Details Product Parameters Samples Video

4-in-1 Function of Handheld Laser Welding Machine

1. Welding

The main purpose of the laser welding machine is undoubtedly welding, welding almost all the metal materials, in a variety of complex environments can be well completed welding, high productivity, than the traditional argon arc welding, welding and other processes have more obvious advantages. Welding, high productivity, more obvious advantages than the traditional argon arc welding, electric welding and other processes.

With the laser welding machine, the weld width is small, the depth is large, the thermal shock area is small, the deformation is small, the weld is flat and beautiful, the welding quality is high, no porosity, can be precisely controlled, the welding quality is stable, and there is no need to deal with it after welding or it can be simply dealt with.

2. Cutting

Welding and cutting are often inseparable, laser welding machine combines the functions of the two together, laser welding machine can cut the thickness of 2 mm metal, such as copper, aluminum, stainless steel plate.

Welding and cutting can be freely switched, just change the welding copper nozzle to cutting copper nozzle, very convenient.

3. Cleaning

The use of laser welding machine for cleaning easy to use and flexible, able to remove all types of workpiece surface rust, oxides and grease and dirt, etc., with no contact characteristics, do not need cleaning fluid, the maximum cleaning width of up to 120mm, can replace the professional cleaning equipment.

4. Weld bead cleaning

It can effectively remove oxides, welding slag, oil, dust and other impurities generated during the welding process, making the surface of the weld clean. This not only helps to improve the quality of the weld, but also enhances the strength and appearance of the weld.

Laser cleaning is highly accurate and controllable, and thoroughly cleans the weld surface without damaging the base metal.

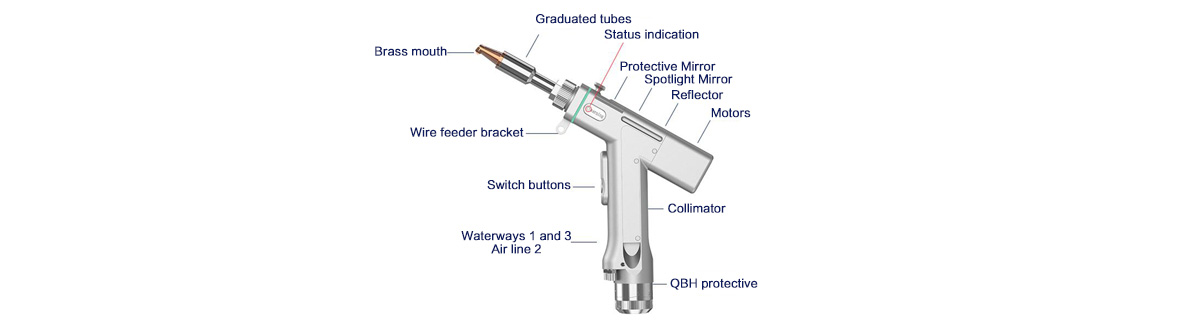

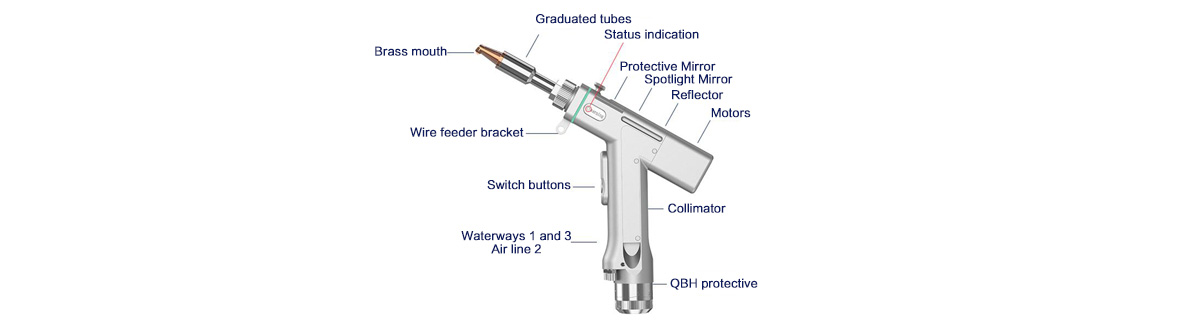

Self-developed Wobble Welding Head

| Basic features of the product | Self-developed control system and structural design, to adapt to a variety of welding needs within 3000W, set up a number of safety alarms and status indicators, the abnormal state of instantaneous response. Net weight 0.75kg, flexible operation, easy to use. |

| More stable machine | All parameters are visible, real-time monitoring of the machine status, avoiding problems in advance, convenient for troubleshooting and solving, ensuring the stable work of the handheld welding head. |

| Subvert the structural design | The main structure of the one-piece design and processing, greatly reducing the failure rate, and at the same time, convenient for later maintenance.

|

| Controllable parameters and high repeatability | Stable nozzle air pressure and lens state, only the laser power is stable, the process parameters must be repeatable, saving time for machine adjustment and improving work efficiency. |

User-Friendly of Operation Interface

● Advanced resistive touch screen with higher sensitivity, intelligent control.

● Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group library of welding parameters and cumulative timing of light output etc.

● Support multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

Auto Welding Wire Feeder System (single/double feeder optional)

● Depending on the actual welding requirements, the double wire feed increases the width of the weld seam to a maximum of 8 mm and enables a high stacking effect to be achieved for thicker sheet metal.

● Touch screen design, Automatic wire filler, fully digital design, supports 0.8mm, 1.0mm, 1.2mm, 1.6mm and 2.0mm diameter stainless steel and aluminum wires.

● 220V power supply drive, more powerful wire feeding, no wire jamming, more uniform welding quality results.

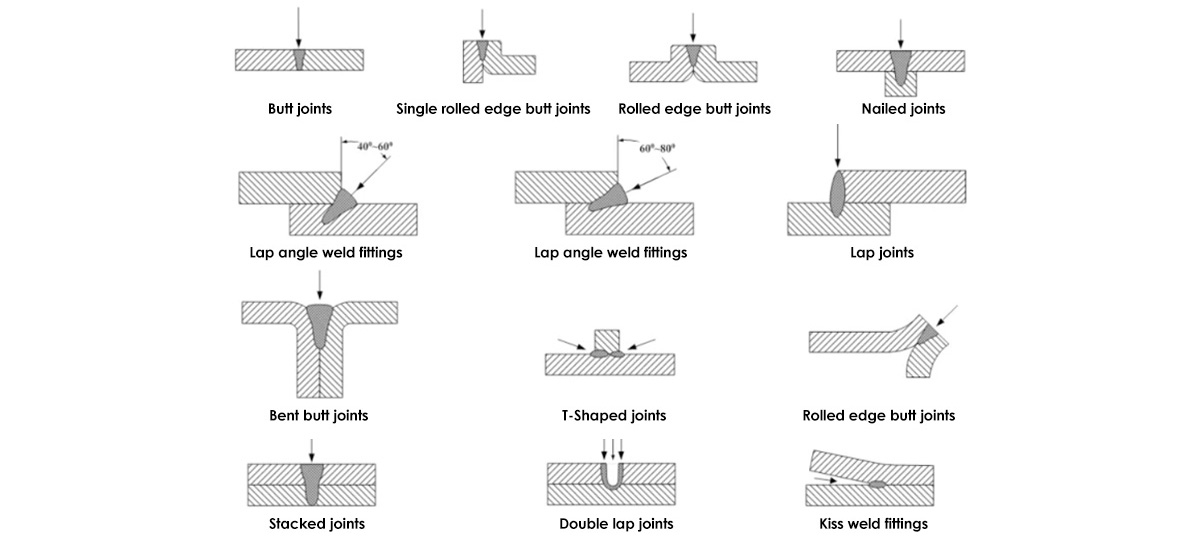

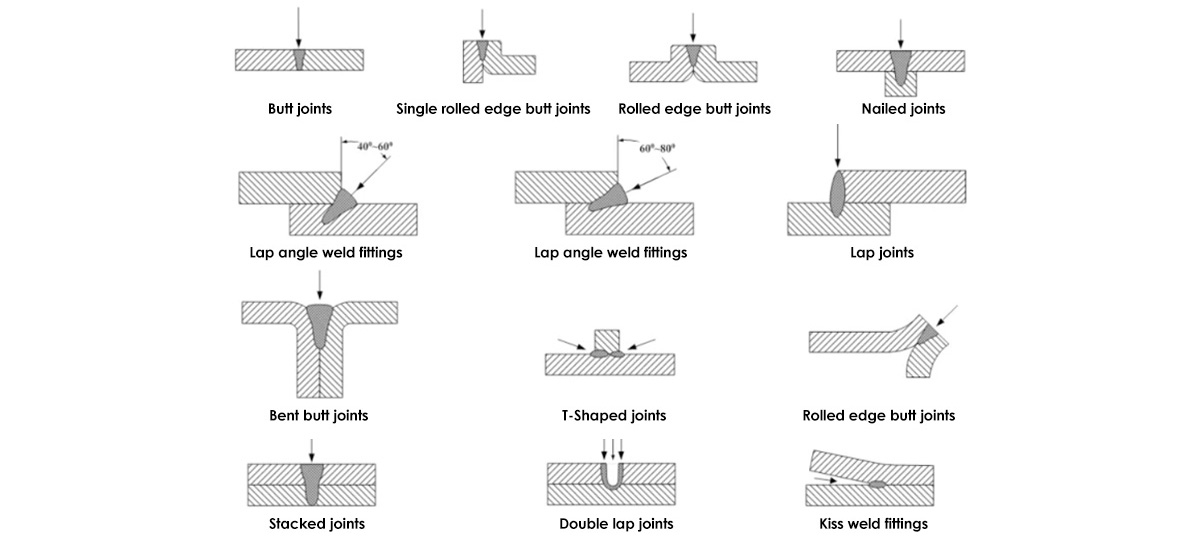

Welding Method of Handheld Laser Welding Machine

It can realize welding at any angle, such as stack welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc. It can weld all kinds of workpieces with complex weld seams and non-regular shapes of larger workpieces.

Safety features of Handheld Laser Welding Machine

ST-FW1500H/2000H/3000H is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

● Key switch control of laser source and Emergency-stop button ensure deliberate operation.

● Fiber laser interlock verifies integrity of laser delivery to the welding gun.

● Laser weld gun trigger, enable and then fire, for intentional operation.

● Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts.

Cooling Fan and Temperature Sensor

Added cooling fan and temperature sensor, when the temperature reaches the set temperature, the cooling fan will automatically turn on.

Advantages of Handheld Laser Welding Machine

● High speed: Up to 4X Faster than traditional methods-increased productivity for lower costs-per-part.

● High quality: Consistent welding of thick, thin and reflective metals without distortion, undercut or burn through - minimal heat affected zone.

● Easy to use: No need training, simple setup, easy to learn and operate, consistent high quality welding.

● Wobble welding: Up to 8mm additional weld width - increases capacity and creates highly aesthetic seams.

● Operator safety: Multi-level sensors and interlock safety features.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Brass/copper (mm) | 0.5-1.5 | 0.5-2 | 0.5-3 |

Galvanized sheet (mm) | 0.5-3 | 0.5-4 | 0.5-6 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times

Product specification of Handheld Laser Welding Machine

Model | ST-FW1500H | ST-FW2000H | ST-FW3000H |

Power | 1500W | 2000W | 3000W |

Beam quality | ≤1.2 M⊃2; | ≤1.3 M⊃2; | ≤1.5 M⊃2; |

Laser wavelength | 1080nm |

Light exit mode | QCW /PWM /CW |

Max modulation frequency | 1000HZ |

Output power stability | <3% |

Aiming positioning system | Built-in Red Light |

Terminal type | QBH |

Delivery cable length | 10M (can be customized) |

Power supply | AC220V±10%, 50/60Hz |

Cooling system | Water Cooled with automatic pumping function |

working environment | Temperature 5-45°C /humidity 10-90% |

Applicable material | Almost all metal materials such as carbon steel, stainless steel, aluminum, brass and galvanized sheet. |

Net weight/gross weight | 140KG/170KG | 220KG/260KG | 270KG/320KG |

Machine size | 1000*500*1000mm | 1500*850*980mm | 1500*850*980mm |

Application materials of Handheld Laser Welding Machine

It can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for various welding between different materials, including copper – brass, titanium-molybdenum, titanium- gold, nickel-copper, etc.

Application industry of Handheld Laser Welding Machine

Widely used in all kinds of sheet metal, molds, chassis, power distribution cabinets, kitchen and bathroom products, all kinds of hardware lighting, advertising signs, door and window frames, handicrafts, household products, food machinery, medical equipment, auto parts and other industries.

Quality assurance

1.. Every production process has a special person to test to ensure quality

2. Have professional engineers to check the quality

3. All products have passed CE, FDA, ISO9001 and other certifications

4. Suntop Laser Welding Machine is subjected to strict tests and continuous 24-hour laser beam output before leaving our factory to ensure 100% machine stability

Packing List:

Wooden case, 1pcs/case

Water-cooled base unit

10m laser welding gun cable (15 meters cable length optional)

Welding nozzle tips*7

Laser safety glasses*1

Protective lens*5

USB*1

Laser inspection report

FAQ

1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.