Details Product Parameters Samples Video

Features of laser cutting machine metal

1. The front and rear chucks and drill bits of this machine are driven by servo motors, cutting without shaking, with high precision and good synchronization.

2. High-quality guide rail and rack and pinion transmission, high rigidity, smooth operation, low noise, smooth operation, and reduced impact and vibration.

3. Electric self-centering chuck, without manual adjustment, any material with a diameter of 20-150mm does not need to be centered.

4. Auto-following system for calibrating and auto-following the wavy metal plate.

5. It has an automatic alarm function for the abnormal working state of the equipment, and pushes it to the operation interface through the control center, which improves the efficiency of equipment abnormal troubleshooting, reduces potential safety hazards, and reduces maintenance costs.

6. With professional software operating system, you can design various graphics or text at will, which is convenient for editing and modifying the cutting path. Scientific man-machine interface, flexible processing, simple operation and high efficiency.

Details of laser cutting machine metal

1. Fiber laser source

Using the famous brand Raycus, MAX, IPG and other fiber laser, spot quality, stable output power, service life of up to 100,000 hours, a wide range of power options.

2. Third generation aviation aluminum door frame

It is manufactured by aerospace standard and extruded by 4300 tons press. After aging treatment, its strength can reach 6061 T6, which is the highest strength among all gantries. Aviation aluminum has the advantages of good toughness, light weight, corrosion resistance, oxidation resistance and low density, which greatly improves the processing speed.

3. Segmented rectangular tube welding machine

The internal structure of the bed adopts aircraft metal honeycomb structure, which is welded by multiple rectangular tubes. The tube is equipped with reinforcement bars, which increases the strength and tensile strength of the bed, and also increases the resistance and stability of the guide rail, effectively avoiding the deformation of the bed. High strength, stability, tensile strength, to ensure the use of 20 years without deformation

4. Auto-focus laser head

The focus scale can be flexibly adjusted, no need to manually focus, easy to operate. Control the vertical height, automatic focus, quickly complete the high-speed piercing of thick plates and automatically cut materials of different thicknesses.

5. Transmission and precision

Suntop fiber laser cutting machine is equipped with Taiwan YYC rack and pinion, Japan Yaskawa motor and French reducer.

6. Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

7. Automatic Lubrication System

Timed and quantitative lubrication system for the equipment, not controlled by the position and direction, reduces the maintenance time of the equipment. Accelerate machine automation and extend the life of the drive mechanism. Equipped with independent warning system to provide early warning function.

Advantages of laser cutting machine metal

1. High-performance, imported original fiber laser with stable performance and a lifespan of more than 100,000 hours.

2. One machine with two functions, saving cost. Cutting metal sheets and pipes, with a wide range of uses, can save more than 50% of the space and effectively improve productivity.

3. It has a large working width and is equipped with a pipe cutting device. It can cut both flat plates and round pipes. It has stronger applicability and can save the drilling process. It is suitable for mass production, with high efficiency and high stability.

4. High cutting precision, fast speed, good quality, small kerf, small deformation, smooth and beautiful cutting surface, no need for follow-up processing.

5. The perfect numerical control system and professional auxiliary control software make the work flexible and efficient, and the machine operation is simple and convenient.

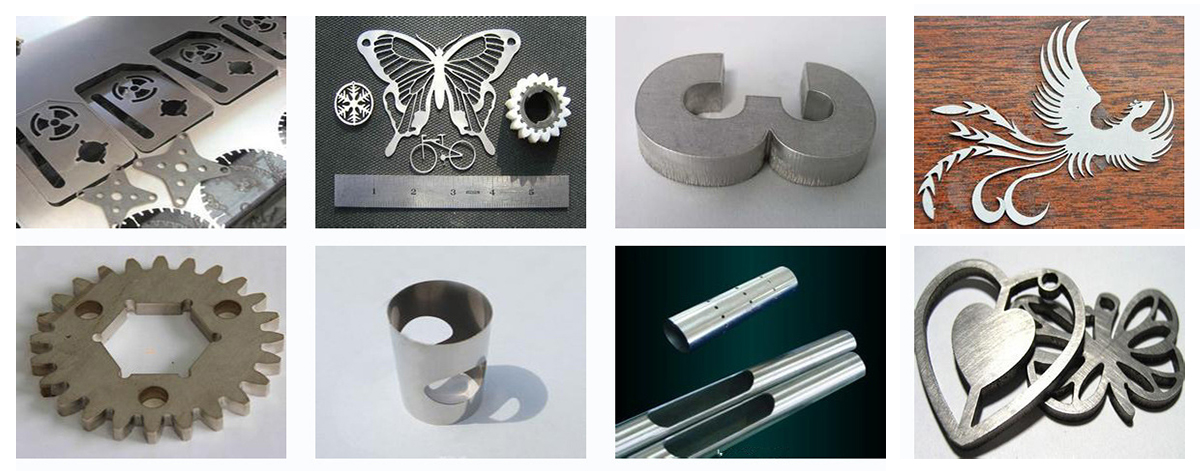

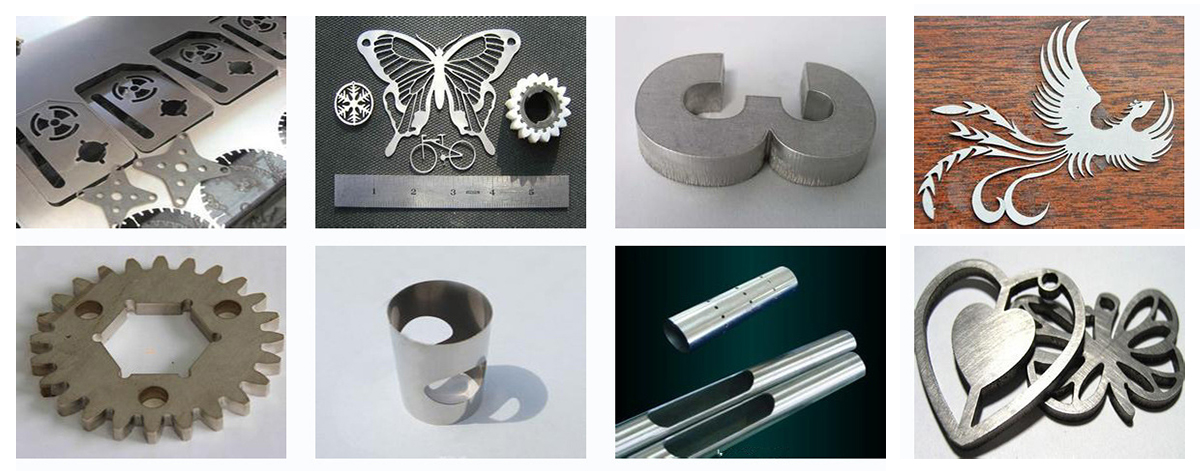

Laser cutting machine metal application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Widely used in sheet metal processing, aerospace, aviation, electronics, electrical, high-speed rail and subway parts, auto parts processing, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchenware, tool processing, decoration, advertising and other metal materials processing and manufacturing industries.

Parameters of laser cutting machine metal

Model | ST-FC3015R/ST-FC6015R/ST-FC6020R/ST-FC4020R |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (6000*1500mm, 6000*2000mm, 4000*2000mm) |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120meter/min |

Transmission system | Double rack & pinion and servo drive |

Tubes cutting capacity (standard) | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters |

Chuck type | Manual type or pneumatic self-centering chuck |

Maximum acceleration | 1.5G |

Power consumption | 6KW (based on laser power 1KW) |

Power supply | Three phase 380V/50Hz or 60Hz |

Machine weight | 7250Kg |

Overall size | 5050*2480*1830mm (L*W*H) |