Details Product Parameters Samples Video

Features of uv laser engraver

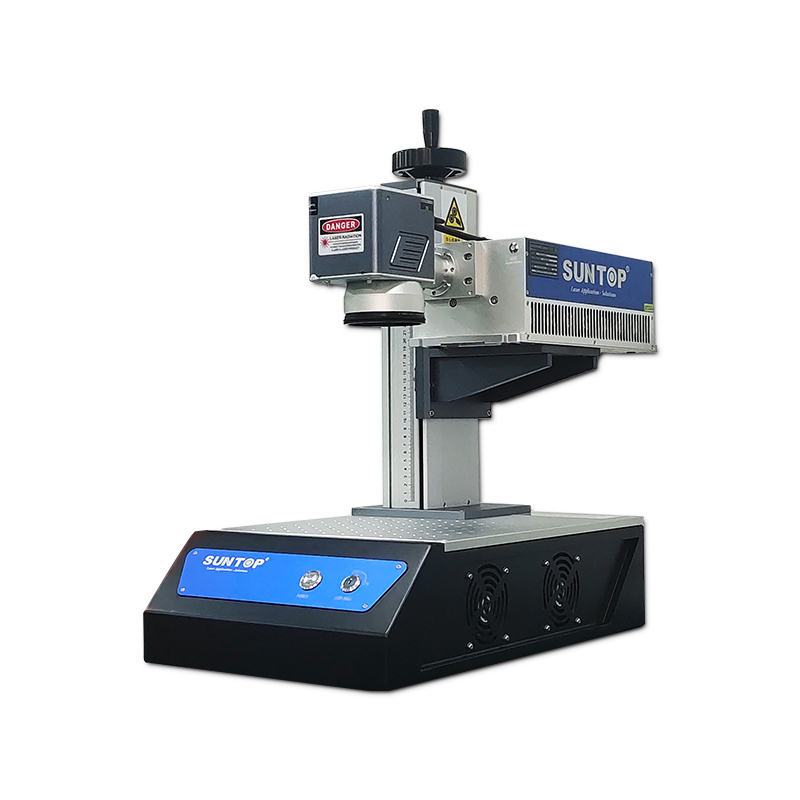

1. The whole machine has stable performance, compact structure, small size, light weight, and is easy to carry.

2. The built-in laser diode technology is used to avoid the influence of fiber jitter on the output laser.

3. The quality of the ultraviolet light beam is excellent enough to ensure the stability and reliability of mass production and meet the special manufacturing and processing requirements under harsh industrial conditions.

4. It is cooling laser, which has very good and smooth marking on heat-sensitive plastic material without any damage to the surface of the material.

5. Suntop Fiber Laser Marking Machine is subject to strict aging tests and continuous 24-hour laser beam output before leaving our factory to ensure 100% machine stability.

Details of uv laser engraver

1. Brand laser

Adopt high quality light source with good spot quality and small focusing spot to realize super fine marking.

2. High-speed scanning galvanometer

High precision laser scanning oscillator, small size, fast speed and good stability.

3. High transmission field lens

4. Adopt high transmission coating field mirror, greatly improve the edge light gathering ability, high light transmission rate, good marking effect.

4. Built-in air-cooling

Built-in air-cooling design, better heat dissipation performance.

5. Workbench

Humanized design, multi-positioning arrangement, simple interface, flexible adjustment of product positioning.

Advantages of uv laser engraver

1. Adopt imported original UV laser, high beam quality, small focusing spot, ultra-fine marking and high definition.

2. Built-in laser diode technology, avoiding the impact of fiber jitter on the output laser.

3. It is cooling laser, very good marking effect on heat-sensitive plastic material, very smooth and no damage to the material surface.

4. It adopts imported scanning head, small size, fast speed and good stability.

5. One piece modular design, stable performance, compact structure, small size, easy to maintain as well as move.

UV laser engraver application

Application materials

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry

Especially suitable for the high-end market of ultra-fine processing, skin care cosmetics, medical drugs, food, silicon wafer micro-hole, blind hole processing, glass products, metal products, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Parameters of uv laser engraver

Model | ST-UV03P | ST-UV05P |

Laser Power | 3W | 5W |

Max. marking range | 110*110mm | 150*150mm |

Output power | >3W@30KHZ | >5W@40KHZ |

Maximum pulse energy | 0.1MJ@30KHZ | 0.12MJ@40KHZ |

Pulse duration | <15NS@30KHZ | <18NS@40KHZ |

1/e2 beam diameter at output | 0.7mm | 0.8mm |

Laser Type | UV laser |

Laser source | GAIN (JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Water Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | all metal material and all non metal material |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 48KG |

Packaging Dimension | 320mm*7549mm*668mm (L*W*H) |