| Working principle of CO2 laser marking machine

CO2 laser marking machine is a device that uses CO2 gas laser as a light source to mark, engrave or cut the surface of the workpiece through a laser beam. Its working principle mainly includes laser generation, beam transmission, focusing and control system.

Laser generation: The CO2 laser marking machine contains a CO2 gas laser. When the gas is electrified and excited, the molecular energy level of the gas transitions, and then a laser beam with a wavelength of 10.6um is generated.

Beam transmission: The laser beam is released from the laser, and after adjustment by the reflector and lens system, the quality and intensity of the laser beam are guaranteed, and then the laser beam is transmitted to the surface of the workpiece.

Laser focusing: The lens system focuses the laser beam to a very small focus, generating a light spot with high energy density, which has a thermal effect with the material on the surface of the workpiece, causing the material on the surface of the workpiece to evaporate or change color.

Control system: The output power of the laser, the movement trajectory and frequency of the laser beam and other parameters are controlled by a computer control system to achieve marking and engraving of different shapes.

CO2 laser marking machine uses CO2 gas laser to generate laser beam, focuses the laser beam onto the surface of the workpiece through the lens system for marking or engraving, and realizes precise processing operation through the control system. This equipment is widely used in the field of non-metallic material marking, with the advantages of high efficiency, precision and environmental protection.

| Characteristics of CO2 laser marking machine

CO2 laser marking machine has the following characteristics:

1. High precision: CO2 laser marking machine can achieve very fine marking and engraving, with excellent precision and resolution.

2. High speed: The laser marking speed is fast, and a large number of workpieces can be processed in a short time, improving production efficiency.

3. High clarity: The marking result of CO2 laser marking machine is clear and high in clarity, and it can achieve the marking of complex graphics and details.

4. Easy to operate: It is easy to operate, and the marking content can be flexibly adjusted through the computer control system, which is easy to learn and use.

5. Long-lasting marking: The marking effect of CO2 laser marking is long-lasting and durable, not easy to wear or fade, and is suitable for long-term retention of marking and identification needs.

6. Non-contact processing: Laser marking does not require contact with the surface of the workpiece, which reduces damage to the workpiece and is suitable for materials with high surface requirements.

7. Environmental protection and energy saving: The laser marking process does not require the use of chemical fluorescence, so no post-processing is required, no chemical pollution and waste are generated, and it meets environmental protection requirements.

CO2 laser marking machine has the characteristics of high precision, high speed, high clarity, easy operation, durability, non-contact processing, environmental protection and energy saving, so it is widely used in industrial production and manufacturing fields.

| Application fields of CO2 laser marking machine

CO2 laser marking machines are widely used in many fields, mainly including but not limited to the following aspects:

Industrial manufacturing

CO2 laser marking machines are widely used in industrial manufacturing to identify and track the production batch information of products and parts, anti-counterfeiting marks, etc., and are widely used in automobiles, electronics, machinery, aerospace and other fields.

Packaging industry

CO2 laser marking machines can mark packaging materials in the packaging industry, such as cartons, paper boxes, plastic bags and other products for tracking, tracing and anti-counterfeiting.

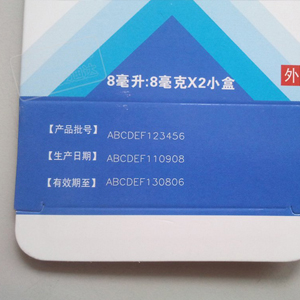

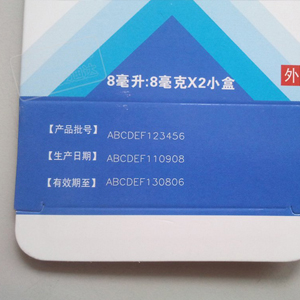

Pharmaceutical industry

Using CO2 laser marking technology on pharmaceutical packaging can help regulators and consumers trace the source of products and ensure the authenticity and safety of products.

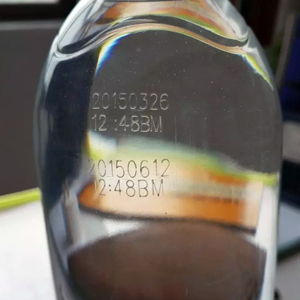

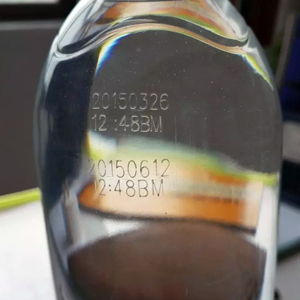

Food industry

Using CO2 laser marking machines on food packaging is often used to mark information such as production date, batch number, barcode, etc., to facilitate tracing the source of food and ensure food safety.

Leather processing

CO2 laser marking machines are widely used in the production of leather products, and can be used for personalized customized marking, engraving patterns, cutting and shaping, etc., to enhance the added value of products.

Woodworking industry

In the field of wood processing, CO2 laser marking machines can perform wood marking, engraving, cutting and other processes, and are used in furniture manufacturing, handicraft engraving and other aspects.

In general, CO2 laser marking machines are widely used in various fields of industrial production and manufacturing, with the advantages of high efficiency, precision and environmental protection, providing reliable solutions for product identification, decoration, processing, etc.