Details Product Parameters Samples Video

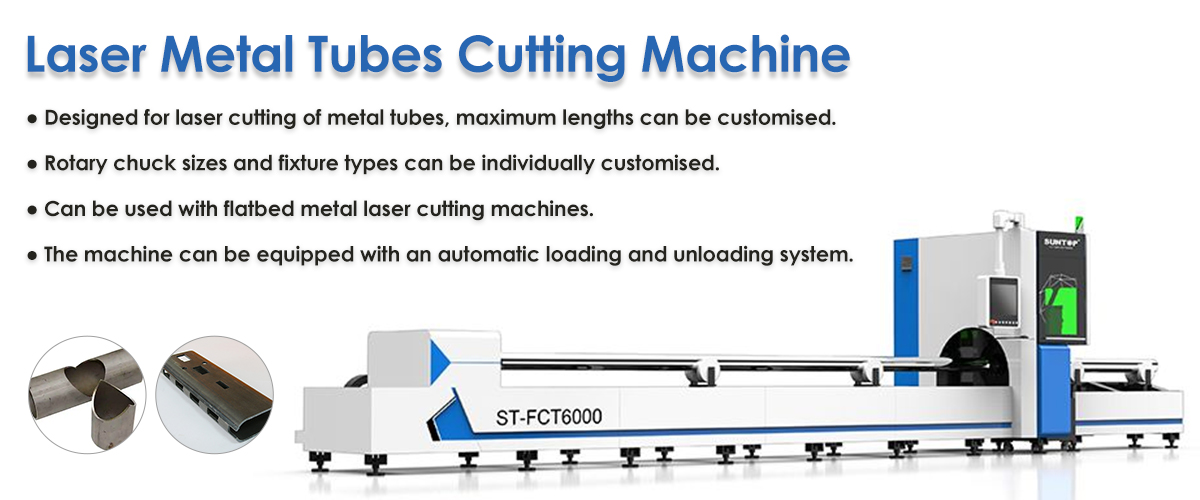

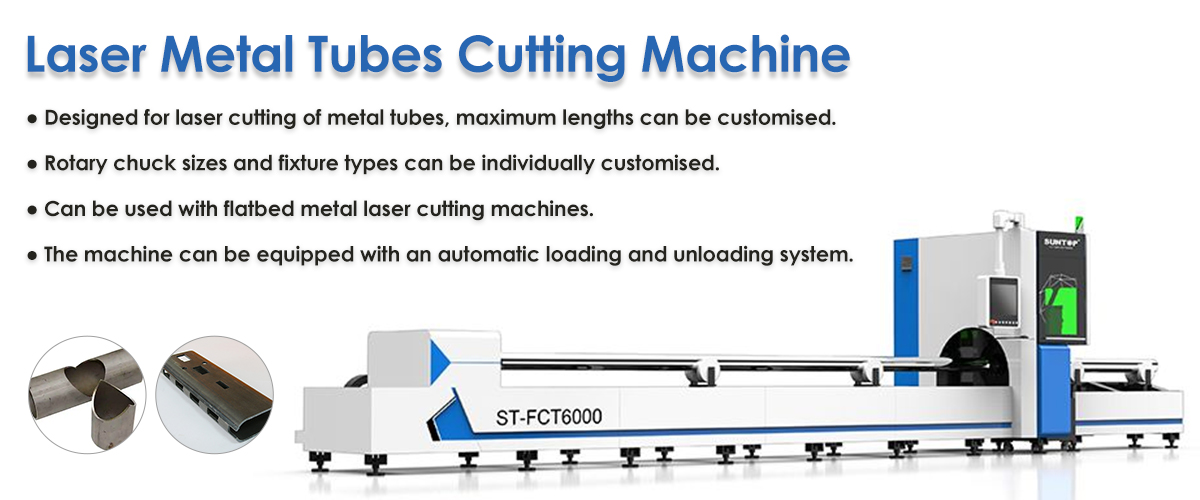

Features of laser tubes cutting machine

1. Laser pipe cutting machine adopts electric type pipe clamps, suitable for round, square, rectangular, oval, I-beam, channel, angle and other types of shaped pipes, stable and will not shift.

2, high performance, using the original imported package fiber laser, stable performance, good beam quality, high precision, life expectancy up to 100,000 hours.

3. low cost, power consumption of about 0.5-1.5KW/H, can cut various metal tubes by blowing compressed air.

4. Adopt special software for pipe cutting, can design or process graphics or text instantly, flexible and convenient, effectively save material and improve cutting efficiency.

5. Adopt precision rack drive method, easy maintenance, basically maintenance-free.

6. chuck diameter size and fixture can be customized according to the specific specifications of the pipe provided by the customer.

7. Pneumatic chuck structure, automatic clamping automatic positioning center, automatic push and rotation, etc.

Details of sheet metal and laser tubes cutting machine

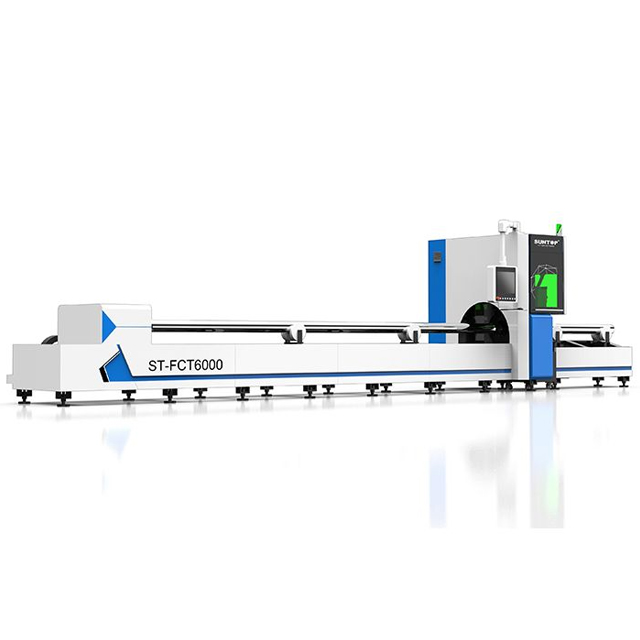

1. Pneumatic chuck

Easy to install, no consumption and wear, through the size of air pressure to control the degree of workpiece clamping, can be easily controlled to ensure the smoothness of feeding and cutting accuracy.

2. Automatic lubrication system

Ensure the normal high-speed operation of the equipment, with abnormal alarm and liquid level alarm, etc., to ensure the accuracy and extend the service life of the transmission machine.

3. Safety follower module

Configured with imported follower capacitor adjuster, the laser head and workpiece cutting distance is always maintained to reduce the risk of collision, and has a touch plate stop function.

4. Cast aluminum beam

The overall cast aluminum beam, refined by artificial aging and solution treatment, so that the beam has excellent integrity, rigidity, and good toughness.

Light weight, anti-corrosion, anti-oxidation, low density, under the premise of meeting the precision, can realize all kinds of graphics fast cutting.

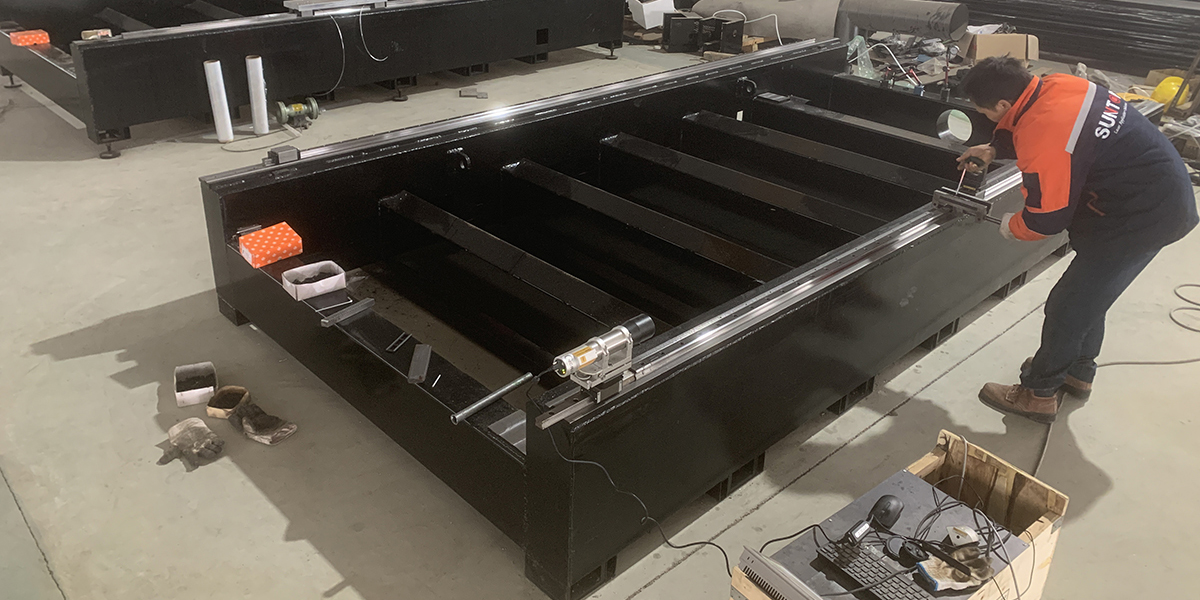

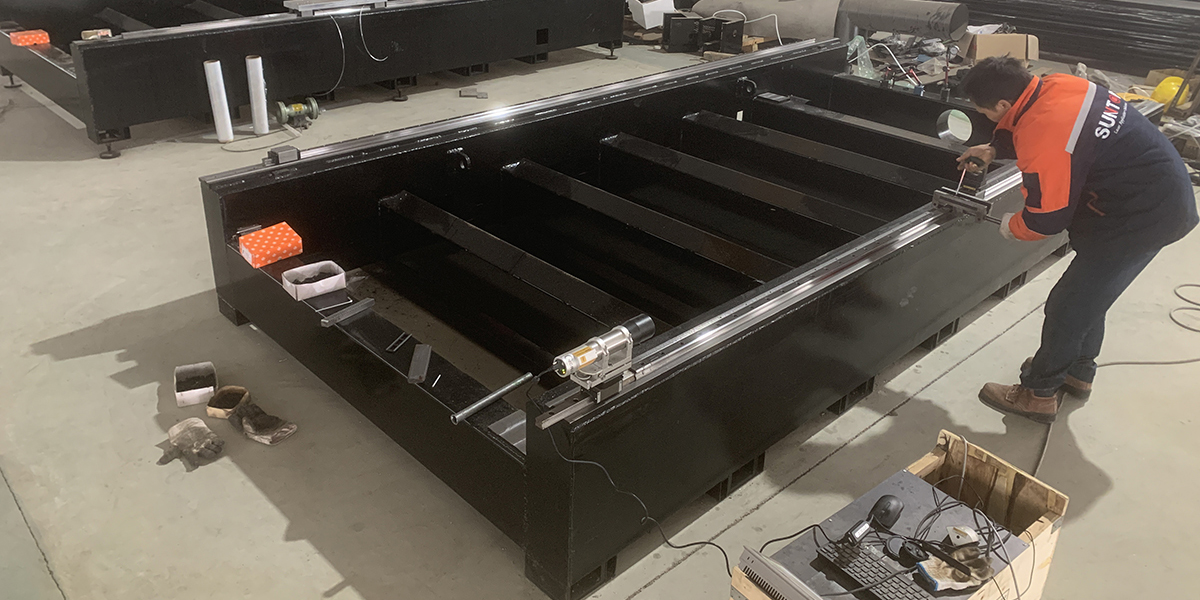

5. Heavy-duty bed design

High power machine with hollow structure, effectively reduce the heat area in the laser cutting process. Steel plate is welded together, and the weight of a single machine is 4 tons. The machine will not be deformed in long-term use, and also ensure good cutting accuracy, which greatly improves the stability of the machine. At least 20 years of use will not be deformed.

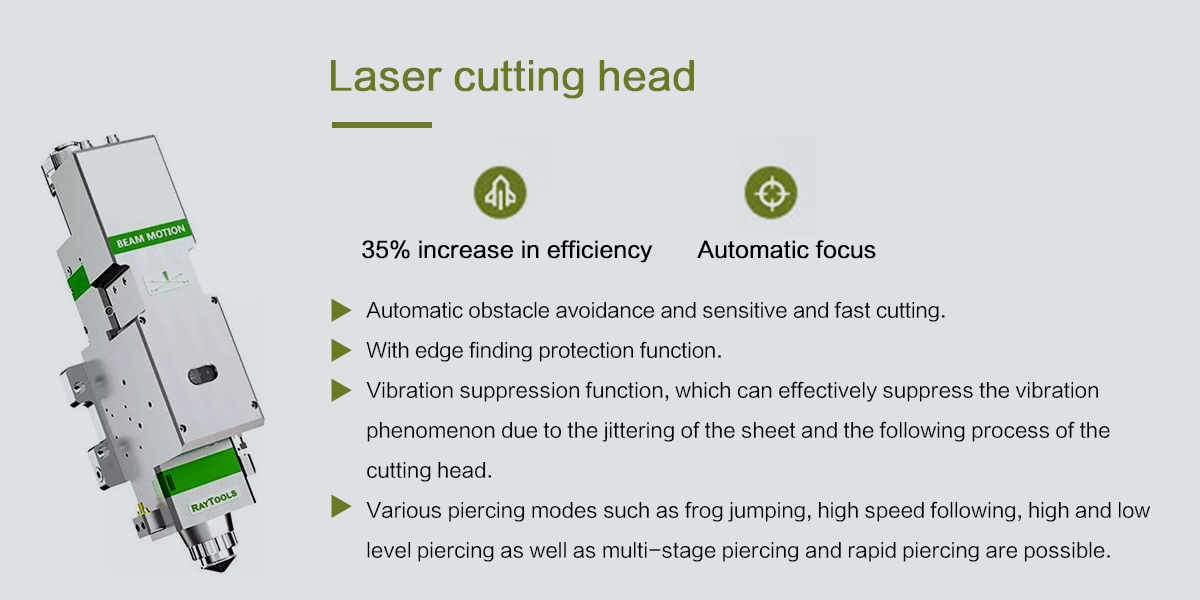

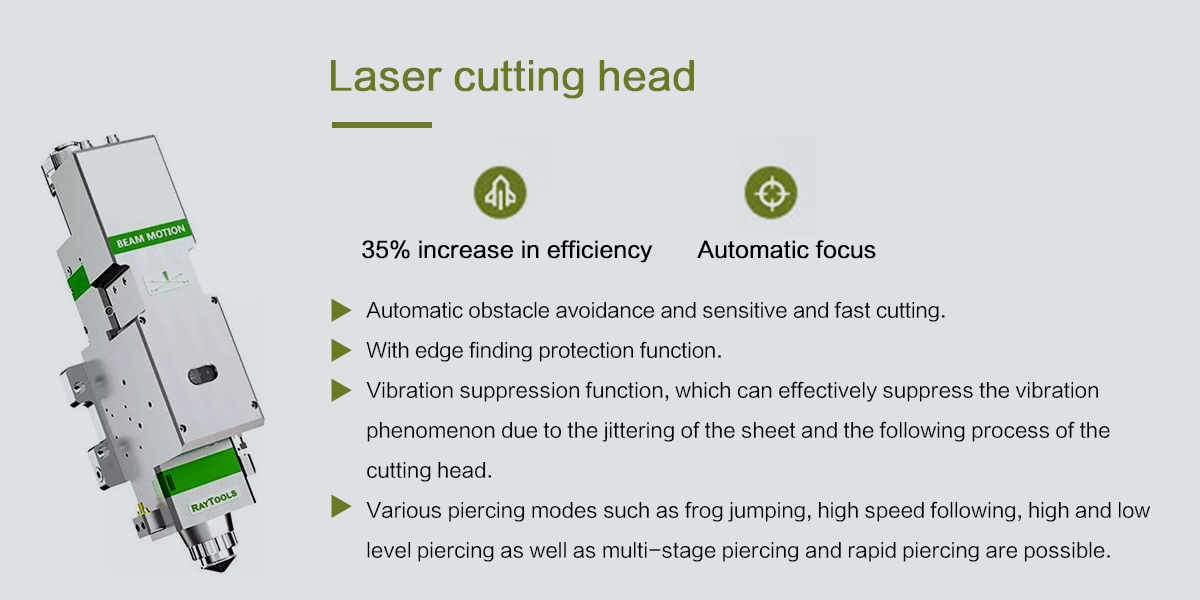

6. Laser cutting head

No manual manual focus, the software automatically adjusts the focus mirror. Control the up and down height to achieve automatic perforation and cutting of different thickness plates. Automatic adjustment of the focusing lens is ten times faster than manual adjustment.

Advantages of laser tubes cutting machine

1. Laser pipe cutting machine in the processing of metal materials, high cutting accuracy, flat kerf, no burr, will not damage the raw material.

2. Laser cutting heat impact is small, almost no thermal deformation when cutting, no oxidation on the fracture surface.

3. High working efficiency, and can work continuously for a long time, suitable for mass processing of pipes, can effectively reduce the investment of labor costs.

4. Can be equipped with automatic loading and unloading device, the whole set of equipment can reduce the manual handling to a certain extent, significantly reduce the cost of investment.

5. High flexibility clamping chuck, high precision, high control of pipe clamping force, avoid pipe clamping deformation phenomenon.

6. High flexibility in cutting pipe, professional cutting software, can cut any shape that has been programmed on the metal pipe, can finish cutting in any direction, reducing the number of molds used.

7. Various kinds of different pipe diameters can be freely switched without changing clamps.

Laser tubes cutting machine application

Application materials

Suitable for cutting the stainless steel, carbon steel, silicon steel, aluminium alloy, titanium alloy, galvanized steel, pickle steel, aluminium-plating Zinc tubes, metallic copper, brass and other rare metal tubes.

Application industry

It is widely used in laser cutting processing of various metal tubes, such as mold laser cutting, electronic applications, aviation, machinery, elevator, automobile, turbine, cutting tool, subway parts, petroleum machinery, food machinery, handicraft, tool processing, decoration, lamp post, steel furniture, decoration, advertising, metal outside processing and other metal tube related industries.

Parameters of laser tubes cutting machine

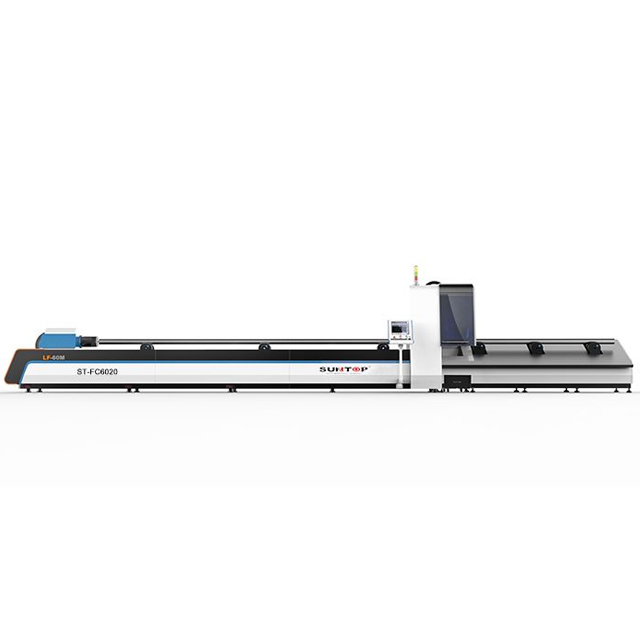

Model | ST-FCT6000/ST-FCT3000 |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Tubes cutting capacity | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters (optional) |

Chuck type | Manual chuck type or pneumatic self-centering chuck (optional) |

Power consumption | 6KW (based on laser power 1KW) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 4850Kg |

Machine dimension | 12000*1650*2280mm (L*W*H) |