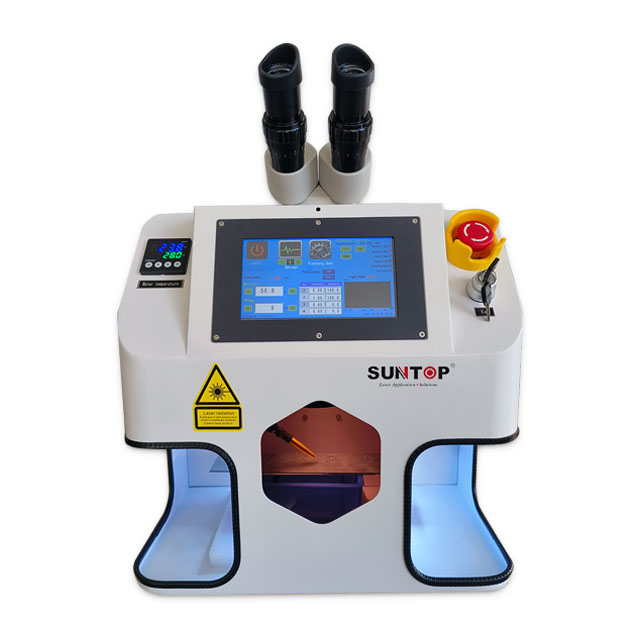

Jewelry laser welding machines have a wide range of applications in jewelry manufacturing and repair, mainly in the following aspects:

1. Metal connection

Welding jewelry chains: used to connect bead chains, including making and repairing metal chains to ensure the strength and beauty of the chains.

Inlaying gemstones: During the gemstone inlay process, the brackets can be accurately welded to fix the gemstones and ensure their stability.

2. Fine repair

Repairing damaged jewelry: For broken or deformed jewelry, laser welding can effectively repair it and restore its original shape and beauty, especially when repairing very small and complex structures, the high precision of laser welding is particularly important.

Repair and reinforcement: For wear or damage during wearing, laser welding can be used for repair and reinforcement to improve the durability of jewelry.

3. Complex design production

Realize complex designs: Laser welding equipment can handle very small and complex workpieces to meet the needs of jewelry designers for unique and fine designs.

Multi-layer structure: When making multi-layered jewelry, laser welding can achieve seamless connection of different materials and maintain the integrity of the design.

4. Welding of different materials

Welding of different metals: Metals commonly used in jewelry such as gold, platinum, silver and palladium, laser welding can effectively connect different metal materials without oxidation and discoloration.

5. Micro welding

Handling tiny parts: Laser welding machines are suitable for connecting tiny parts. They can achieve high-precision connections without affecting other parts, and are very suitable for small jewelry.

6. Experimentation and customization

Personalization: Laser welding technology supports small-batch personalized customization. Designers can quickly meet customer requirements and flexibly respond to market demand.

Rapid prototyping: In the jewelry design stage, laser welding can be used to quickly make models and prototypes to accelerate the design process.

In addition to the above applications, it is also widely used in aviation, aerospace, sporting goods, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles and other industries, especially for gold and silver jewelry hole filling, spot welding seam pattern, inlay parts and claw feet.

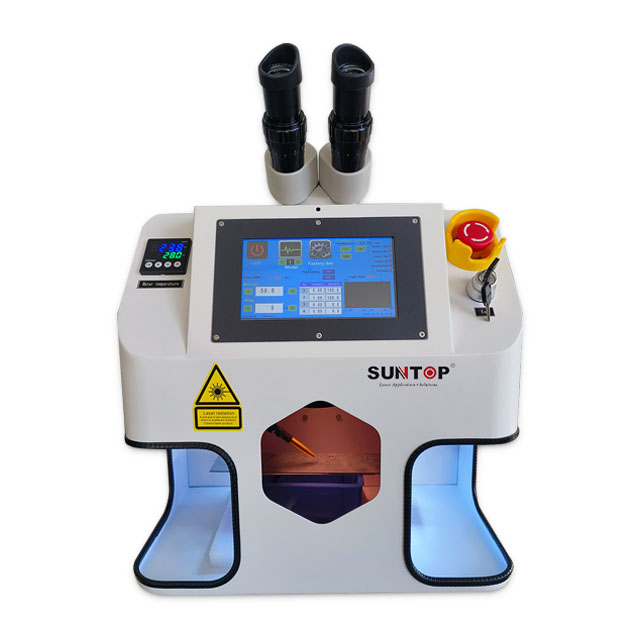

In summary, the role of jewelry laser welding machine in the jewelry industry is crucial, providing efficient and precise welding solutions, which can effectively improve the quality and efficiency of jewelry production. Due to its operational flexibility and adaptability, laser welding has become an indispensable part of modern jewelry craftsmanship. Click here to contact Suntop Laser now for more information.