Details Product Parameters Samples Video

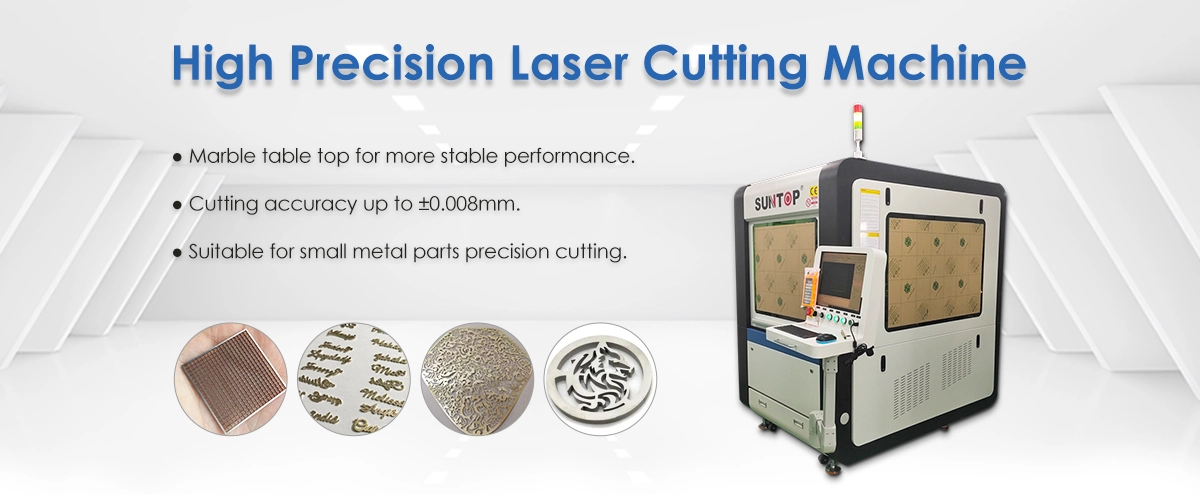

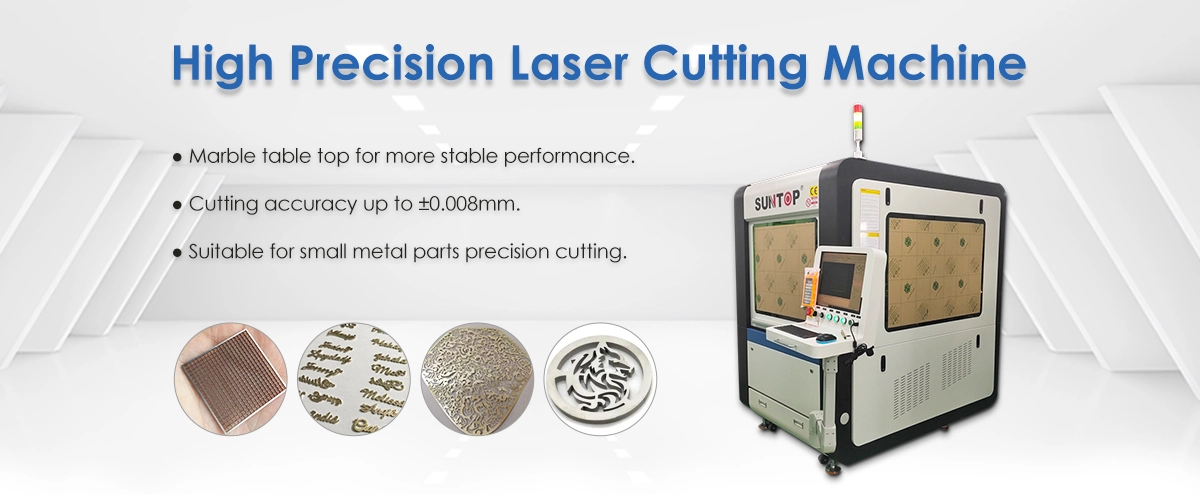

Features of metal laser cutter near me

● Integrated design, compact and reliable structure, safe, practical and reasonable.

● Adopting Swiss Raytools laser cutting head, equipped with dynamic auto focus system, which can keep the same distance between the metal sheet and the laser head to achieve precise cutting effect.

● Adopting imported servo motor and precision guide rail, stable, high cutting precision and long service life.

● Features a red light indicator and pre-run function to find the exact cutting position.

● Imported laser generator with stable power, strong continuous working ability and long service life (no problem for 100,000 hours).

● Energy saving and environmental protection, the photoelectric conversion rate can reach more than 30%, and the power consumption is low.

Details of metal laser cutter near me

1. Brand laser

Imported lasers are used, with stable performance, high precision, and a service life of up to 100,000 hours.

2. Auto focus laser cutting head

The focal length can be automatically adjusted according to the thickness of the material, and the cutting speed can be cut at a high speed.

3. Fast response to high-precision CNC and transmission system

It adopts marble base and gantry mobile platform structure machine tool, international famous brand linear motor or linear guide rail and precision screw drive, and bilateral servo motor synchronous drive to ensure stable transmission under high-speed cutting state and maintain excellent precision and speed. Greatly improve the long-term high-speed and stable operation of the bed.

4. Independent research and development of gas path control system

Capacitive sensors can easily realize functions such as height automatic tracking, active collision avoidance, segmented perforation, and automatic search. Fast speed, high precision, simple operation, greatly improving the quality of cutting and saving costs.

5. Integrated safety design

One-piece closed structure machine, the safety door filters the laser beam, does not hurt the eyes, prevents the debris from splashing on the human body during the cutting process, and protects the safety of the operator.

6. Professional cutting software

High-efficiency automatic typesetting function, automatic optimization of cutting path, reducing sheet waste generation. With a high-definition screen, the work is convenient and efficient.

Advantages of metal laser cutter near me

● High precision: Able to achieve very fine cutting, with flat and smooth cutting lines and precise incision size.

● High-speed processing: Laser cutting has fast operation speed and high production efficiency. It is suitable for mass production and high-demand processing tasks.

●Wide range of application: Suitable for a variety of metal materials, including stainless steel, aluminum alloy, copper, steel, etc.

● Non-contact processing: Laser cutting is a non-contact processing, which avoids damage and scratches caused by contact with the workpiece.

● Small thermal impact: The heat-affected area during laser cutting is small, reducing the possibility of deformation and material damage.

● Complex graphics processing: Automatic cutting can be performed according to the graphic trajectory designed by CAD, suitable for processing various complex-shaped parts.

● High degree of automation: Jin is equipped with an intelligent control system to realize automatic operation, automatic tool replacement and other functions, and has high work efficiency.

● Energy saving and environmental protection: Laser cutting is an efficient and energy-saving processing method that does not require the use of chemical solvents and reduces waste production.

Application materials of metal laser cutter near me

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass, silver, gold and other kinds of metals.

Application industry of metal laser cutter near me

Widely used in gold and silver jewelry, precision electronics, auto parts, high-precision instruments, precision machinery, hardware accessories, bathroom accessories, environmental protection equipment, medical equipment, electronic communications, household appliances, aerospace, gift crafts, tool processing, decoration, molds, advertising, mobile digital, sheet metal processing, hardware products and other manufacturing and processing industries.

Parameters of metal laser cutter near me

Model | ST-FC6060/ST-FC1390/ST-FC2010 |

Table Max. cutting size | 600*600mm/1300*900mm/2000*1000mm (other sizes can be customized) |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choose) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1700*1190*1850mm (depending on actual model) |