Details Product Parameters Samples Video

Features of laser marking machine for gold jewellery price

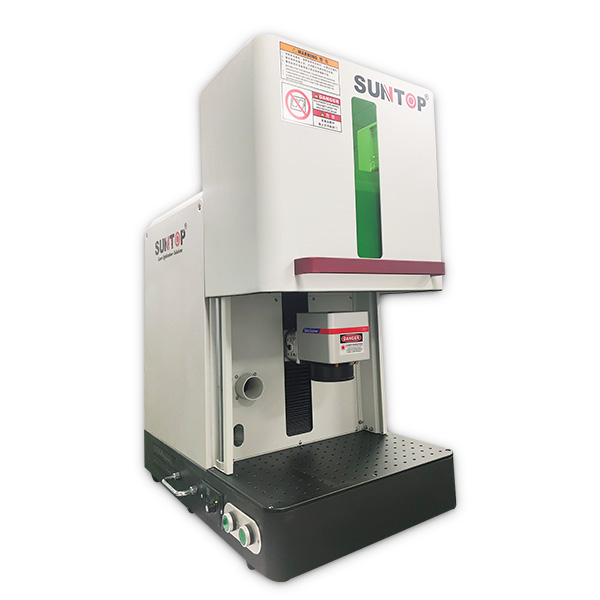

1. Adopting European CE standard laser protection glass fully enclosed design, laser processing visualization, safer operation.

2. CNC full cabinet compact laser marking machine is equipped with electric lift focus and emergency stop button, more convenient to use.

3. Built-in red light is used to preview the marking position, easier and more accurate to find the laser focus.

4. Using high-precision brand-name wavelength F-theta lens, it can realize high-speed and high-precision laser marking, and the text and image will not be distorted for a long time.

5. Equipped with exhaust dust removal system to keep the working environment clean and prolong the service life of optical components.

6. Humanized operation, long-term operation without failure, fully meet the needs of continuous industrial work.

Details of laser marking machine for gold jewellery price

1. Brand laser

It has stable performance, high photoelectric conversion efficiency, and does not require maintenance of the laser and beam transmission system, which can save a lot of maintenance costs and time.

2. High speed galvanometer

High-precision laser scanning galvanometer, fast and clear, with high stability.

3. High field lens

The use of quartz high-transmission coating field lens greatly improves the ability of edge beam focusing, with high light transmittance and good marking effect.

4. Enclosed protective cover

Humanized design, closed safety cover, flexible adjustment of lifting speed.

Advantages of laser marking machine for gold jewellery price

● High precision: With high-precision processing capabilities, fine text, patterns or marks can be achieved without damaging the surface quality of gold jewelry.

● High-quality processing: Laser marking on the gold surface has strong durability, is clearly visible, is not easy to wear or fade, and maintains long-term beauty.

● Diversified design: A variety of shapes, patterns, and text markings can be achieved to meet the customization needs of different styles and styles.

● High efficiency: Laser marking is easy to operate and fast, which can improve production efficiency and is suitable for batch processing and personalized customization needs.

● Non-contact processing: Non-contact processing technology will not cause surface damage or deformation to gold and maintain the original quality of gold jewelry.

● Environmental protection and pollution-free: There is no need to use chemical dyes or corrosives during the laser marking process, no pollutants are produced, and it meets environmental protection requirements.

Application materials of laser marking machine for gold jewellery price

Suitable for working with most metal marking applications such as gold, silver, stainless steel, brass, aluminium, steel, Iron titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of laser marking machine for gold jewellery price

Widely used in craft gifts, furniture, leather clothing, advertising signs, model making, food packaging, pharmaceutical packaging, electronic components, communications, clocks, glasses, printing plate making, shell nameplates and other industries.

Parameters of laser marking machine for gold jewellery price

Model | ST-FL20PF | ST-FL30PF | ST-FL50PF |

Laser power | 20W | 30W | 50W |

Depth of single marking | 0.01mm | 0.03mm | 0.06mm |

Same pattern marking efficiency | 10s | 7s | 4s |

Whole machine power | 600W/h | 800W/h | 1000W/h |

Marking area | 70*70mm/110*110mm/150*150mm |

Laser wavelength | 1064nm |

Laser source | MAX Brand(Raycus can be choose) |

Control software | EZCAD |

Cooling mode | Air Cooling |

Working accuracy | ±0.002mm |

Marking speed | 0-7000mm/s |

Repetition frequency | 20-100KHz |

Minimum font for marking | 0.15mm |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Net weight/gross weight (KG) | 55KG / 85KG |

Machine dimension | 750*530*910mm (L*W*H) |