Product Parameters Samples Video

Features of gun engraving laser

1. Using high-quality light source, good spot quality, uniform optical power density, stable output optical power, and precise machining can be realized.

2. The built-in red light is used to preview the marking position, making it easier and more accurate to find the laser focus.

3. Adopt air-cooling technology, no need for water-cooling system support, stable performance and longer service life.

4. Humanized operation, long-term operation without failure, fully meet the needs of continuous industrial work.

5. The machine can increase the auto-focus function, which can adjust the height of the laser focus according to the products of different heights on the workbench.

6. Various auxiliary fixtures can be provided according to the actual needs of customers, such as rotating devices, 2D/3D worktables, pen-type turntables and other fixtures.

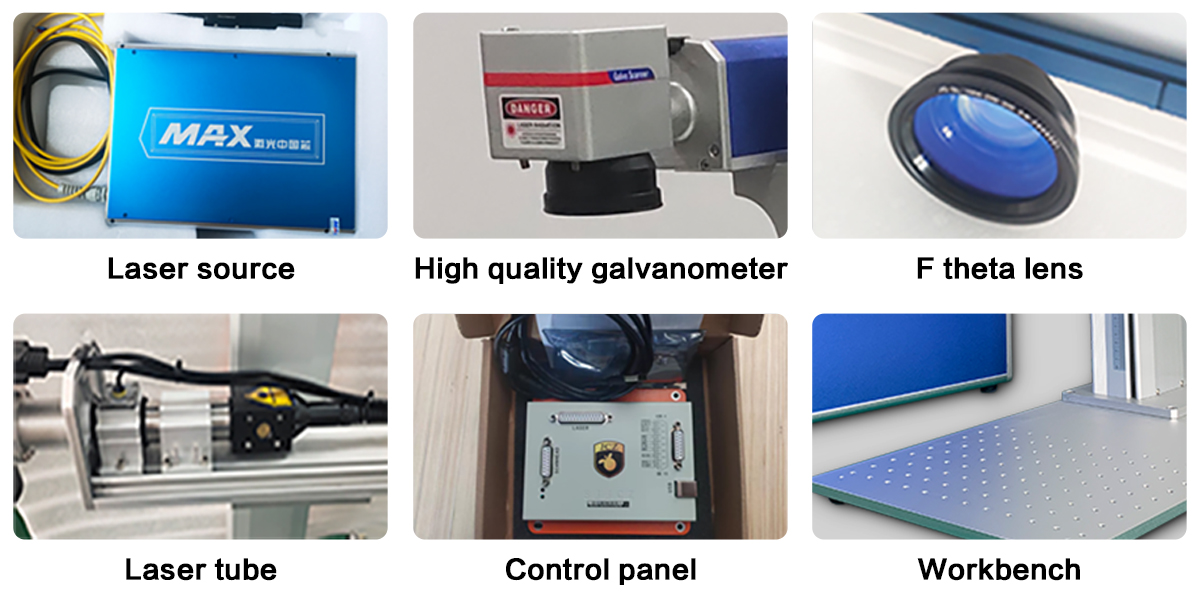

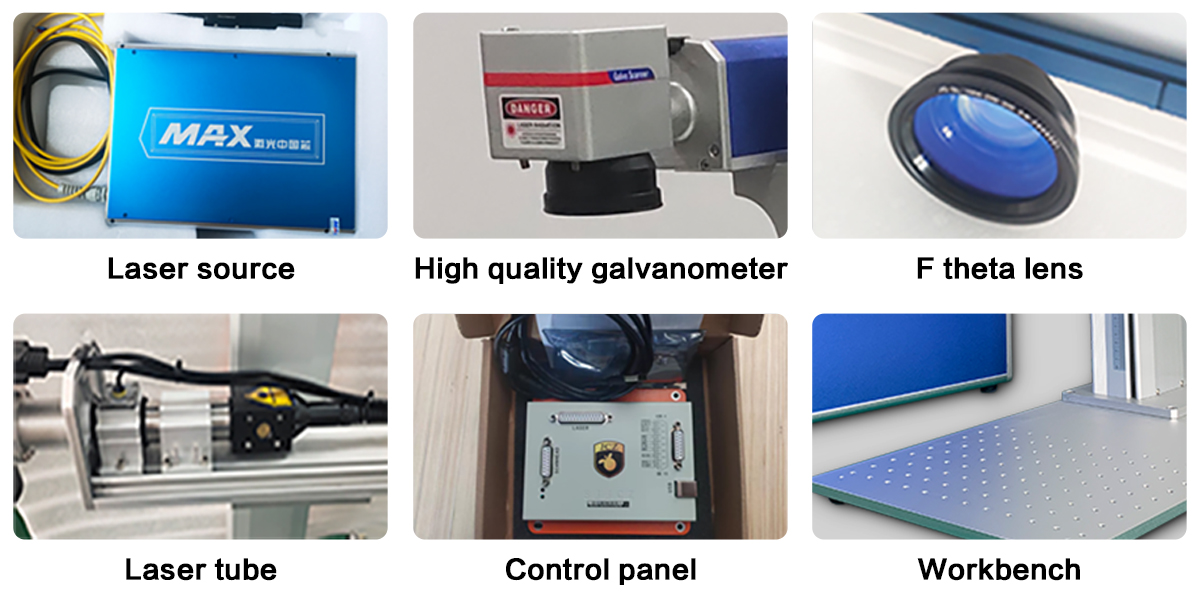

Details of gun engraving laser

1. Laser source

Using the famous brand Raycus, MAX, IPG and other fiber laser, spot quality, stable output power, service life of up to 100,000 hours, a wide range of power options.

2. High quality galvanometer

The high-speed digital galvanometer scanning head has good running stability and high positioning accuracy, which can realize high-speed marking and high precision.

3. F theta lens

Smart F theta lens, through which the fiber laser beam is focused to the workpiece surface, the energy is sufficient.

4. Control panel

Original EZCAD control system of the BJJCZ brand has high stability, fast data processing, high precision, and supports high-speed and high-precision marking functions.

Advantages of gun engraving laser

Gun Engraving Laser is an advanced manufacturing technology, through the laser beam on the surface of the gun fine engraving, can achieve personalized customization and precision processing, for the field of weapons manufacturing has brought about a revolutionary change.

1. High-precision customization

Laser engraving technology can realize micron-level fine processing on the surface of firearms, which can be personalized and customized according to users' needs to meet the needs of different users and improve the accuracy and practicality of firearms.

2. Strong durability

Laser engraved patterns and texts are not easy to wear, more durable than traditional printing or engraving methods, which can keep the appearance of firearms beautiful and clear, increasing the service life of firearms.

3. High production efficiency

Laser engraving technology can realize automated production, which improves production efficiency and manufacturing speed, reduces labor cost and production cycle, and makes firearms manufacturing more efficient.

4. Precise processing

Laser engraving technology can realize fine processing on the surface of firearms, such as engraving marks, patterns, etc., which ensures the accuracy and consistency of processing and improves the quality and performance of firearms.

5. Environmental protection and energy saving

The laser engraving process does not need to contact the physical surface, which reduces the use of chemical substances, reduces the generation of waste materials, meets the requirements of environmental protection, and saves energy and material costs.

6. Innovative design

Laser engraving technology provides more innovative possibilities for firearms designers to realize more complex patterns and structural designs, making the appearance of firearms more unique and fashionable and attracting more consumers.

Gun engraving laser application

Application materials

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry

Applicable to electronic components, hardware tools products, electrical products, consumer goods, sensors, auto parts, 3C electronics, handicrafts, precision instruments, gifts and ornaments, medical devices, high and low voltage electrical appliances, bathroom industry, battery industry, IT industry and other fields.

Parameters of gun engraving laser

Laser Power | 20W | 30W | 50W | 60W | 70W | 100W |

Model | ST-FL20P | ST-FL30P | ST-FL50P | ST-FL60P | ST-FL70P | ST-FL100P |

Max Marking Range | 110*110mm /150*150mm | 200*200mm | 300*300mm | 450*450mm | 450*450mm | 450*450mm |

Depth of Single Marking | 0.01mm | 0.03mm | 0.06mm | 0.07mm | 0.07mm | 0.1mm |

Same pattern marking efficiency | 10s | 7 s | 4s | 3s | 3s | 2s |

Whole Machine Power | 600W/h |

Laser Type | Fiber Laser |

Laser Source | MAX Brand (Raycus can choose) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Working Accuracy | ±0.002MM |

Marking Speed | 0-7000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 1064nm |

Minimum Font for Marking | 0.15mm |

Working Voltage | 220V±10%, 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC, PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 48KG |

Machine Dimension | 420*300*550mm (L*W*H) |