Details Product Parameters Samples Video

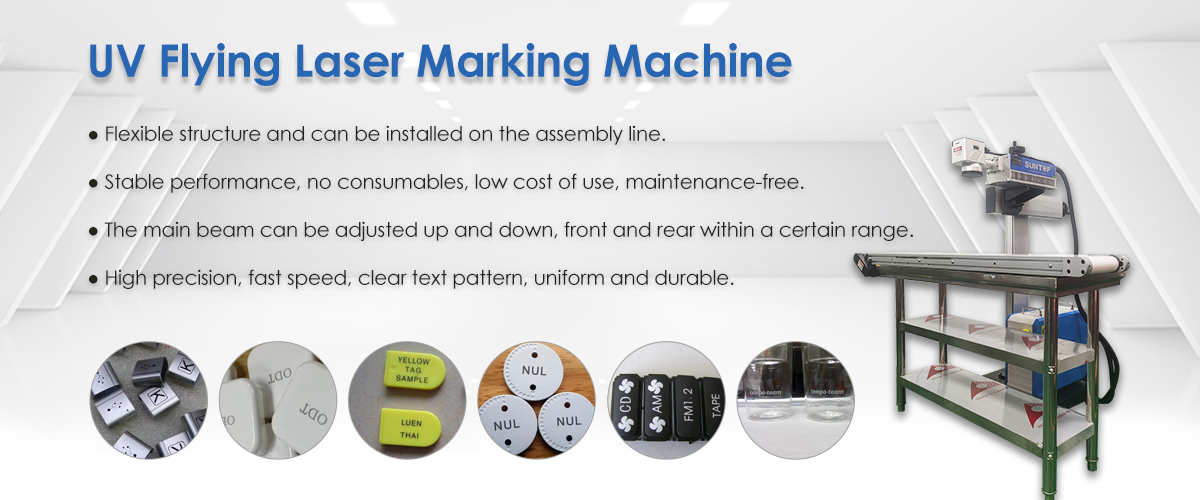

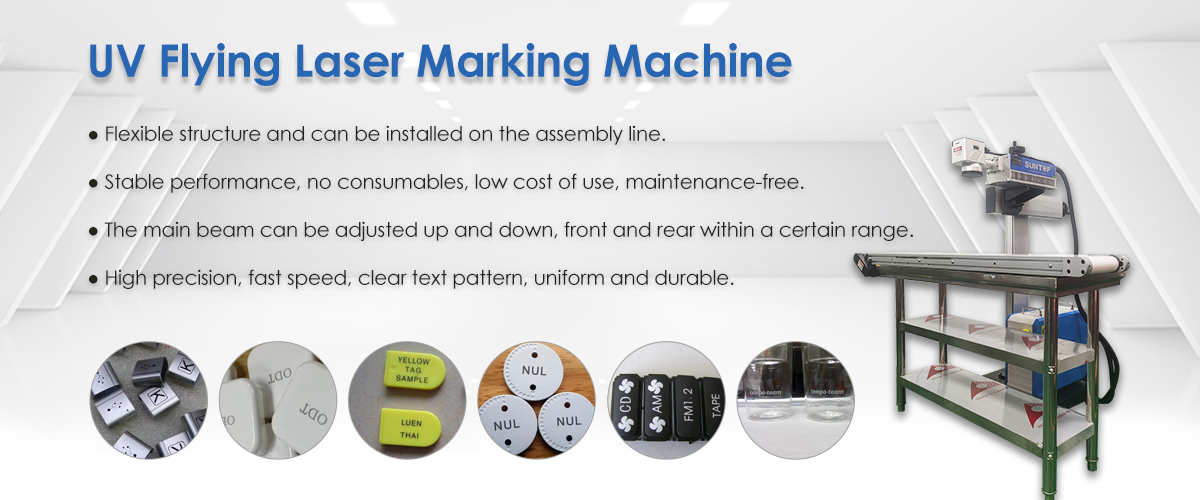

Features of 2d barcode laser marking

1. The structure is flexible, the floor space is small, and the professional branch is cooled by constant temperature water, allowing it to work efficiently and stably even under high ambient temperatures.

2. It can be easily installed on the assembly line and is adjustable.

3. It is compatible with a variety of focusing lenses and can adjust the light output in various directions to meet the needs of different application scenarios.

4. The stable and lightweight main beam lifting mechanism can adjust the main beam within a certain range, both vertically and horizontally.

5. It has high electro-optical conversion efficiency, low power consumption, long life, and saves customers a significant amount of processing costs.

6. It uses a professional industrial laser source, resulting in faster marking speed, good marking consistency, high reliability, and the ability to work continuously for 24 hours to meet the needs of large-scale processing and production.

Advantages of 2d barcode laser marking

1. High precision: It has high marking accuracy and resolution, and can achieve subtle pattern and text marking, ensuring clear and precise marking effects.

2. High-speed marking: With fast marking speed, it is suitable for mass production and rapid marking requirements, improving production efficiency.

3. Wide application: Suitable for marking a variety of materials, including plastics, glass, ceramics, metal coatings, etc. It can achieve high-quality marking without damaging the material surface.

4. High contrast and durability: The marking results have high contrast, are clearly visible, and have good durability and are not easy to wear and fade.

5. Non-contact marking: The laser beam does not directly contact the workpiece surface during the marking process, reducing mechanical wear and damage, and also reducing the need for cleaning and maintenance.

6. Environmental protection and energy saving: laser light source is used for marking, without the use of chemicals, no waste water and gas emissions, and meets environmental protection requirements.

7. Easy operation: It has a simple operation interface and control system, is easy to operate, can adjust marking parameters, and supports automated production line integration.

Main application of 2d barcode laser marking

1. Product traceability: The QR code laser marking machine can engrave the QR code pattern on the surface of the product to facilitate production and traceability management of the product.

2. Anti-counterfeiting marking: The QR code laser marking machine can carve a high-precision anti-counterfeiting QR code pattern on the surface of the product, effectively curbing the emergence of counterfeit and shoddy products.

3. Marking: The QR code laser marking machine can mark the surface of the workpiece to facilitate the automated control and management of the production line.

4. Medical device marking: QR code laser marking machine can mark the surface of medical devices to facilitate the management and traceability of the devices.

Application materials of 2d barcode laser marking

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry of 2d barcode laser marking

Widely used in electronics, instruments, communication equipment, packaging, beverages, batteries, sanitary ware, electronic components (IC), electrical appliances, mobile communications, automobiles, medical equipment and other industries.

Parameters of 2d barcode laser marking

Model | ST-UV03F | ST-UV05F | ST-UV08F |

Laser Power | 3W | 5W | 8W |

Max. marking range | 110*110mm | 150*150mm | 180*180mm |

Output power | >3W@30KHZ | >5W@40KHZ | >8W@40KHZ |

Maximum pulse energy | 0.1MJ@30KHZ | 0.12MJ@40KHZ | 0.14MJ@40KHZ |

Pulse duration | <15NS@30KHZ | <18NS@40KHZ | <21NS@40KHZ |

1/e2 beam diameter at output | 0.7mm | 0.8mm | 0.9mm |

Laser Type | UV laser |

Laser source | GAIN(JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | all metal material and all non metal material |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 150KG / 180KG |

Machine size | 510*660*1470mm (L*W*H) |