When it comes to cleaning surfaces, traditional methods like scrubbing, blasting, or using chemicals can be time-consuming, labor-intensive, and potentially harmful to the environment. However, with the advancement of technology, laser cleaning machines have emerged as a more efficient and eco-friendly alternative. So, what exactly can you clean with a laser cleaning machine?

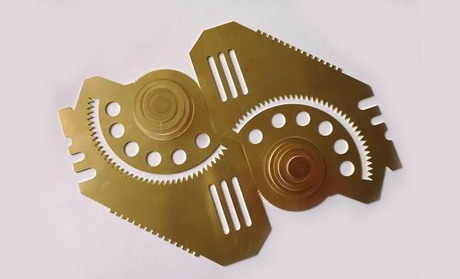

Metal Surfaces

One of the most common applications of laser cleaning machines is the cleaning of metal surfaces. Whether it's rust, paint, or grease, a laser cleaning machine can effectively remove contaminants without damaging the underlying metal.

Stone and Concrete

Laser cleaning machines are also suitable for cleaning stone and concrete surfaces. They can remove graffiti, dirt, and other unwanted substances from these surfaces without causing any damage.

Automotive Parts

Automotive parts often require thorough cleaning to ensure optimal performance. Laser cleaning machines can be used to clean engine components, brakes, and other parts without the need for harsh chemicals or abrasive methods.

Historical Artifacts

Preserving historical artifacts is a delicate process that requires gentle yet effective cleaning methods. Laser cleaning machines can safely remove dirt, grime, and other contaminants from artifacts without causing any damage to the original material.

Electronic Components

Cleaning electronic components is crucial for maintaining their functionality. Laser cleaning machines can remove dust, debris, and other contaminants from circuit boards and other electronic parts without the risk of damage from traditional cleaning methods.

Medical Equipment

Keeping medical equipment clean and sterile is essential for patient safety. Laser cleaning machines can effectively clean medical instruments and equipment without the use of harsh chemicals that could compromise the integrity of the equipment.

Laser cleaning machines offer a versatile and efficient solution for cleaning a wide range of surfaces and materials. From metal and stone to automotive parts and electronic components, these machines provide a safe and effective cleaning method that is environmentally friendly. With their precision and non-contact cleaning capabilities, laser cleaning machines are becoming an increasingly popular choice for industries looking to improve their cleaning processes.