Details Product Parameters Samples Video

Features of galvo laser machine price

1. Fully enclosed design, in line with European CE standards, equipped with laser protection glass observation window, easy and safe to operate.

2. Adopting high quality light source, good spot quality, uniform optical power density, stable output optical power, can achieve precision processing.

3. Adopt original control EZCAD control card and software, support two-dimensional and rotary marking, secondary development functions, etc..

4. Scanning head built-in red light for preview marking position, easier and more accurate to find the laser focus.

5. Electro-optical conversion efficiency can reach more than 28%, energy saving and power saving. Non-contact marking, no pollution, no noise, very environmentally friendly.

6. Suntop fiber laser marking machine has passed strict aging test before leaving the factory, and the laser beam is continuously output for 24 hours to ensure 100% stability of the machine.

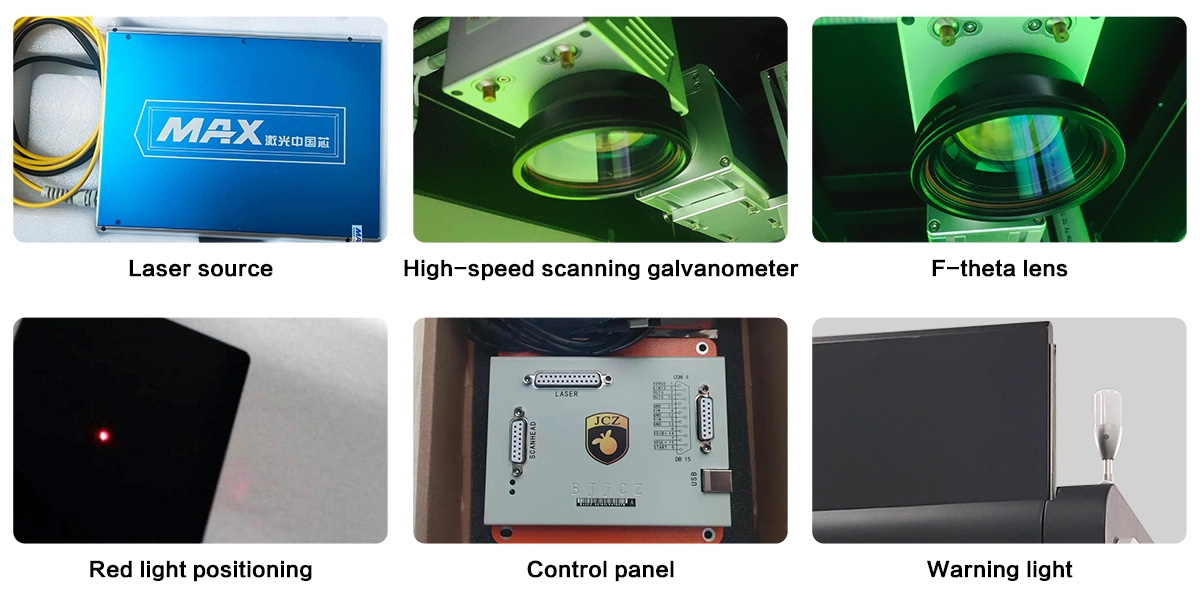

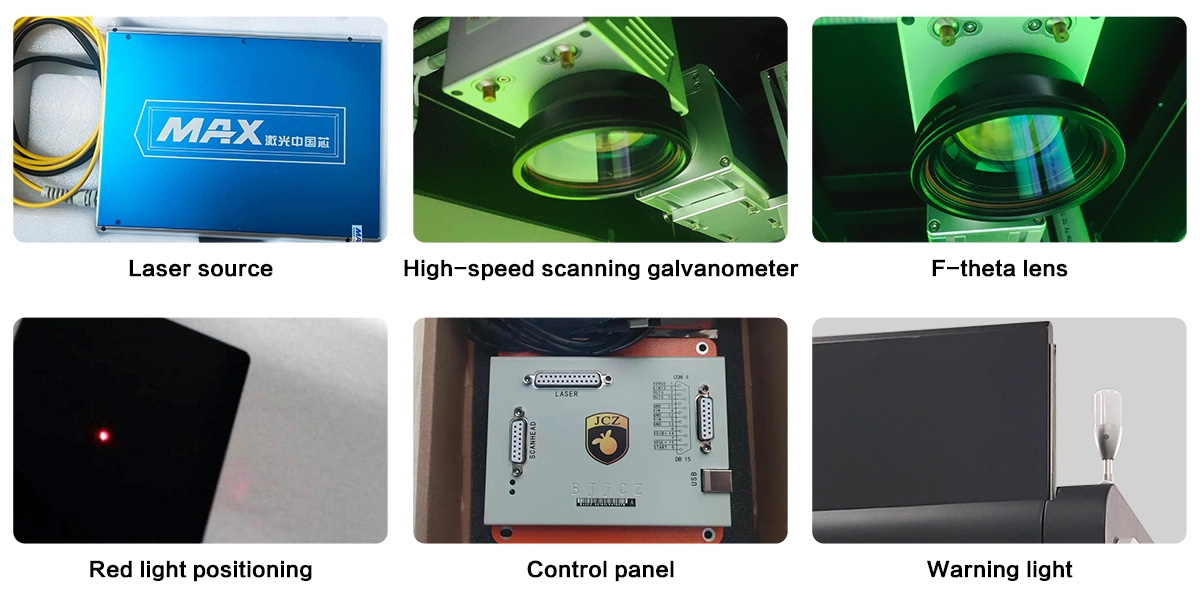

Details of galvo laser machine price

1. Laser

The core component is the laser, which is responsible for generating a high-power, highly stable laser beam, enabling the laser beam to perform marking operations at higher speeds and with greater precision.

2. Oscilloscope system

Responsible for controlling the trajectory and direction of the laser beam. By precisely controlling the movement of the galvanometer system, rapid and precise marking of the laser beam on the material surface can be achieved.

3. Field mirror

Used to diffuse the laser beam and form a certain spot size to adapt to different sizes of the marking area. By adjusting the focal length and angle of the field mirror, precise control of the spot size can be achieved, thus realizing efficient and high-quality marking results.

4. Combining Mirror

It is used to combine the laser beam with the red light in order to observe the accuracy of the marking position during the marking process. Through the merging mirror and the laser beam to achieve the optical path indication, so that the operator can more intuitively observe the state and position of the marking process.

5. Red light indicator

Used to indicate the position of the laser beam, through the closing mirror and laser beam overlap, to achieve the light path indication. During the marking process, the red light indicator can help the operator to quickly locate the marking position and improve the marking efficiency.

6. Control software

It is the core control part, which is used to generate and edit the marking pattern and control various operating parameters of the fiber laser marking machine. Through the control software, automated marking operation can be realized to improve production efficiency and quality.

Advantages of galvo laser machine price

● High-speed marking capability: Using a high-speed galvanometer system, the laser beam can be quickly positioned, scanned and marked.

● High-precision marking: The galvanometer system of the laser marking machine can quickly and accurately react and control the position and direction of the laser beam to achieve precise marking and engraving. With high-precision marking capabilities, small marks and fine pattern engravings can be achieved.

●Multi-material adaptability: Suitable for marking a variety of materials, including metal and plastic. The energy of its laser beam can be adjusted and controlled according to the characteristics of the material to achieve the marking needs of different materials.

● Flexibility and creativity: Flexible operation and creative design capabilities. Users can set different parameters and control modes to achieve marking requirements of different shapes and patterns, including text, patterns, barcodes, QR codes, etc.

● High-efficiency energy consumption ratio: It has high energy utilization efficiency and consumes less energy than traditional marking methods. This not only saves energy but also reduces operating costs.

● Easy operation and maintenance: It is easy to operate and maintain. The operation interface is intuitive and clear, and users can quickly get started and operate it. At the same time, maintenance and repair of the galvanometer system are relatively simple, reducing downtime and costs.

Application materials of galvo laser machine price

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of galvo laser machine price

Electronics and communication products, IC products, wires, cables, computer components and electrical appliances; all kinds of precision parts, hardware tools, instruments and meters, aviation and aerospace appliances; jewelry, clothing, instruments and meters, gifts, office equipment, brand signs, bathroom appliances ; Tableware, food, drinks, tobacco and wine, etc.

Parameters of galvo laser machine price

Model | ST-FL20FB/ST-FL30FB/ST-FL50FB |

Laser power | 20W/30W/50W (optional) |

Marking area | 75mm*75mm/110mm*110mm/150mm*150mm/175mm*175mm/200mm*200mm/250mm*250mm/300mm*300mm |

Laser wavelength | 1064nm |

Working accuracy | ±0.002mm |

Marking Depth | ≤1.2mm |

Minimum font for marking | 0.15mm |

Minimum character | 0.2mm |

Marking speed | 0-7000mm/s |

Operating system | Win7 and Win10/32 bit and 64 bit |

Laser source | MAX Brand ( Raycus can be choose) |

Repetition frequency | 20-100KHz |

Cooling mode | Air Cooling |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Environmental requirements | Temperature: 10-35℃, Humidity: 5-75% |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net weight/gross weight (KG) | 165kg /188kg |

Machine dimension | 860*992*1880mm (L*W*H) |