The basic principle of laser welding technology is to use a high-energy-density laser beam to heat the surface of the workpiece, melt it instantly and form a weld. During the laser welding process, after the laser beam is focused by the optical system, it can accurately focus high energy on the welding area, quickly melt the metal, and form a uniform and fine weld during the solidification process through surface tension. Laser welding has the advantages of small heat input, fast welding speed, small deformation, shallow melting depth and easy control.

The application value of Portable Laser Welder in industrial manufacturing is mainly reflected in the following aspects:

● High efficiency and precision: The laser welding machine has a high-energy-density laser beam, which can achieve rapid heating and high-speed welding, and improve production efficiency. At the same time, laser welding has high welding accuracy, which can achieve fine welding of complex workpieces and ensure welding quality.

● Small deformation and small heat-affected zone: The laser welding machine has a fast welding speed and concentrated heat input, which can effectively reduce the deformation and heat-affected zone of the workpiece. It is suitable for fields with high requirements for workpiece deformation, such as precision instrument manufacturing.

● Automated and flexible production: Laser welding machines can be used in combination with automated equipment such as robots to realize automated welding production lines, improve production efficiency, reduce manual intervention, and are suitable for large-scale industrial manufacturing.

● Wide application: Laser welding machines can weld a variety of metal materials and have a wide range of applications. They are suitable for multiple industries such as automobile manufacturing, aerospace, and electronic equipment manufacturing.

Laser welding technology has a wide range of application value in the field of industrial manufacturing with its high efficiency, high precision, low deformation, and applicability to a variety of materials. It has brought obvious advantages and value in improving production efficiency, optimizing product quality, and reducing production costs.

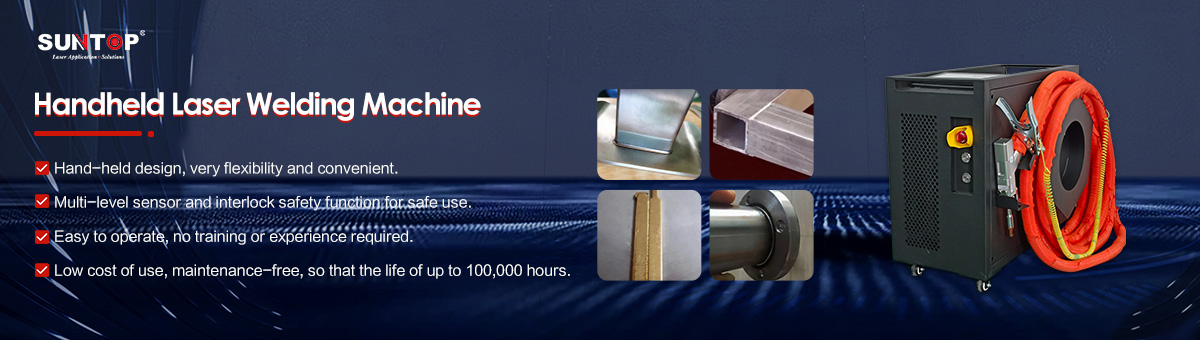

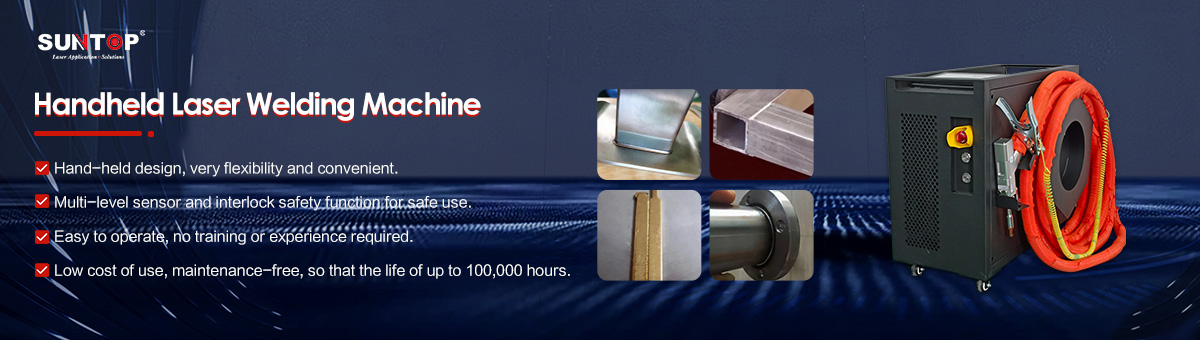

Why Choose Portable Laser Welder?

1. Portability: The primary advantage of a portable laser welder is its mobility. Being lightweight and compact, it can be easily moved to different work areas or job sites as needed. This flexibility allows for on-site repairs or welding tasks, reducing the need to transport heavy or bulky equipment.

2. Versatility: Portable laser welders are versatile tools that can be used for a wide range of applications across various industries. They can weld different types of metals, including stainless steel, aluminum, and titanium. This versatility makes them suitable for a variety of welding projects.

3. Precision and Accuracy: Laser welding technology offers high precision and accuracy in welding joints. The focused laser beam can create narrow, deep welds with minimal heat-affected zones, resulting in strong and precise welds. This level of precision ensures consistent quality and reduces the need for additional post-welding processing.

4. Efficiency and Cost-effectiveness: Portable laser welders are known for their high welding speed and efficiency. They can deliver fast welding speeds while maintaining quality and precision, leading to increased productivity and reduced labor costs. Additionally, the minimal material distortion and low heat input associated with laser welding can help save on material costs and reduce waste.

5. User-Friendly Operation: Portable laser welders are designed for ease of use, with user-friendly interfaces and controls that simplify the welding process. Operators can quickly set up and adjust welding parameters, making it convenient for both experienced welders and beginners to use the equipment effectively.

In conclusion, choosing a portable laser welder offers the advantages of portability, versatility, precision, efficiency, and user-friendly operation. These benefits make portable laser welders a valuable tool for various welding applications, providing high-quality welds, increased productivity, and cost savings.

Comparison between laser welding and traditional welding

1. Accuracy comparison

Laser welding uses high-energy laser beams for welding, and the weld seam has high precision, which is suitable for projects with high welding precision requirements. Traditional welding requires molten metal to fill the weld, and the precision is relatively low.

2. Speed comparison

Laser welding is fast, generally 5-10 times faster than traditional welding. This makes laser welding have obvious advantages in mass production projects.

3. Heat effect comparison

Laser welding has a small heat-affected zone and small thermal deformation of the workpiece, which is suitable for materials sensitive to heat. Traditional welding has a large thermal effect and is prone to deformation and residual stress.

4. Automation comparison

Laser welding can be highly automated, and can realize a fully automatic welding production line with equipment such as robots. Traditional welding requires manual operation by the operator, and the degree of automation is low.

5. Energy consumption comparison

Laser welding has low energy consumption, high efficiency, and energy saving. Traditional welding requires relatively high energy consumption.

6. Cost comparison

The equipment and energy costs of laser welding are generally high, but due to the fast welding speed, it can save labor costs and production time in mass production. Traditional welding equipment and costs are relatively low, but may incur high labor costs and time costs in large-scale production.

7. Environmental friendliness

Laser welding usually produces less waste and welding fumes, and has less impact on the environment. Traditional welding may produce a lot of waste and exhaust gas

|

Single Side Weld Thickness

Maximum melting | 1500W | 2000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 |

Mild steel (mm) | 0.5-4 | 0.5-6 |

Aluminum (mm) | 0.5-3 | 0.5-4 |

Brass/copper (mm) | 0.5-1.5 | 0.5-2 |

Galvanized sheet (mm) | 0.5-3 | 0.5-4 |

Iron (mm) | 0.5-4 | 0.5-6 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times

|

Application Materials

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

|

Application Industry

Widely used in all kinds of sheet metal, molds, chassis, power distribution cabinets, kitchen and bathroom products, all kinds of hardware lighting, advertising signs, door and window frames, handicrafts, household products, food machinery, medical equipment, auto parts and other industries.

|

Product Specification

Model | ST-FW1500H | ST-FW2000H |

Power | 1500W | 2000W |

Beam quality | ≤1.2 M⊃2; | ≤1.3 M⊃2; |

Laser wavelength | 1080nm |

Light exit mode | QCW /PWM /CW |

Max modulation frequency | 1000HZ |

Output power stability | <3% |

Aiming positioning system | Built-in Red Light |

Terminal type | QBH |

Delivery cable length | 10M (can be customized) |

Power supply | AC220V±10%, 50/60Hz |

Cooling system | Built-in air cooling |

working environment | Temperature 5-45°C /humidity 10-90% |

Applicable material | Almost all metal materials such as carbon steel, stainless steel, aluminum, brass and galvanized sheet. |

Net weight/gross weight | 35KG/46KG |

Machine size | 276*667*542mm |

| Product Samples

| Product Videos