Details Product Parameters Samples Video

Features of cnc laser metal cutting machine

1. Imported high-precision double servo drive and guide rail drive, HIWIN embedded guide rail, stable drive and high precision.

2. Both X and Y axes adopt Japanese servo motors, which have high precision, fast speed, large torque, large inertia and stable performance, ensuring the high speed and acceleration of the whole machine.

3. It adopts French Schneider AC servo system, which has high power, strong torque, more stable and fast working speed.

4. The mechanical transmission part has been tested and calibrated by the laser interferometer many times to ensure that the machine can still maintain good and stable accuracy after several years of use.

5. The laser optical path system is stable. After thousands of vibration experiments, the laser optical system is stable.

6. The cutting format is large, and it is suitable for many cutting materials. It supports customization of various cutting formats, and is suitable for almost all metal materials.

7. Compatible with a variety of software, design graphics as you like, simple, flexible, and easy to operate.

Detail fiber laser cutting machine metal

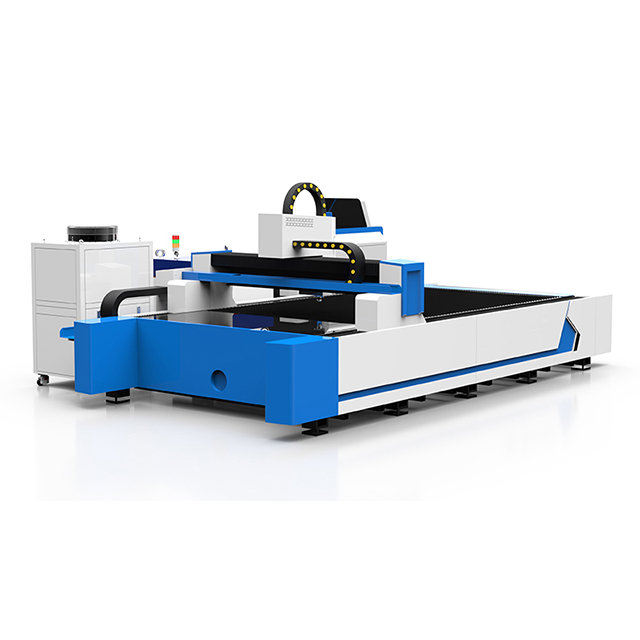

Heavy machine tools

● We use a high-power machine tool with a hollow structure, which effectively reduces the heating area during the laser cutting process. The machine tool will not be deformed after long-term use, and it also ensures good cutting accuracy and greatly improves the stability of the machine. At least use 20 years will not deform.

● Our machine tools are welded with thick steel plates, and the weight of one machine tool alone reaches 4 tons.

● The cheap machine tools on the market are all welded with square tubes. The machine tools are light and thin. After 1-2 years of use, they will deform greatly, and there is almost no cutting accuracy.

Core Part-Laser Head

● Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

● Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

● Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Advantages of cnc laser metal cutting machine

1. High precision, fast speed, narrow slit, small heat-affected zone, smooth and burr-free cutting surface, no deformation.

2. the laser cutting head will not touch the material surface and will not scratch the workpiece.

3. Good processing flexibility, can process any graphics, also can cut shaped materials such as pipes.

4. Automatic nesting saves material and maximizes the utilization of material.

5. Save investment in tooling, reduce production costs, especially suitable for processing large products.

6. Safe and environmental protection, laser processing less waste, low noise, clean, safe, no pollution, greatly improve the working environment.

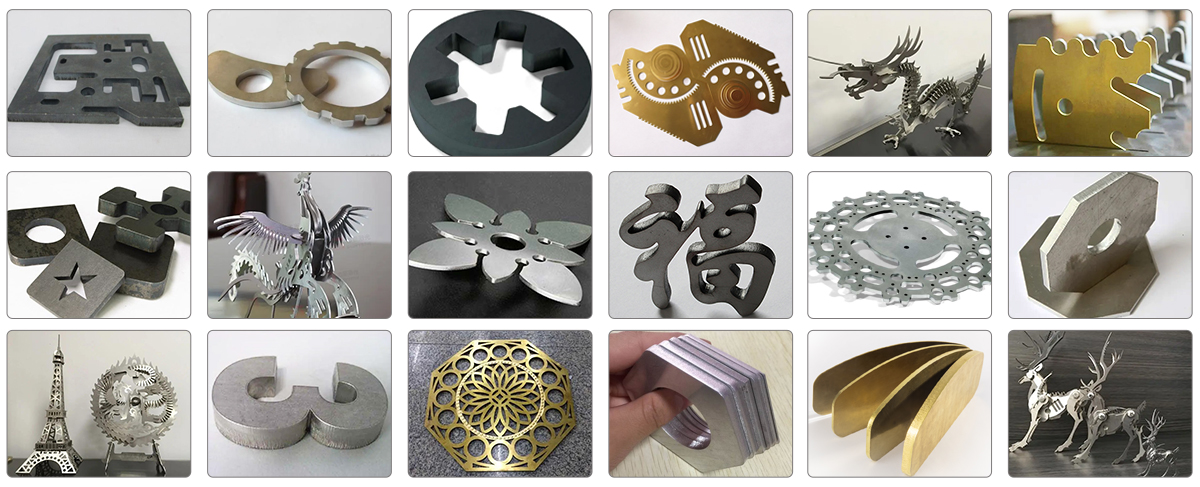

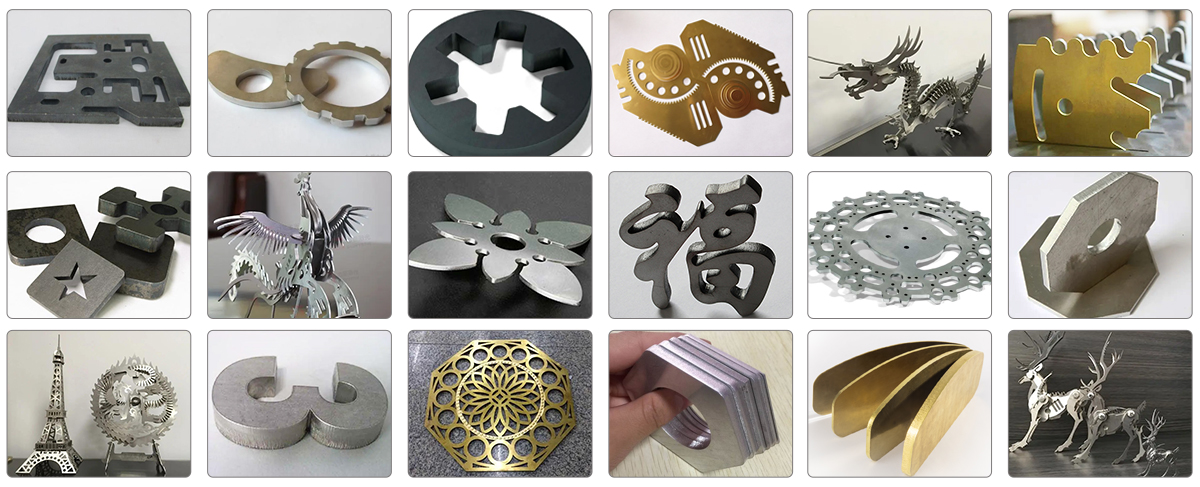

CNC laser metal cutting machine application

Application materials

mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, steel, various alloy plate, rare metal and other metal materials.

Application industry

Widely used in sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring sheets, circuit boards, electric kettles, medical micro Electronics, hardware, knife measuring tools and other industries.

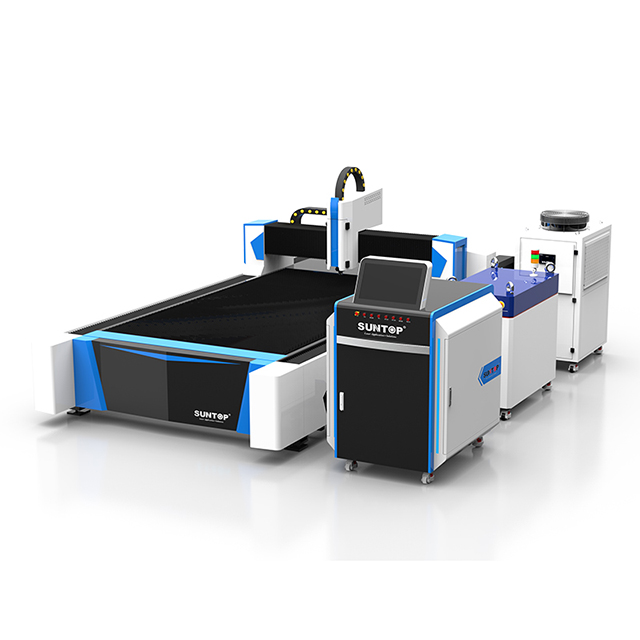

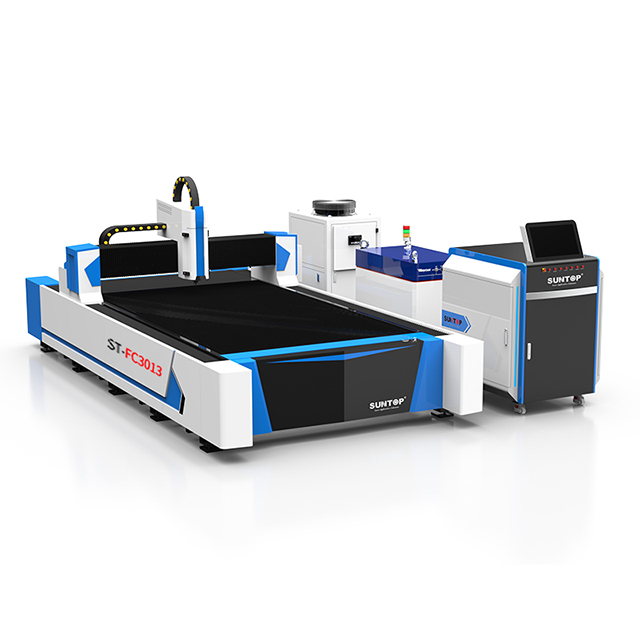

Parameters of cnc laser metal cutting machine

Machine model | ST-FC3015/ST-FC3013/ST-FC4020/ST-FC6020/ST-FC4015/ST-FC6015 |

Working area | 1500*3000mm/1300*3000mm/4000*2000mm,/6000*2000mm/4000*1500mm/6000*1500mm (support customization) |

Laser power | 1000W - 20KW |

Transmission system | Double rack & pinion and servo drive |

Maximum speed | 60m/min |

Positioning accuracy | ±0.03mm/1000mm |

Repositioning accuracy of clamp | ±0.02mm/1000mm |

Format | LXD, DXF, PLT, AI, NC etc. |

Working environment | 0-45℃, Humidity ≤ 80%, non-condensing |

Equipment power | 8KW (not include laser generator and chiller) |

Power supply | Three phase 380V/50Hz or 60Hz |

Total weight | 3000Kg |

Overall size | 5010*2260*1900mm |