Product Details Product Parameters Samples Video

Automatic loading and unloading system mainly include the follow items

This system includes automatic feeding and automatic unloading. The automatic feeding system is seamlessly connected with the laser pipe cutting machine through the numerical control system to realize the hoisting and feeding of the whole bundel of pipe materials. The control system sets up the intelligent material division of the pipe and the whole conveying process is full automatic, which saves the cost of the manual feeding and greatly improves the working efficiency of the laser pipe cutting.

1, Raw material rack: the maximum loading bearing capacity of PVC strip is 3 Tons.

2, Fixed pipe attitude structure: ensure each time the pipe imput on the conveyor belt direction, servo motor control to determine the size of the pipes.

3, transition sproket: used for conveying metal pipes.

4, Conveyor chain: this device for placing multiple pipes, which can be placed in a predetermined position.

5, Feeding jacking mechanish: adjust the center heigh of the feeding pipe to keep the same as the center height of pipe cutting device.

6, Pipe length fixing mechanish: through the servo motor to push the pipe, determine the actual size of the pipes.

7, pipe push mechanish: servo motor positioning, fast and accurate pipe to the cutting machine.

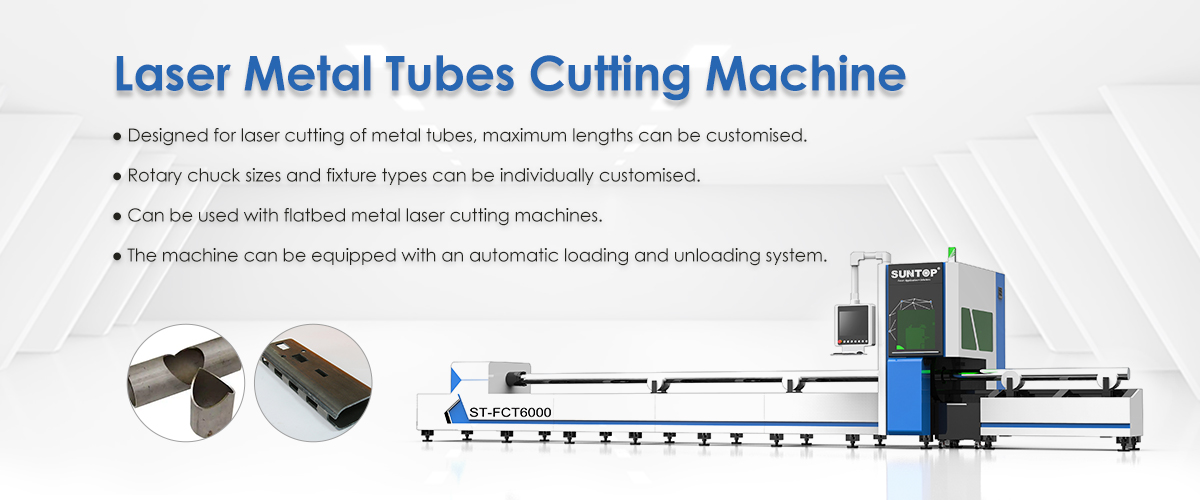

Laser pipe cutting machine the application materials

Suitable for steel tubes, carbon steel, stainless steel, alloy steel, aluminium, copper, titanium, etc., good pipe cutting effect for all kinds of alloy materials with high hardness and easy brittleness (depending on the actual power o the machine.

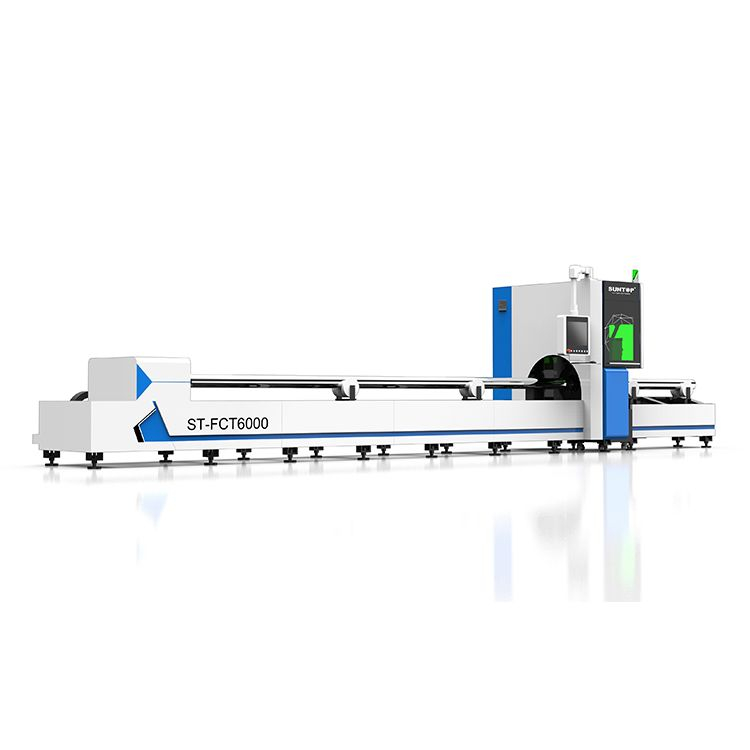

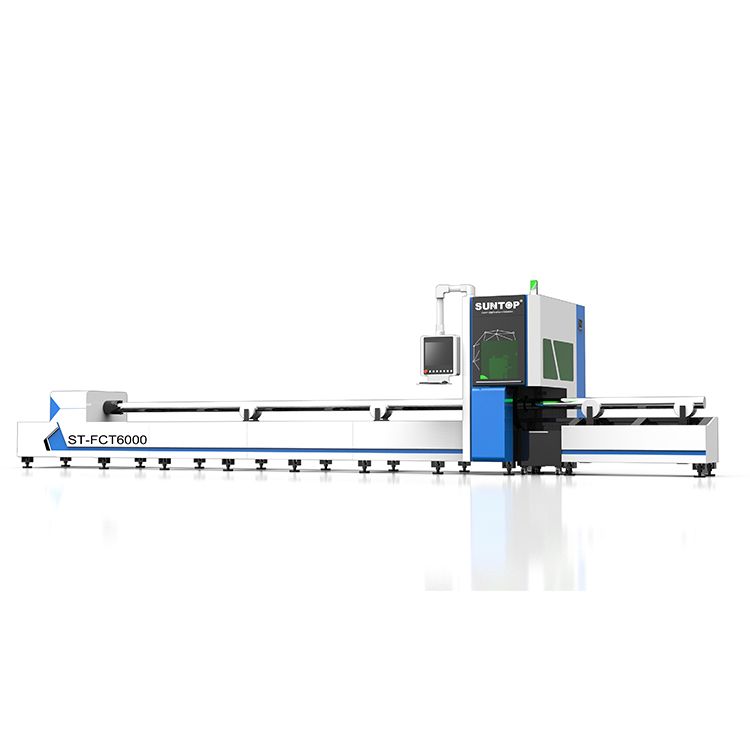

Laser pipe cutting machine's main advantages:

1, high precision: it's suitable for cutting pipe and all kinds of craft word and patterns.

2, Fast cutting speed: the laser cutting is more than 100 times the speed of linear cutting machine.

3, laser pipe cutting with small thermal impact, not easy to deformantion, flat and beautiful cutting surface, no need for secondary treatment.

4, High cost performance: the machine price is only one third of the same performance CO2 laser cutting machine, and the same efficiency of the CNC punching machine two-fifths.

5, Laser cutting use cost is very low, almost no consumables, maintenance free, laser generator lifetime up to 100,000 hours.

6, No need to make the mold, only need to make the drawing from computer, the final product can be cut out immediantely, which can quickly develop new products, and can greatly save costs.

7, The machine has an automatic tracking system, which can not only cut the plane surface, but also can cut all kinds of uneven surface.