Before you can understand how to operate a laser welding machine, you need to understand what functions a laser welding machine has and in what scenarios it can be used.

The use of laser welding machine

With the continuous development of laser welding technology, the uses of laser welding machines are becoming more and more extensive.

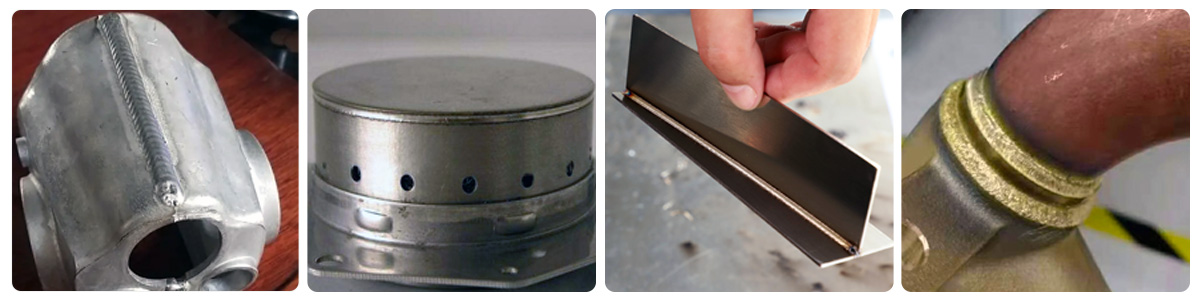

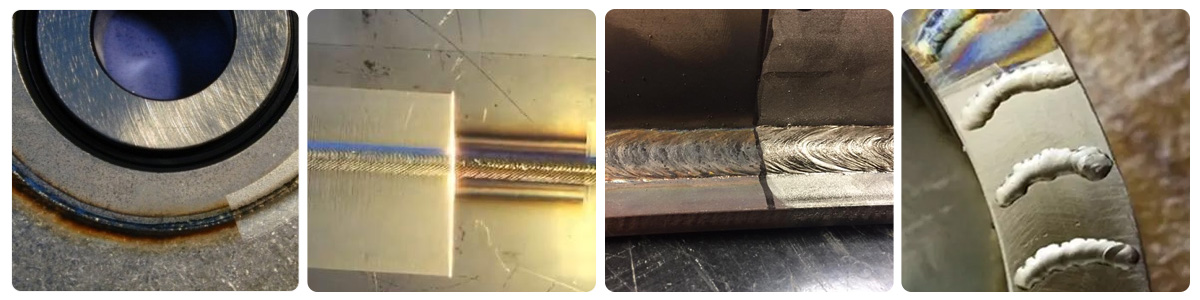

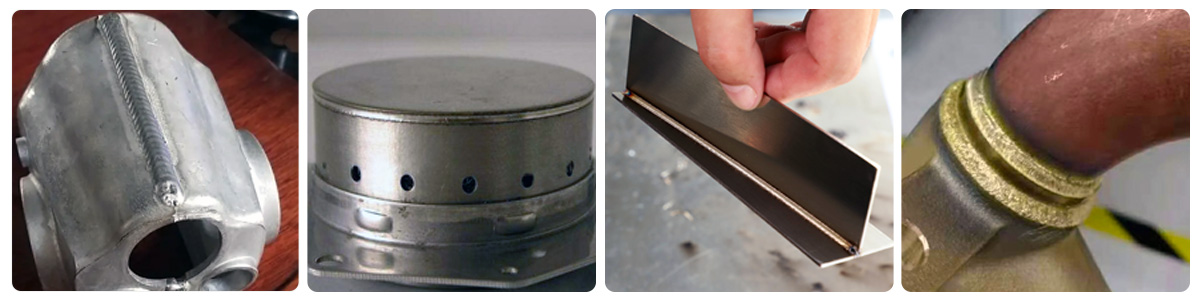

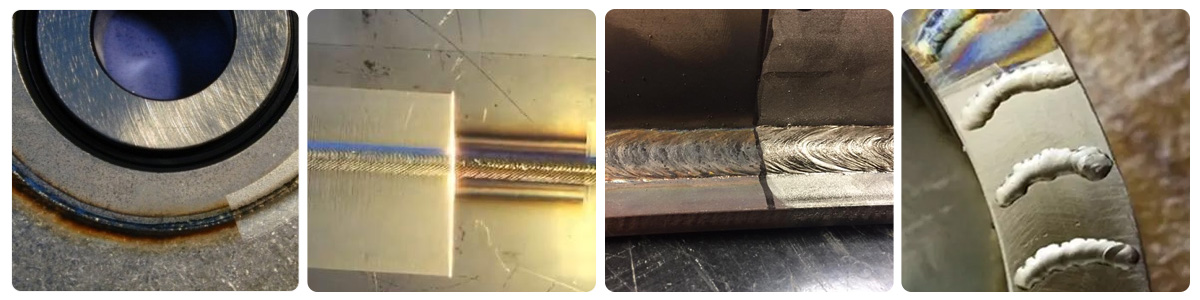

1. Welding: laser welding machine main welding object for the metal, such as stainless steel, copper, aluminum, gold, silver, titanium, nickel, tin, chromium, niobium, carbon steel, die steel, galvanized sheet, etc., suitable for plane, straight line, arc and any shape of the welding, multi-angle welding work to meet the user's individual welding needs.

2. Cutting: welding and cutting are often inseparable, laser welding machine will combine the functions of the two together, laser welding machine can be used for laser cutting of metal materials, such as copper, aluminum, stainless steel, carbon steel, galvanized plate, etc., to meet the conventional thin plate cutting needs.

3. Cleaning: By replacing the laser nozzle and cleaning lens, the material surface cleaning function can be realized, effectively removing rust spots, oxidized layer, oil, etc. on the material surface without destroying the surface characteristics. With the characteristics of non-contact, do not need cleaning fluid, can replace the professional cleaning equipment.

4. Weld channel cleaning: can effectively remove the welding process generated by the oxides, welding slag, oil, dust and other impurities, so that the weld surface becomes clean. This not only helps to improve the quality of the weld, but also enhances the strength and appearance of the weld. Laser cleaning is highly accurate and controllable, allowing the weld surface to be thoroughly cleaned without damaging the base metal.

Laser welding machine operation

Laser welding machine safe operation is very important, can not be separated from the operating specifications, if not in accordance with the operating steps, may not be able to start or even damage the machine normally.

First, check the work

1. Check the supporting facilities, such as power lines, water circulation, argon gas, etc. are accessed and can be used normally.

2. Check the machine equipment to see if the surface and above are clean and free of debris piled up.

Second, start welding

1. Turn on the power, start the laser welding machine, turn on the laser.

2. Set the parameters, the workpiece material is not the same as the parameters needed to make a difference, according to the site conditions set reasonable parameters, the first test welding, if the welding effect is not ideal can be adjusted again parameters. 3, formal welding, the workpiece will be welded, the workpiece will be welded, the workpiece will be welded.

3. Formal welding, the workpiece placed on the welding table, adjust the welding position and angle, and control the welding speed. 4, operation according to the workpiece material, the parameters are different.

4. Decide whether to add welding wire or not according to the actual situation of the workpiece during operation.

5. After the welding is completed, check the welding seam to ensure the welding effect of the workpiece.

Third, shut down the equipment

After welding is completed, exit the program, close the laser, argon valve and power switch.

In addition, the operator in the welding process should pay attention to their own safety as well as the safety of the surrounding personnel, before using the laser welding machine, wear protective equipment, such as welding cap, gloves, etc., to protect the skin and eyes, welding laser beam do not shoot directly at other people, and to ensure that other people away from the laser beam.