance casing, daily necessities), etc.

Parameters of barcode laser marking

Laser Power | 20W | 30W | 50W | 60W |

Model | ST-FL20P | ST-FL30P | ST-FL50P | ST-FL60P |

Max Marking Range | 110*110mm /150*150mm | 200*200mm | 300*300mm | 450*450mm |

Depth of Single Marking | 0.01mm | 0.03mm | 0.06mm | 0.07mm |

Same pattern marking efficiency | 10s | 7 s | 4s | 3s |

Whole Machine Power | 600W/h | 800W/h | 1000W/h | 11000W/h |

Laser Type | Fiber Laser |

Laser Source | MAX Brand ( Raycus can choose ) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Working Accuracy | ±0.002MM |

Marking Speed | 0-7000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 1064nm |

Minimum Font for Marking | 0.15mm |

Working Voltage | 220V±10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 50KG |

Machine Dimension | 420*300*550mm (L*W*H) |