Choosing the right laser marking machine is a multi-faceted decision, depending on your specific needs and application scenarios. Here are some key considerations to help you choose the most suitable laser marking machine:

1. Application requirements

Material Type: Determine the type of material you need to mark, such as metal (stainless steel, aluminum, etc.), plastic, glass, rubber, etc. Different materials require different types of lasers.

Marking depth and precision: Determine the required marking depth and precision (such as clear text, complex patterns, etc.) according to product requirements.

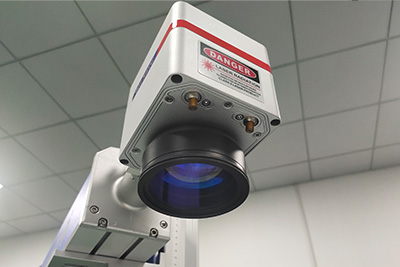

2. Laser type

Fiber laser marking machine: suitable for metal materials, fast marking speed, low maintenance cost, suitable for industrial applications.

CO2 laser marking machine: suitable for non-metallic materials, such as plastic, wood, leather, etc., widely used in packaging and jewelry.

Green laser marking machine: mainly used for high-precision marking of certain special materials (such as certain crystals and glass).

3. Marking speed and efficiency

Marking speed: ensure that the selected equipment can meet the production efficiency requirements to improve the overall efficiency of the production line.

Continuous working capability: If long running time is required, it is important to know the durability and failure rate of the equipment.

4. Budget

Equipment cost: The price of laser marking machines varies by brand, type and features. Define a budget and consider whether you want to buy brand new or used equipment.

Maintenance and operating costs: In addition to the initial investment, consider the day-to-day overhead of consumables (e.g., electricity needed to run the laser), maintenance and technical support.

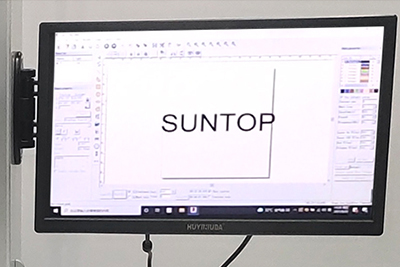

5. Operation and software

User-friendliness: Choose a machine that is easy to operate and manage, especially if the operators have different technical backgrounds.

Software compatibility: Ensure that the control software of the laser marking machine is compatible with your design software (e.g. AutoCAD, CorelDRAW, etc.).

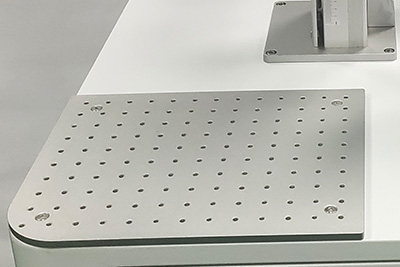

6. Equipment size and work area

Working area: according to your product size and marking needs, choose the appropriate size of the working area.

Space occupied by the equipment: Considering the working environment, choose the equipment size suitable for the space.

7. After-sales service and technical support

Manufacturer Reputation: Choose a well-known laser marking machine manufacturer, they usually provide better technical support and after-sales service.

Warranty and service agreement: Make sure you understand the warranty policy and follow-up support services of the equipment.

8. Industry application requirements

Industry standards and compliance: certain industries have specific requirements for marking quality and standards, make sure the equipment you choose can meet these requirements.

9. Personalization and customization needs

Customized marking: If you need personalized customized marking (e.g., serial number, two-dimensional code, etc.), make sure that the laser marking machine can meet these requirements.

Choosing the right laser marking machine requires comprehensive consideration of a number of factors, including your specific application, materials, budget and so on. If possible, it is recommended to test samples before purchase to ensure that the equipment can meet your expectations. Click here to consult Suntop Laser today for professional advice and opinions.