Details Product Parameters Samples Video

Features of jewellery laser marking machine price

● High precision: Using high-precision laser beam, it can accurately mark the tiny text and patterns on the jewelry surface without damaging the jewelry surface.

● High stability: The laser output power is stable and the beam quality is high, ensuring long-term and stable marking effect without affecting the quality of jewelry.

● Environmental protection and pollution-free: The laser marking process does not require auxiliary materials such as ink, chemicals, etc., and no waste gas, waste water, or waste is produced, which complies with environmental protection requirements.

● Non-contact marking: The non-contact marking method avoids scratches or damage that traditional engraving tools may cause to the jewelry surface.

● Diversified markings: High-definition, fine and delicate markings can be achieved on jewelry made of different materials, such as patterns, text, QR codes, etc.

● Automated production: Fully automated production and tracking management can be achieved to improve production efficiency and product quality.

Details of jewellery laser marking machine price

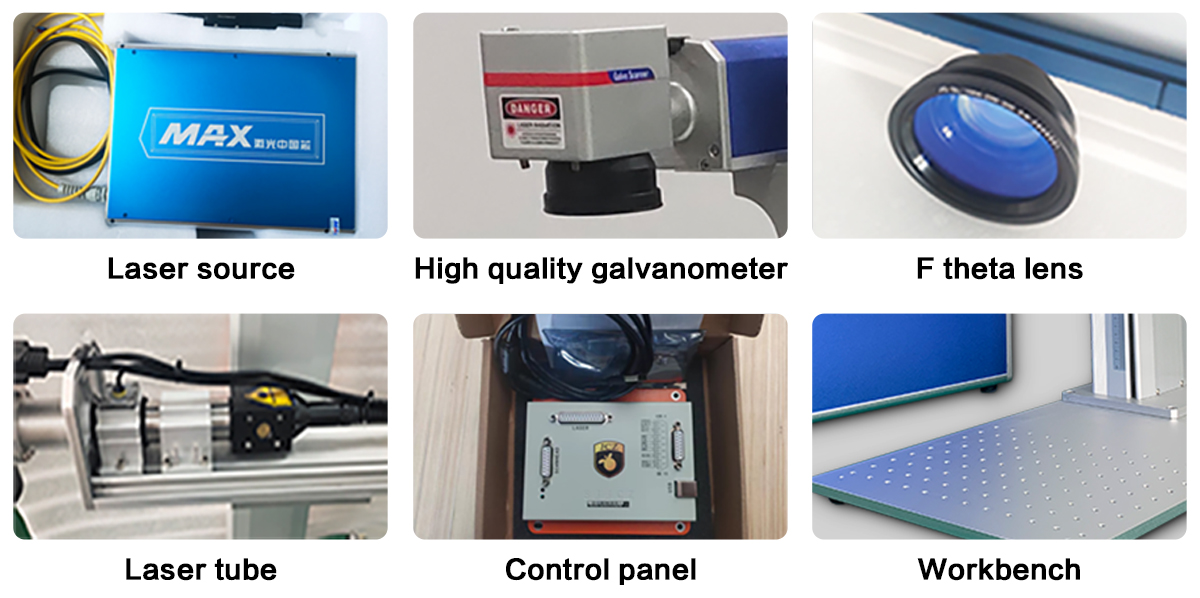

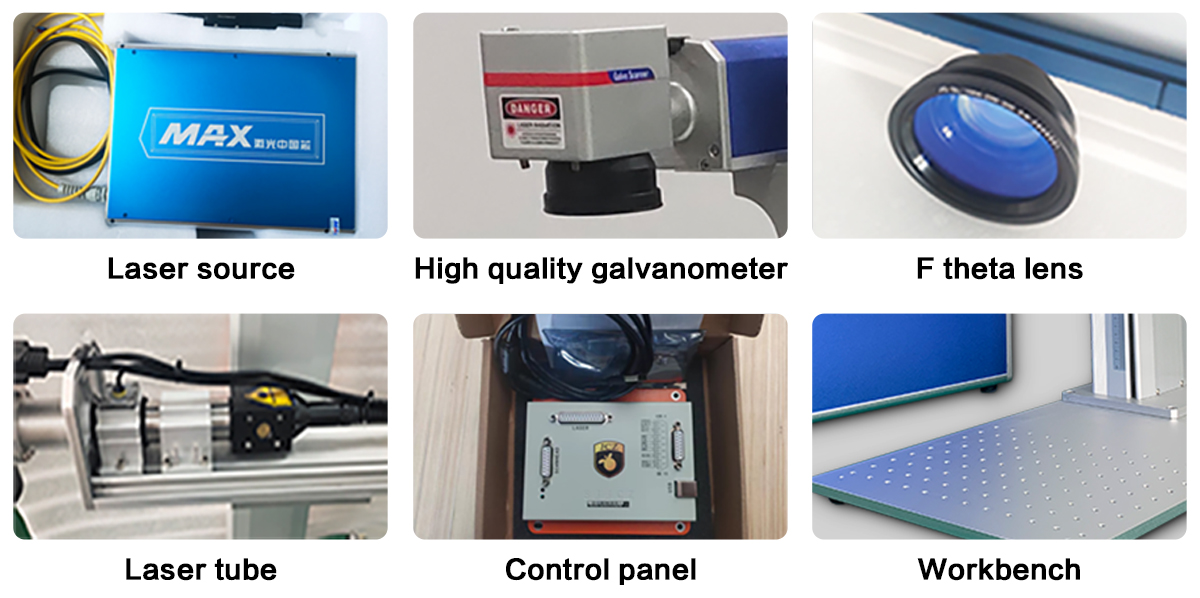

1. Laser source

Suntop's customized pulsed MAX. Lasers with wider adjustable pulse widths from which can achieve the different marking effects with perfect quality.

2. High quality galvanometer

The high-speed digital galvanometer scanning head has good running stability and high positioning accuracy, which can realize high-speed marking and high precision.

3. F theta lens

Smart F theta lens, through which the fiber laser beam is focused to the workpiece surface, the energy is sufficient.

4. Laser tube

Higher scanning speed and marking accuracy.

5. Control panel

BJJCZ brand original EZCAD control system has the characteristics of high stability, easy operation and good performance.

Advantages of jewellery laser marking machine price

● Customization: Customization can be carried out according to customer needs to achieve personalized identification and increase the added value of jewelry.

● High efficiency: With high-efficiency marking capabilities, it can quickly and accurately complete jewelry marking and engraving tasks, improving production efficiency.

● Anti-wear: The laser-marked logo text and pattern are not easy to be worn, and maintain clarity and colorfastness for a long time, making the jewelry more durable.

● High-quality marking effect: The marking content is clear and delicate, which improves the readability of the marking content and enhances the grade and ornamental value of the jewelry.

● Mass production can be achieved: It can be produced in batches, adapt to mass production requirements, and improve the efficiency of the jewelry processing production line.

● Can save costs: Compared with traditional manual lettering methods, it can save labor costs, improve production efficiency, and reduce operating costs.

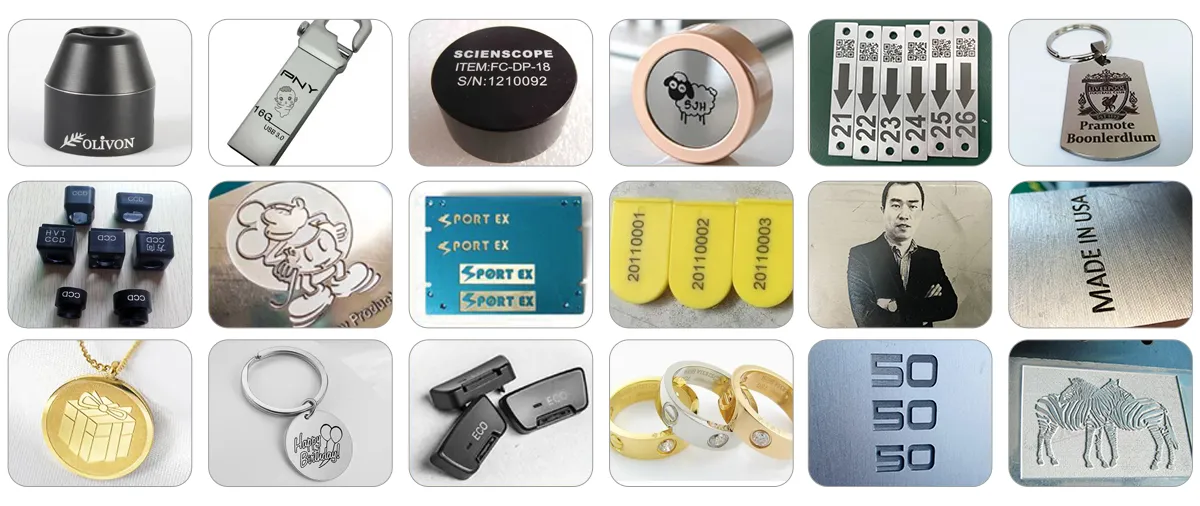

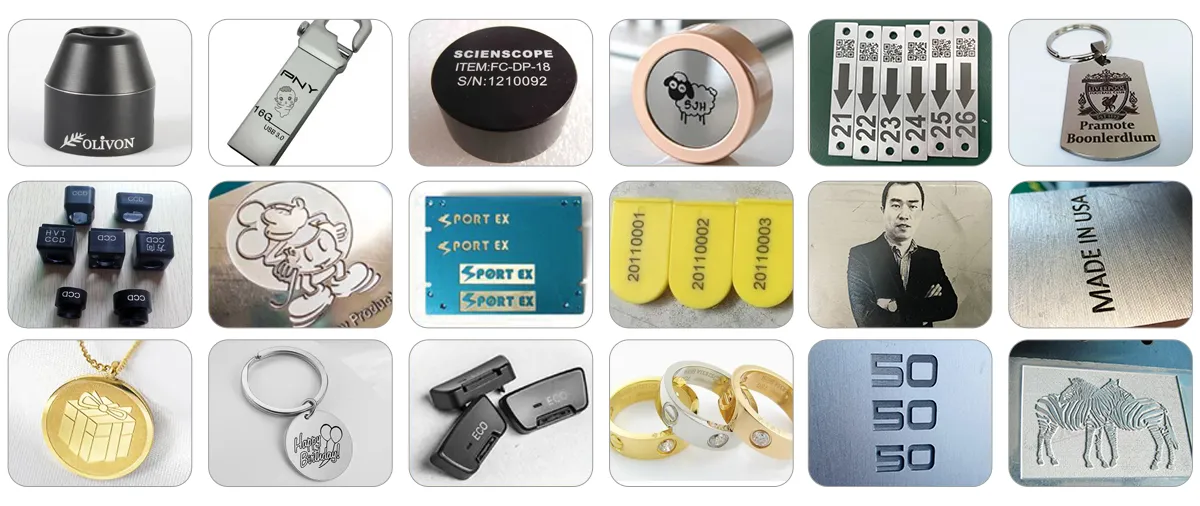

Application materials of jewellery laser marking machine price

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc, and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.

Application industry of jewellery laser marking machine price

Widely used in many industries such as machinery manufacturing, electronic appliances, optical communication devices, lithium-ion batteries, mobile phone parts, auto parts, medical equipment, precision machinery, integrated circuits, instrumentation, computer manufacturing, gold and silver jewelry, craft gifts, clothing and accessories .

Parameters of jewellery laser marking machine price

Laser Power | 20W | 30W | 50W | 60W |

Model | ST-FL20P | ST-FL30P | ST-FL50P | ST-FL60P |

Max Marking Range | 110*110mm /150*150mm | 200*200mm | 300*300mm | 450*450mm |

Depth of Single Marking | 0.01mm | 0.03mm | 0.06mm | 0.07mm |

Same pattern marking efficiency | 10s | 7 s | 4s | 3s |

Whole Machine Power | 600W/h | 800W/h | 1000W/h | 11000W/h |

Laser Type | Fiber Laser |

Laser Source | MAX Brand ( Raycus can choose ) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Working Accuracy | ±0.002MM |

Marking Speed | 0-7000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 1064nm |

Minimum Font for Marking | 0.15mm |

Working Voltage | 220V±10%, 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC, PES, ETC.) |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 50KG |

Machine Dimension | 420*300*550mm (L*W*H) |