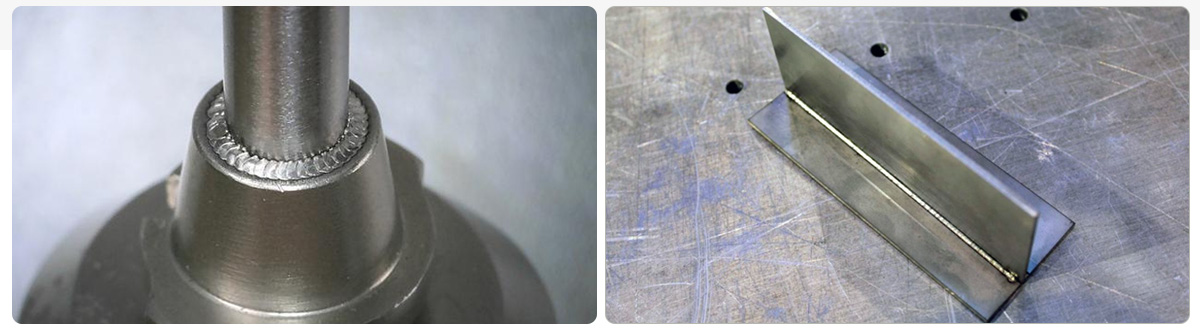

Laser welding is a high-precision, high-efficiency welding method, but control of its processing quality is the focus of attention in the industry. This article discusses the key elements of quality control in laser welding processing. Through comprehensive consideration of these factors, the quality level of laser welding processing can be effectively improved to meet the growing demand for welding.

As a high-precision and high-efficiency welding method, laser welding is widely used in automotive, electronics, aerospace and other fields. However, with the growing demand for welding, how to control the quality of laser welding processing has become the focus of attention in the industry. In this paper, we will discuss the key elements and optimization strategies for controlling quality in laser welding processing.

Laser welding is an efficient and precise processing technology that is widely used in various industries. However, with the increasing demand for welding, how to control the quality of laser welding processing has become the focus of attention in the industry. The following will discuss how to control the quality of laser welding processing.

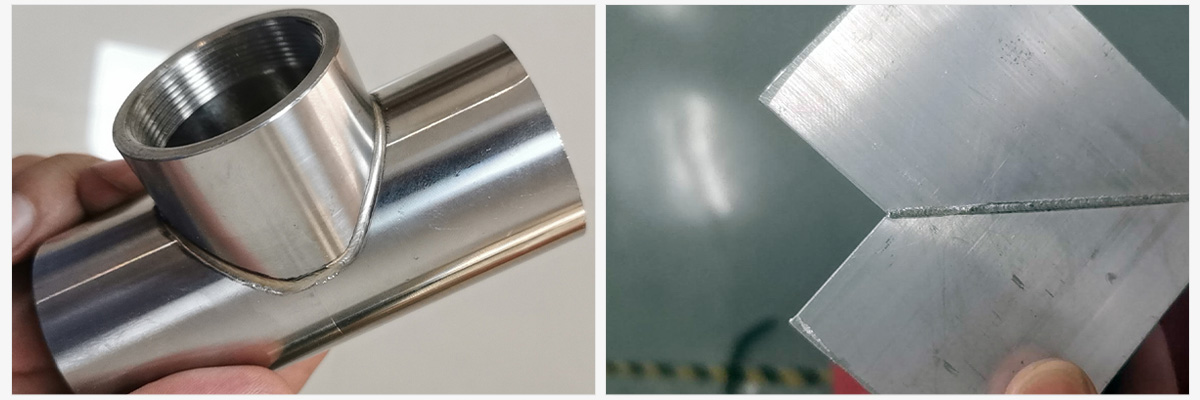

1. Select the appropriate laser welding parameters

The quality of laser welding is affected by laser power, focal length, welding speed and other parameters. Reasonable selection of these parameters, you can effectively control the quality of welding, to avoid the weld is too deep or too shallow and other problems.

2. Control the gas environment in the welding process

Laser welding process, the gas environment has an important impact on the welding quality. Maintaining a suitable gas environment can prevent the occurrence of oxidation and other problems to ensure the quality of the weld.

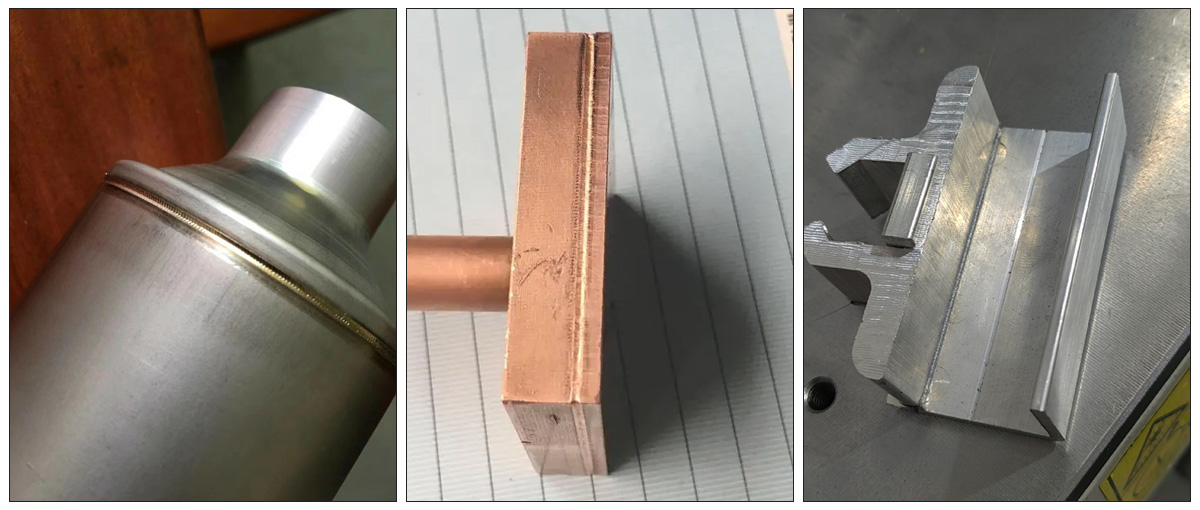

3. Ensure the quality of welding materials

Selection of high-quality welding materials is critical to the quality of welding. The quality of the material directly affects the strength and stability of the welded joint, so be careful when choosing the material.

4. Control welding speed and welding path

Controlling the welding speed and welding path can effectively avoid welding too hot or too fast to ensure the quality of welding. Reasonable welding speed and path is the key to ensure the quality of welding.

5. Preparation before welding

Before carrying out laser welding, we should make adequate preparations, including cleaning the welding surface, debugging equipment and so on. Only by doing these preparations can the welding quality be guaranteed.

6. Regular inspection and maintenance of equipment

Regular inspection and maintenance of laser welding equipment is an important guarantee of welding quality. Timely detection and resolution of equipment problems can avoid welding quality problems caused by equipment failure.

7. Enhance staff training and technical exchanges is also an effective way to improve the quality of laser welding processing

Through regular training and technical exchanges, the staff to master the latest welding technology and quality control methods, improve operational skills and quality control awareness, so as to ensure the stability and reliability of welding quality.

The control of laser welding processing quality is a comprehensive work, which needs to do a good job in laser welding parameters, gas environment, material quality, welding speed and path, preparation and equipment maintenance. Only a comprehensive mastery of these techniques and methods can ensure the quality and stability of laser welding.

Advantages of premium laser welding quality:

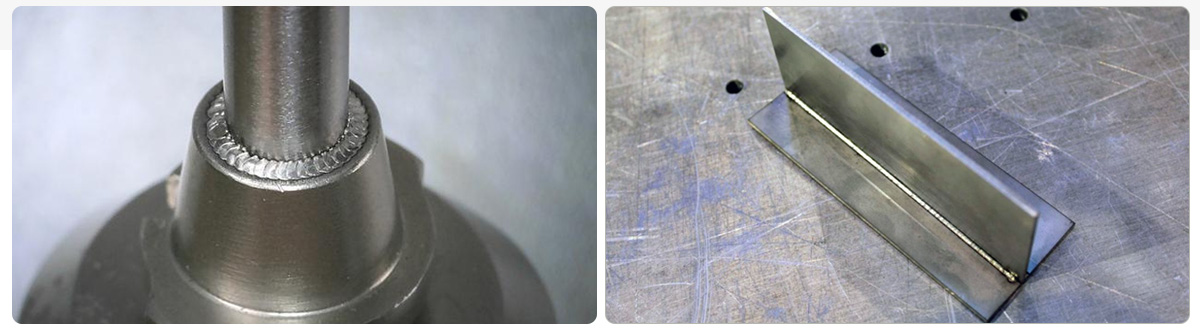

1. Stable quality

Quality laser welding processing quality is stable and reliable, the welded joints are uniform and firm, improving the quality and reliability of products.

2. Fast speed

High-quality laser welding processing speed, can greatly improve production efficiency, shorten the production cycle, reduce production costs.

3. High precision

High-quality laser welding processing has a high energy density and fast thermal response, can realize high-precision welding, to avoid welding deformation and cracks.

4. Environmental protection and energy saving

Laser welding processing does not require the use of welding flux, will not produce harmful gases and slag, in line with environmental requirements, energy saving and emission reduction.

5. High degree of automation

Laser welding processing can be used in conjunction with robots and other automation equipment to achieve fully automated production, improve production efficiency and quality stability.

The quality control of laser welding processing is a systematic process involving multiple links and factors. Through scientific methods and strict management, the quality of laser welding processing can be effectively improved to meet various industrial needs.