1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

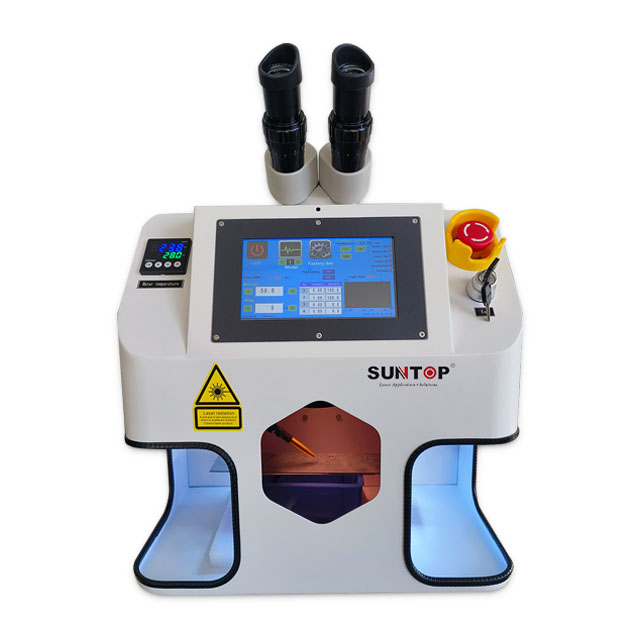

5. What is a mini jewelry laser welder?

A mini jewelry laser welder is a small laser welding device designed for jewelry manufacturing and repair, capable of welding metals and other materials with high precision. It is compact and suitable for use in small studios or personal workshops.

6. What are the advantages of using a mini jewelry laser welder?

Mini jewelry laser welders have the advantages of high precision, easy operation, low heat impact, faster production speed, strong environmental protection, and easy maintenance, making them suitable for jewelry designers and manufacturers.

7. How to choose a suitable mini jewelry laser welder?

When choosing the right equipment, factors such as the type of material being welded, welding depth, power of the equipment, user-friendliness, after-sales service, and budget should be considered.

8. Is the maintenance of a mini jewelry laser welder difficult?

Relatively speaking, the maintenance of a mini laser welder is relatively simple. Regularly checking the welding lens, cleaning the optical components, and keeping the equipment dry and clean can effectively extend its service life.

9. Does operating a mini jewelry laser welder require special skills?

Although the operation of the mini laser welder is relatively simple, users should receive proper training before operation to ensure correct and safe use of the equipment and obtain the best welding results.

10. Is the mini jewelry laser welder limited by the type of material?

Yes, although the mini laser welder can handle a variety of metals, such as gold, silver, platinum, etc., the welding characteristics of different materials are different, and users need to adjust the equipment parameters according to the material type.

11. Can the mini jewelry laser welder be used at home?

Yes, the mini jewelry laser welder is compact and suitable for use at home. Users need to ensure adequate ventilation before use and follow safe operating specifications.