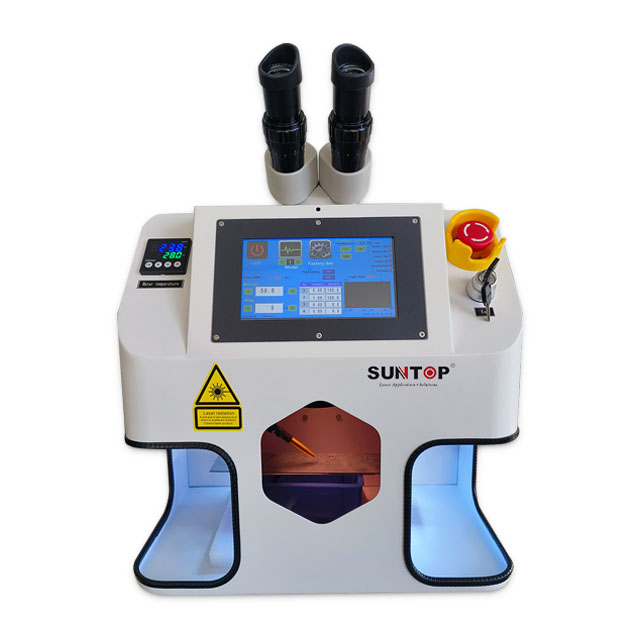

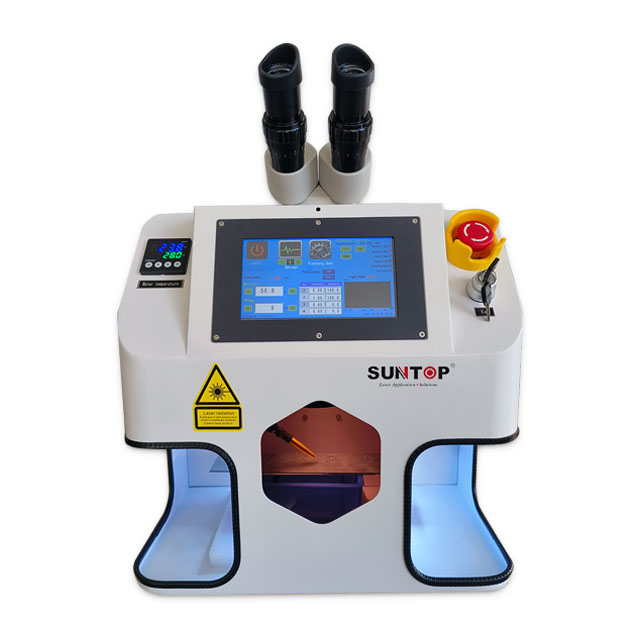

1. High-precision welding

The mold laser welding machine uses a laser beam for welding, which can achieve extremely high positioning accuracy. It is suitable for welding complex shapes and tiny parts, ensuring the high quality and consistency of the welded joints.

2. Small heat-affected zone

The heat-affected zone generated by laser welding is small, which reduces the deformation and stress of the material, helps to maintain the integrity of the base material, and is particularly suitable for heat-sensitive materials.

3. Fast welding

The laser welding speed is fast, which can significantly improve production efficiency, meet the needs of large-scale production, and complete multiple welding tasks in a short time.

4. Wide material adaptability

The laser welding machine can weld a variety of materials, including stainless steel, aluminum, copper and its alloys, etc., with a wide range of applications and suitable for various industry needs.

5. Reduce human errors

The machine is equipped with an automated control system, which can reduce errors caused by human operation and improve the consistency and reliability of welding.

6. Reduce welding deformation

The heat input during laser welding is relatively small, which can effectively reduce the deformation caused during welding, especially in the welding of thin plate materials.

7. Energy saving and environmental protection

Compared with traditional welding methods, laser welding technology consumes less energy, and produces less smoke and harmful gases during welding, which helps to improve the environmental quality of the factory.

8. Repair and composite welding

Laser welding machines can be used for mold repair and composite welding, which can effectively repair worn or damaged mold parts, extend the service life of the mold, and reduce production costs.

9. Flexibility

The machine can flexibly adjust parameters according to different welding requirements, and is suitable for a variety of welding processes, such as spot welding, seam welding, etc., to meet various application scenarios.

Mold laser welding machines not only improve welding quality and efficiency, but also effectively reduce production costs, bringing new opportunities for the development of the manufacturing industry. Click here to contact Suntop Laser today to learn more

Model | ST-WY150/200 |

Max. laser power | 150W/200W |

Laser wavelength | 1064nm |

Total power consumption | 5KW |

Laser focus | 110mm |

Laser pulse repeatable frequency | ≤0.1-20Hz |

Water T.M Protection | 10-30 degree |

Laser pulse width | ≤20ms |

Laser protection gas | 1 path |

Power supply | 220V/50Hz/20A |

Dimension | 940*650*750mm |

Net weight of machine | 80KG/90KG |

What Materials Can be Welded? Widely used in a variety of metal materials, including gold, silver, titanium alloy, stainless steel, aluminum alloy, etc. Also can be used for high alloy steel, hot forged high alloy steel, nickel tool steel, high-grade steel, copper alloy, beryllium copper, high toughness aluminum alloy and other metal materials.

What is Laser Welding Used For?

Widely used in jewelry, medical parts, watch hairsprings, integrated circuits, various small heat-sensitive parts for precision welding, electronics, communications, machinery, automobiles, gold jewelry and other industries. It is also widely used in aviation, aerospace, sporting goods, golf heads, medical equipment, aluminum alloy dentures, especially for gold and silver jewelry hole filling, spot welding seam pattern, inlay parts and claw feet.

Reasons for choosing Suntop Laser as a laser welding machine supplier may include the following aspects:

Technical Strength

Suntop Laser has many years of R&D experience in the field of laser welding technology and is committed to providing high-performance, high-precision laser welding solutions. Their equipment is usually equipped with the latest laser technology to ensure welding quality and speed.

Product Variety

Suntop Laser offers a variety of models of laser welding machines for different materials and welding needs. Whether it is for fine welding of precious metals or welding of thicker materials, Suntop has corresponding products to meet customer needs.

High Quality

Suntop Laser's equipment is known for its high quality and long-term durability. Their products undergo strict quality control to ensure the stable operation of the equipment in a high-intensity working environment.

After-sales Service

Suntop Laser provides thoughtful after-sales service, including technical support, equipment maintenance and training, to ensure that customers can get timely help and support when using the equipment.

Flexible Customized Service

According to the needs of different customers, Suntop Laser provides customized solutions, which can adjust and optimize the equipment according to specific application scenarios and requirements.

Cost-effectiveness

Although high-performance equipment is usually more expensive, Suntop Laser has not ignored the competitiveness of price. Through reasonable pricing and excellent quality, their products are considered to have a high cost-effectiveness.

Through the above points, you can have a deeper understanding of why to choose Suntop Laser. In the selection of laser welding equipment, Suntop Laser may be a very good choice. Click here to contact Suntop Laser now to get more information and prices of laser welding machines.

1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What is a laser welding machine?

Laser welding machine is a device that uses a high-energy laser beam for welding. It achieves the connection of parts by focusing the laser beam on the metal surface to melt it.

6. What are the advantages of laser welding over traditional welding methods?

Laser welding has the advantages of high welding speed, high precision, small heat-affected zone, wide application of materials, less pollution, and automation, which is better than traditional welding methods.

7. How easy is the operation of a laser welding machine?

Laser welding machines usually have a user-friendly interface, and most operators can master the operation of the equipment through brief training. At the same time, many devices have automation functions to simplify the operation process.

8. What is the maintenance frequency of a laser welding machine?

The maintenance of a laser welding machine usually includes regular inspection of the laser components and optical path, maintenance of the cooling system, and cleaning of the equipment. The specific maintenance frequency can be referred to the equipment manual.

9. Does the laser welding process require special safety measures?

Yes, specific safety measures need to be followed during laser welding. Operators should wear laser protective glasses and ensure that the working area is closed to avoid the health effects of laser radiation and harmful fumes.