1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

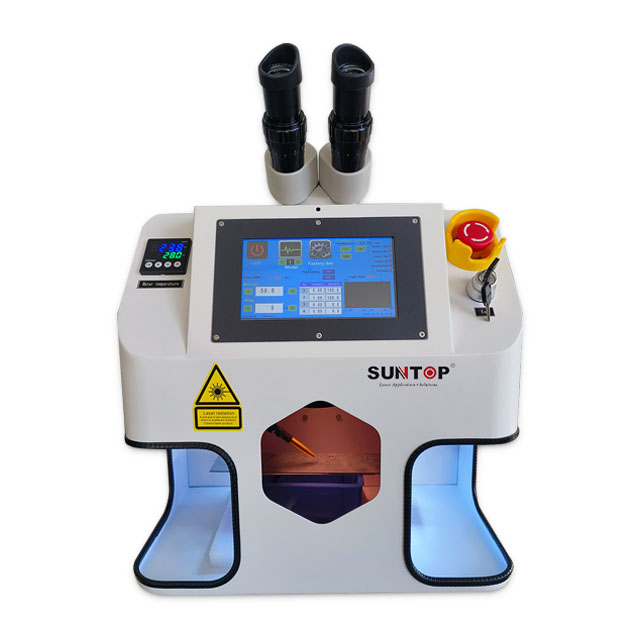

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. Does the use of laser spot welding require professional training?

Although the initial operation is relatively simple, in order to ensure safety and welding quality, it is recommended that operators receive professional training and understand the use skills and maintenance knowledge of the equipment.

6. What should be paid attention to during laser welding?

When using a laser spot welding machine, the following points should be noted:

Ensure a safe and clean working environment.

Wear appropriate protective equipment (such as protective glasses).

Regularly check and maintain the equipment to ensure its normal operation.

7. What is the difference between laser welding and traditional welding?

Laser welding mainly relies on heat focusing to perform local melting in a very small area, with higher welding accuracy and less thermal impact. Traditional welding methods usually result in a larger heat-affected area, which may cause deformation or damage to surrounding materials.

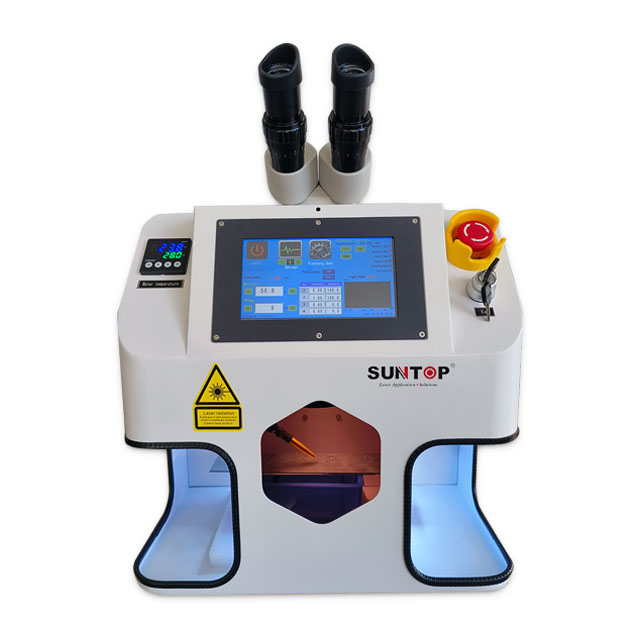

8. What are the maintenance tasks of a laser spot welding machine?

Maintenance includes regular cleaning of the laser optical path and lens, replacement of consumables, checking the status of the laser, calibrating the equipment, and ensuring that the operating interface is normal.

9. How to choose a suitable laser spot welding machine?

When choosing a suitable laser spot welding machine, the following factors should be considered:

Type and thickness of welding material.

Expected welding accuracy and application requirements.

Functional configuration and ease of use of the equipment.

After-sales service and technical support.

10. Does the laser spot welder consume energy?

The energy consumption of the laser spot welder is relatively low, but the specific energy consumption is affected by the equipment power and workload. In general, it has a high energy utilization ratio.