Details Product Parameters Samples Video

Features of metal tube laser cutting machine

1. With CYP pipe cutting software, it can directly accept drawings from 3D drawing software to 2D drawing software. Drawings can be displayed directly on the computer, which is more convenient and faster.

2. High-performance, imported original fiber laser, stable performance, and a life span of more than 100,000 hours

3. Electric self-centering chuck, without manual adjustment, any material with a diameter of 20-150mm does not need to be centered

4. The front and rear chucks and drill bits of the machine adopt servo motor drive system, which can cut without shaking, with high precision and good synchronization.

5. One machine with two cutting functions, not only can cut plates, but also can cut different types of metal pipes. It can save more than 50% space and effectively improve the work efficiency of end users.

6. Auto-following system for calibrating and auto-following the wavy metal plate.

Details of metal tube laser cutting machine

1. Cast aluminum beam

The overall cast aluminum beam is refined through artificial aging and solution treatment, which endows the beam with excellent integrity, rigidity and good toughness.

Light weight, corrosion resistance, oxidation resistance, low density, fast cutting of various graphics while satisfying the precision.

2. Machine tools

A high-power machine tool with a hollow structure is welded with thick steel plates, and the weight of a single machine tool reaches 4 tons. Effectively reduce the heated area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

3. Laser cutting head

The focal length scale can be adjusted flexibly, no need to manually adjust the focus, and it is easy to operate. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates, and automatically cut materials of different thicknesses.

4. High quality guide rail and rack and pinion drive

High rigidity, stable operation, low noise, smooth operation, and reduced impact vibration.

5. Automatic lubrication system

The timing and quantitative lubrication system of the equipment is not controlled by the position and direction, which reduces the maintenance time of the equipment.

Accelerate machine automation and extend drive mechanism life.

Equipped with an independent early warning system to provide early warning functions.

6. Professional software operating system

Professionals can design various graphics or text at will, which is convenient for editing and modifying the cutting path. Scientific man-machine interface, flexible processing, simple operation and high efficiency.

Advantages of metal tube laser cutting machine

1. One machine with two functions, integrating plate cutting and pipe cutting, capable of processing various metal materials and various pipes and plates.

2. The repeated positioning accuracy of the machine tool can reach 0.02mm, and the cutting acceleration is 1.5G. The working life is up to 10 years.

3. The cutting speed is fast, the quality is good, the kerf is small, the deformation is small, the cutting surface is smooth and beautiful, and no follow-up treatment is required.

4. Auto-following system for calibrating and auto-following the wavy metal plate.

5. Support bevel cutting, double chuck clamping, suitable for all kinds of irregular pipe fittings.

6. It has an automatic alarm function for the abnormal working status of the equipment, and pushes it to the operation interface through the control center, which improves the efficiency of equipment abnormal troubleshooting, reduces potential safety hazards, and reduces maintenance costs.

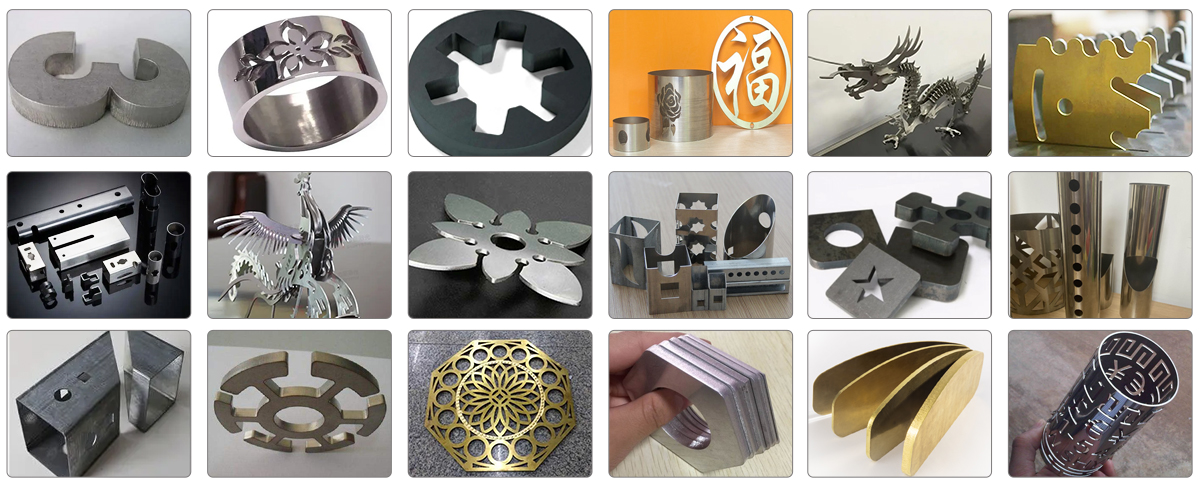

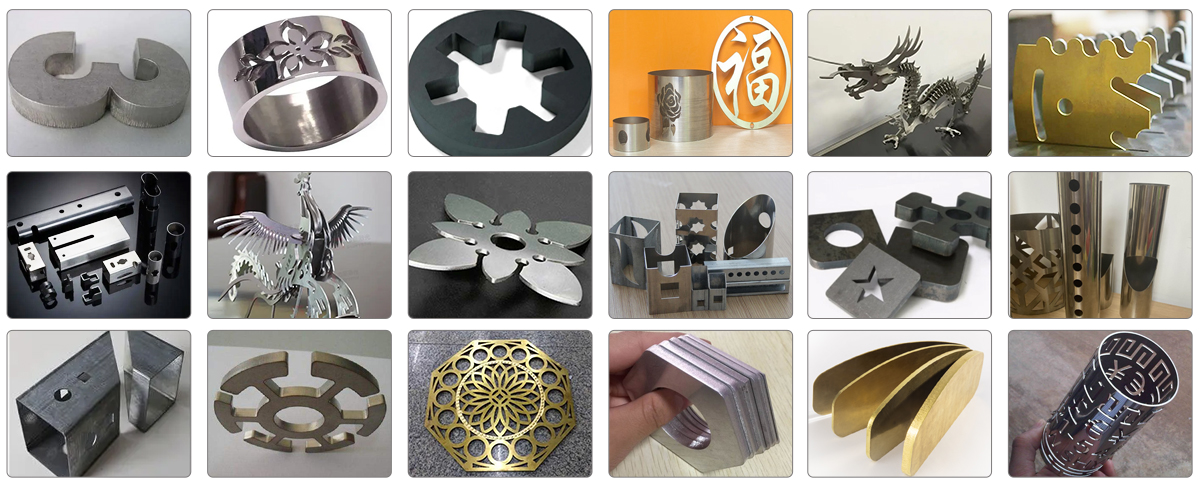

Metal tube laser cutting machine application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Steel metals processing, advertising sings production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, metal board, kettles, medical microelectronics, hardware, knife measuring tools, petroleum and pipe material, fitness equipment and other pipe material mainly mechanical processing, automotive manufacturing, machine cabinet and other board materials mainly mechanical processing, etc. and other metal and tubes processing industry.

Parameters of metal tube laser cutting machine

Model | ST-FC3015R/ST-FC6015R/ST-FC6020R/ST-FC4020R |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (6000*1500mm, 6000*2000mm, 4000*2000mm) |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120meter/min |

Transmission system | Double rack & pinion and servo drive |

Tubes cutting capacity (standard) | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters |

Chuck type | Manual type or pneumatic self-centering chuck |

Maximum acceleration | 1.5G |

Power consumption | 6KW (based on laser power 1KW) |

Power supply | Three phase 380V/50Hz or 60Hz |

Machine weight | 7250Kg |

Overall size | 5050*2480*1830mm (L*W*H) |