Details Product Parameters Samples Video

Features of tube laser welding

1. It adopts a fully enclosed optical path design, which has the advantages of dustproof and good sealing; it can work continuously for a long time (up to 24 hours).

2. The self-developed Wobble welding head is small and lightweight, easy to operate and flexible.

3. Has a variety of security alarm functions. The trigger switch is activated only when the soldering copper tip touches the metal and the safety clip clamps the metal plate. After the welding copper nozzle takes out the workpiece, the light will be automatically locked. The safety of the machine is very high, ensuring the absolute safety of the operator when working.

4. It is equipped with an original optical fiber cable with a length of 10 meters, thereby overcoming the limitations of the workbench space and enabling outdoor welding and long-distance welding.

5. Suntop's patented technology water circulation protection system and auxiliary gas detection effectively extends the life of the laser lens and prevents damage to optical components caused by Improper operation.

6. Infrared positioning verifies the position of the welding head and verifies the position during the welding process. The welding position is more accurate, the weld is smooth and beautiful, easy to grind and polish, and no post-weld treatment is required or only simple treatment is required.

Details of tube laser welding

1. Laser welding head

Light weight only 0.8KG, flexible and convenient to weld any shape of metal parts, adjustable welding seam width, can carry out 10 meters long distance welding. Equipped with safety temperature monitoring system.

2. Operation interface

Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group welding parameter library, light output cumulative timing, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, supporting stainless steel and aluminum wire of 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm diameter.

4. Laser Source

We use customized fiber with minimum core diameter of 20um for deeper penetration, laser life up to 100,000 hours, maintenance-free, with Bluetooth capability.

5. Water Cooler

Double circulation water cooling makes the laser source and weld head cooler, temperature control sensor adopts imported brand.

6. Welding connection fiber

10 meters long fiber optic cable built-in design, effectively avoid damage to the fiber and the problems caused by moisture, greatly improving the service life of the laser device.

Advantages of tube laser welding

1. The welding speed is fast, 5-10 times faster than traditional argon arc welding, and the processing cost can be reduced by about 30%.

2. The operation is simple and easy to learn, with no technical threshold required. Ordinary workers can operate it after short-term training and easily achieve high-quality welding results.

3. It is easy and flexible to use. The workstation can be adjusted at any time. There is no need to fix the workstation. It is free and flexible and suitable for welding in various working environment scenarios.

4. The welding range is wide, overcoming the limitation of workbench space, and enabling outdoor welding and long-distance welding.

5. A variety of welding methods can be used to achieve any angle welding, cladding welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc., and can be used for various workpieces with complex welds and large irregular-shaped workpieces. welding.

6. Concentrated energy, small heat-affected zone, no deformation, no blackening, large welding depth, fine and beautiful welds, firm welding, and the strength of the welds reaches or even exceeds the strength of the base material itself.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

Use of laser welding machine

With the continuous development of laser welding technology, laser welding machines are becoming more and more widely used.

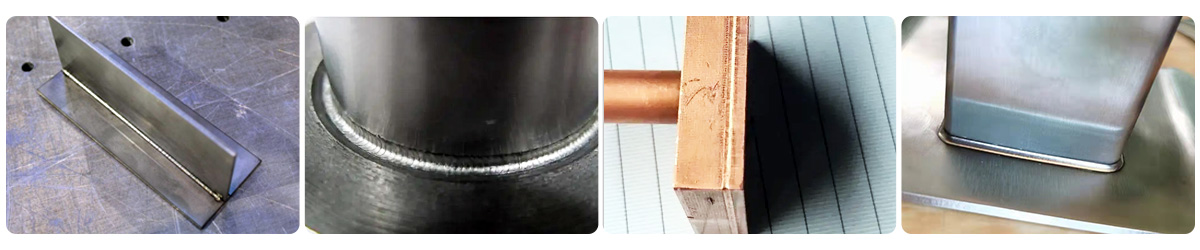

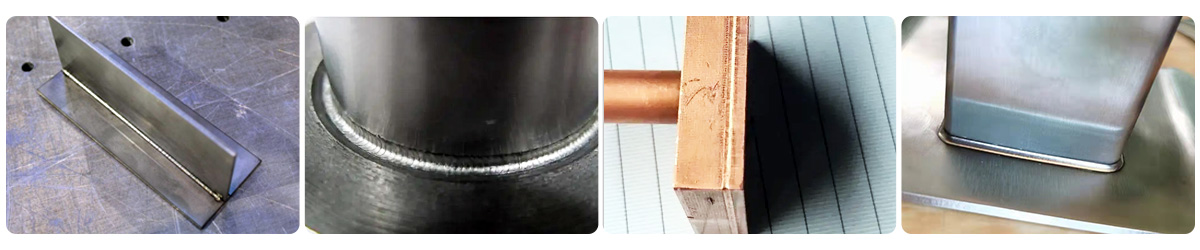

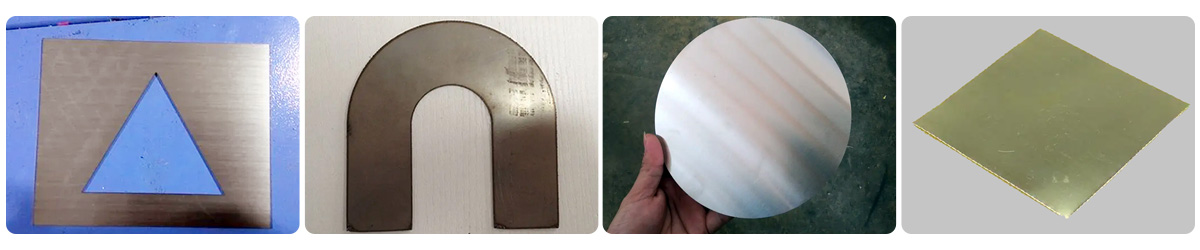

● Welding: The main welding objects of laser welding machines are metals, such as stainless steel, copper, aluminum, gold, silver, titanium, nickel, tin, chromium, niobium, carbon steel, mold steel, galvanized sheets, etc. It is suitable for flat, straight, Arc and arbitrary shape welding, welding work can be carried out from multiple angles to meet users' personalized welding needs.

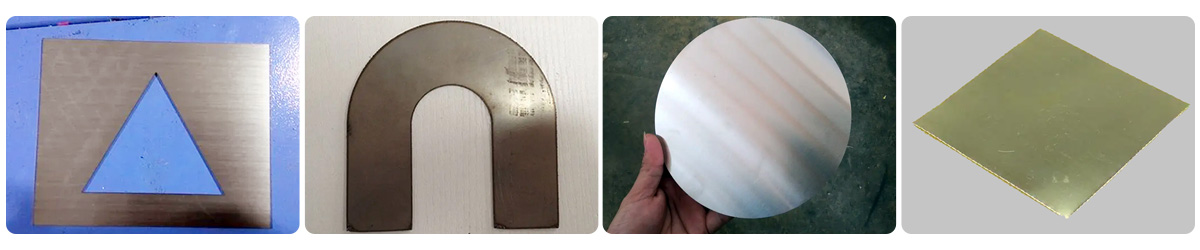

● Cutting: Welding and cutting are often inseparable. Laser welding machines combine the functions of the two. Laser welding machines can be used to laser cut metal materials, such as copper plates, aluminum plates, stainless steel plates, carbon steel plates, galvanized plates, etc. Meet the cutting needs of conventional thin plates.

● Cleaning: Cleaning with a laser welding machine is easy and flexible, and can remove rust, oxides, grease, dirt, etc. on the surface of various workpieces. When using a handheld laser welding machine for cleaning, it is necessary to avoid harm to the human body caused by the laser beam.

● Weld bead cleaning: It can effectively remove oxides, welding slag, oil, dust and other impurities produced during the welding process, making the weld surface clean. This not only helps improve the quality of the weld, but also enhances its strength and appearance. Laser cleaning is highly precise and controllable, thoroughly cleaning the weld surface without damaging the base material.

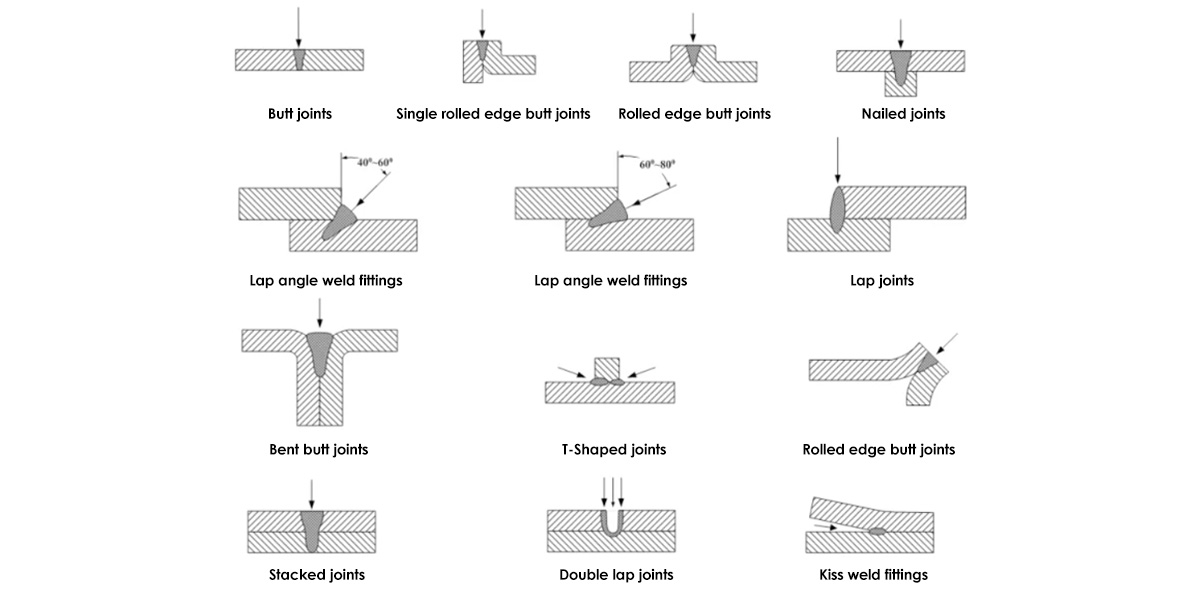

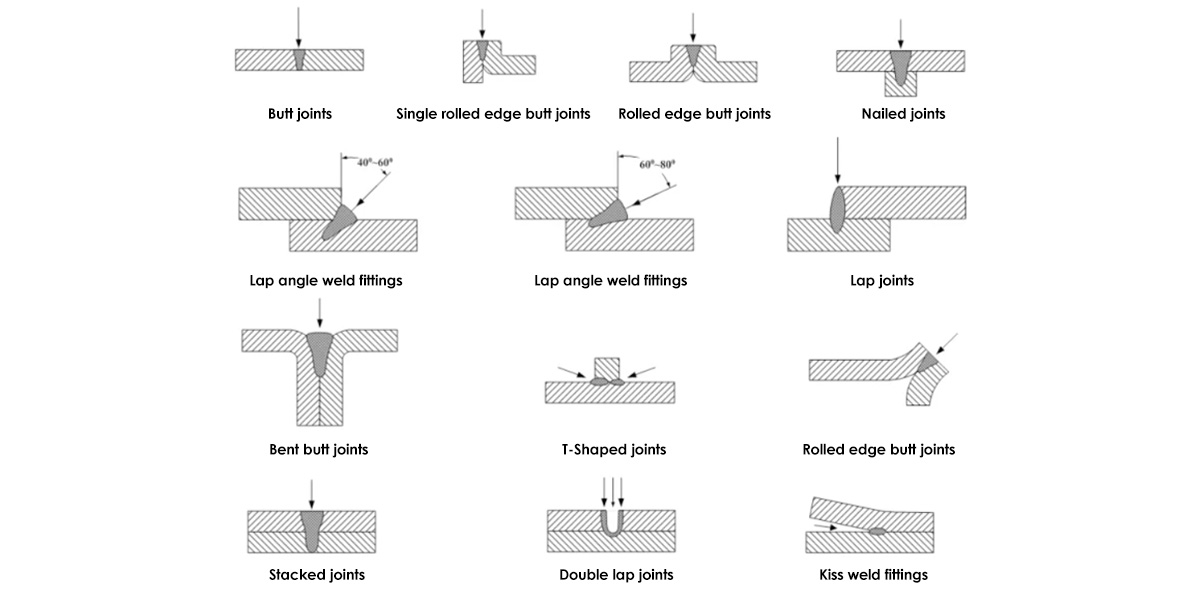

Welding method

There are various welding methods to choose from, allowing for welding at any angle, including overlay welding, butt welding, vertical welding, fillet welding, inside corner welding, outside corner welding, etc. These methods can be used for welding various workpieces, including complex welds and irregularly shaped workpieces, especially larger ones.

Application materials

Suitable for stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various weldings between different materials, such as copper-brass, titanium-molybdenum, titanium-gold, nickel-copper, etc.

Application industry

Widely used in auto parts, shipbuilding industry, aerospace, 3C electronics, precision parts, molds, high-end machine tools, military equipment, hardware manufacturing, kitchen and bathroom, home appliances, motor accessories, bellows, batteries, solar energy, optical communication shells and other industries Application areas.

Parameters of tube laser welding

Model | ST-FW1500H | ST-FW2000H | ST-FW300H |

Power | 1500W | 2000W | 3000W |

Welding gun weight | 0.8 | 0.8 | 0.75 |

Max. welding thickness (mm) | ≤3 | ≤5 | ≤8 |

Max. welding seam width (mm) | 5 | 5 | 8 |

Laser type | Fiber laser (Suntop custom 20um welding exclusive) |

Laser detection method | Bluetooth wireless connection, Mobile App Monitoring |

Control panel language support | English, Spanish, German, French, Turkish, Italian, Russian, Vietnamese, Thai, Korean, Japanese, etc. |

Laser wavelength (nm) | 1064+5 |

Suitable welding materials | Carbon steel, stainless steel, aluminum, galvanized sheet metal, brass, iron and other metal materials |

Adapted welding methods | Spot welding, overlap welding, splice welding, fillet welding, lap welding etc. |

Laser power adjustment range (%) | 10-100 |

Cooling method | Advanced water-cooling, dual temperature control and automatic control |

Welding aiming preview method | Built-in Red-Light pointer |

Protection systems | Air pressure sensor and solenoid valve control |

Length of fiber optic cable (meter) | Standard 10 (can be customized 15) |

Welding shielding gas | Argon or nitrogen (air pressure approx. 6-8 bar) |

Working environment | Temperature 5-45 °C /humidity 10-90% |

Other optional support functions | Cleaning + cutting | Cleaning + cutting | Cleaning + cutting + weld bead cleaning |

Max. Cutting thickness (mm) | 1.2 | 1.5 | 2 |

Max. cleaning width (mm) | 40 | 40 | 120 |

Automatic wire feeder type (Universal with TIG wire) | Single wire feed | Single wire feed | Support both the double wire feed and single wire feed |

Solid wire type (SS, Iron, AL, Brass) | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6 | 0.8, 1.0, 1.2, 1.6, 2.0, 2.5 |

Temperature control monitoring alarm | Yes | Yes | Yes |

Main machine consumables | Laser protective lenes, welding nozzles, welding wires |

Machine size (MM) | 686*425*611 | 750*1080*1000 | 750*1080*1000 |

Machine net weight (KG) | 110 | 220 | 240 |

Power supply requirement | 110V / 220V±10%, single phase | 380V±10%, three phase |

Total power consumption (Maximum) | 3500W | 4500W | 7000W |