Advantages of ultra-high precision small fiber laser cutter

1. Utilize the renowned Swiss brand Raytools laser cutting head, which is equipped with a dynamic automatic focusing system. This system ensures that the metal sheet and the laser head maintain a consistent distance, resulting in precise cutting effects.

2. The well-known Japanese servo motor works in conjunction with the double ball screw drive system, providing a higher level of cutting precision compared to a single drive system.

3. Incorporating the globally recognized fiber laser Raycus, the cutting speed can reach up to 15M/min.

4. The NC Studio control system is installed, catering to various cutting requirements.

5. The fiber laser cutting machine is equipped with a red light indicator and pre-run function, guaranteeing the accurate identification of the cutting position.

6. The lower part of the machine is equipped with a chip car, which can collect the waste and small parts in the production process, and is equipped with smoke and dust vent.

7. Easy to operate, CAD graphics can be imported for processing, cutting data can be saved.

8. The machine features an automatic oil filling function, with each magnetic strip having an oil pipe. By activating the oil filling switch, the machine will automatically lubricate itself, requiring oil filling every two months.

9. The design of the protective cover is both environmentally friendly and aesthetically pleasing. The green glass cover window filters the laser beam, ensuring it is harmless to the eyes.

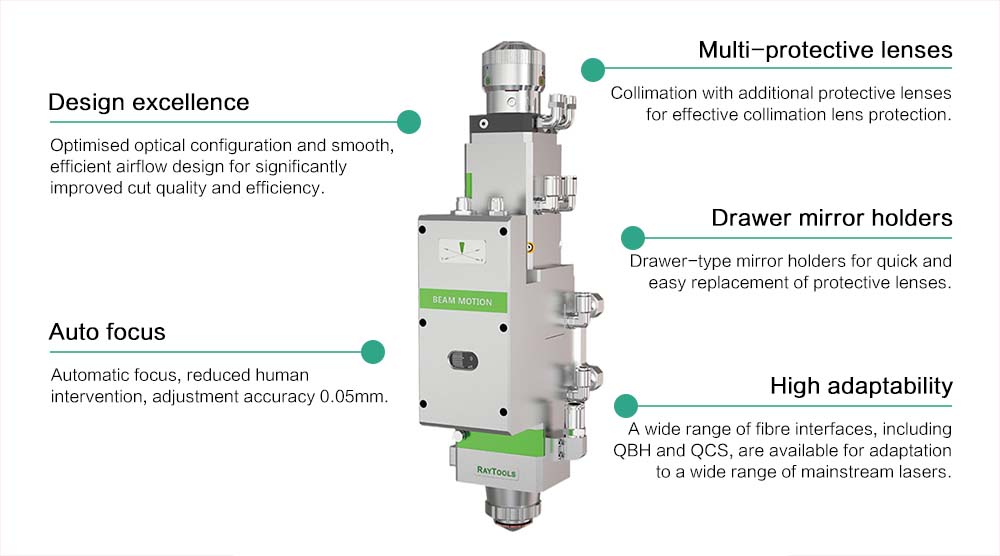

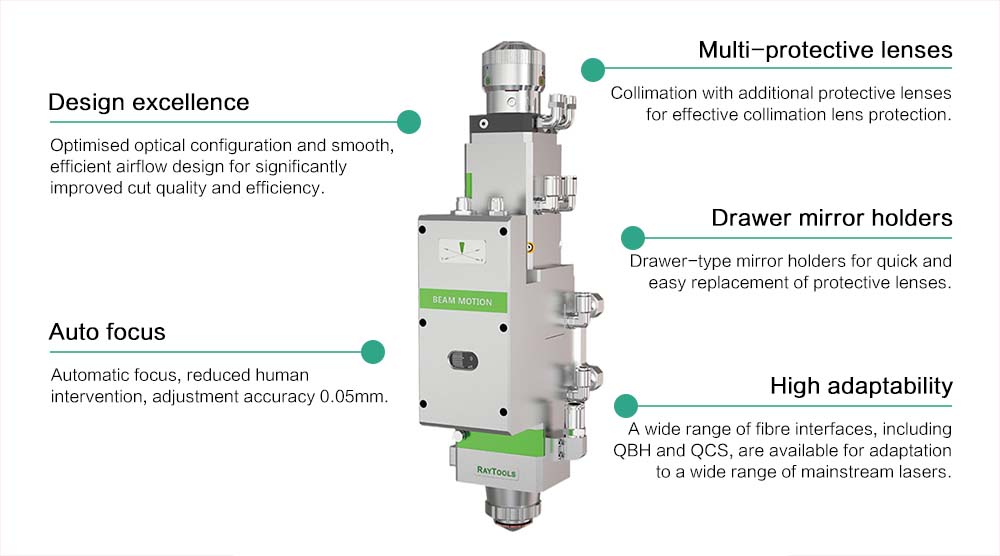

Laser cutting head

1, It is equipped with a special cutting head for optical fiber laser and a capacitive non-contact automatic tracking system, which can adjust the focal length to ensure the best cutting effect of the whole plate and avoid scrapping caused by the change of focal length when the material is uneven;

2, The focal length of the focusing mirror: f=120mm, using coaxial blowing cutting, to ensure the cutting quality;

3, The focusing mirror barrel and cutting head have the functions of automatic calibration and autofocus, so that users can adjust and replace different materials and plates of different thickness at any time, which greatly improves the working efficiency;

4, The cutting head contains protective lens to reduce the consumption of expensive consumables such as reflector and focusing lens;

5, As the cutting head is equipped with non-contact sensing device, under the control of the system, the stable z-axis floating function can be realized, which directly eliminates the impact of uneven plates on the cutting quality;

6, The cutting head adopts flexible design, with fast anti-collision protection function and flexible automatic reset function, which can automatically stop cutting and flexibly deviate and reset when accidental collision occurs, and can automatically return to the original cutting point when cutting continues, so that the whole cutting work is not affected.

Laser indicating system

The fiber laser cutting machine is equipped with a laser indicating system (red light indicating) to help the operator calibrate the laser cutting head at any position on the plate. Semiconductor red light wavelength (638nm).

Slag discharge system

The bottom of the bed is equipped with a chip cart, which can collect the waste and small parts in the production process.