Details Product Parameters Samples Video

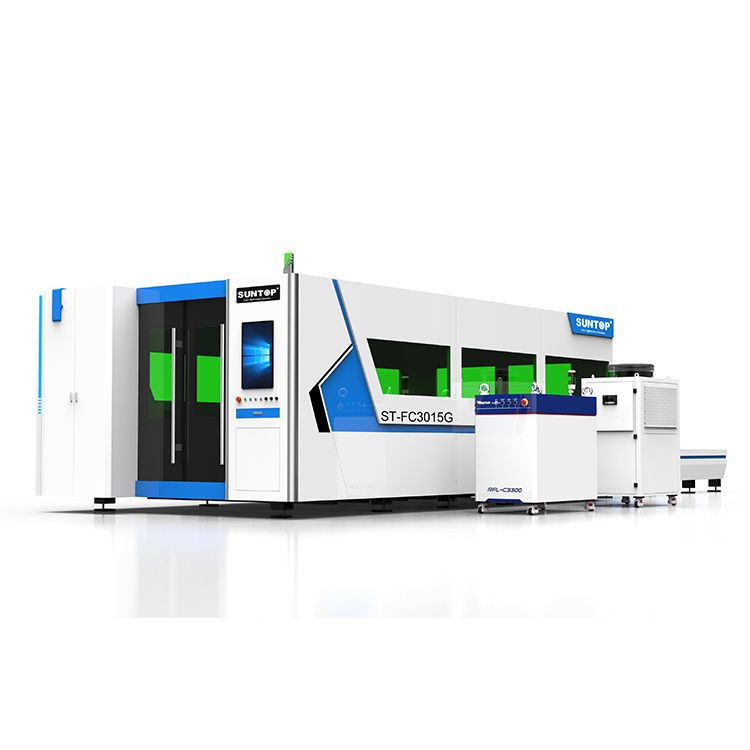

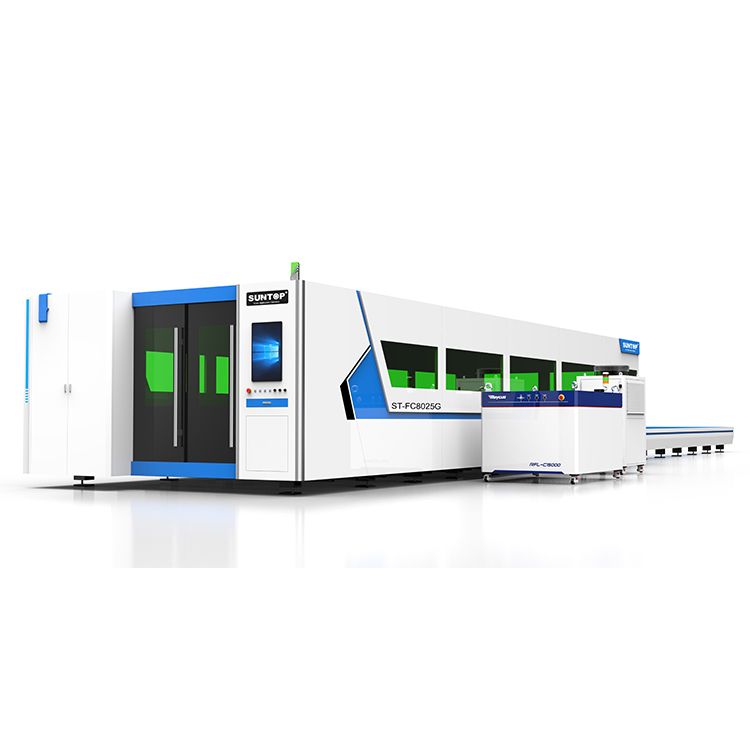

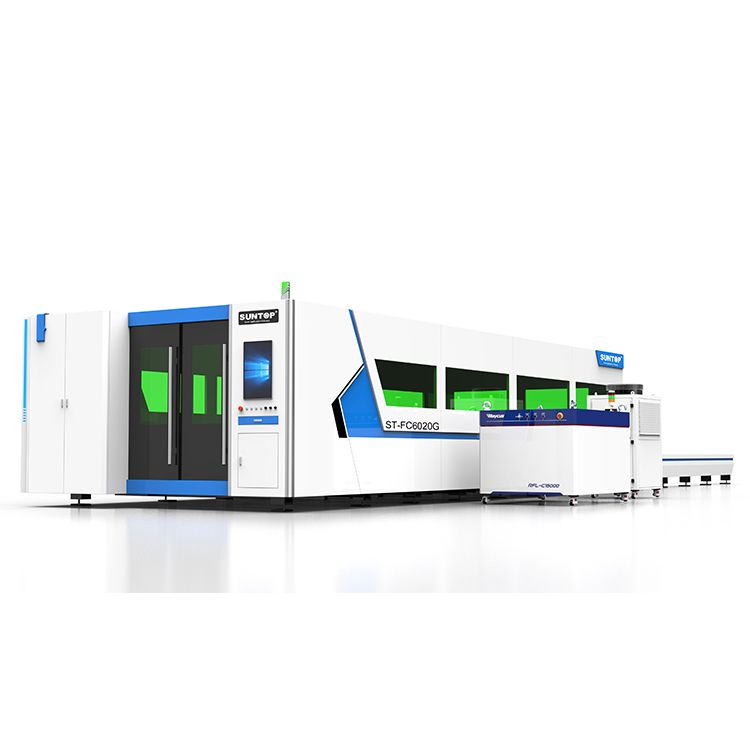

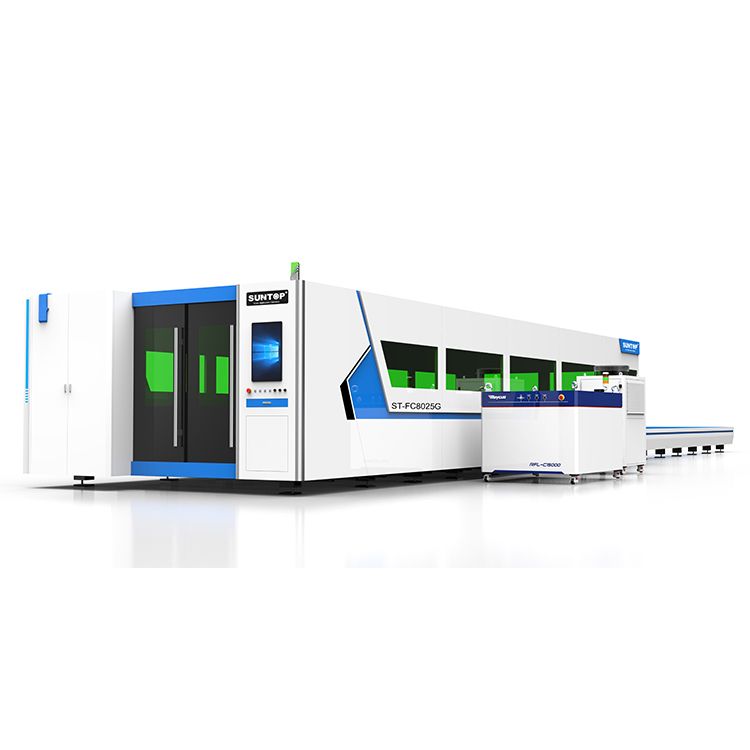

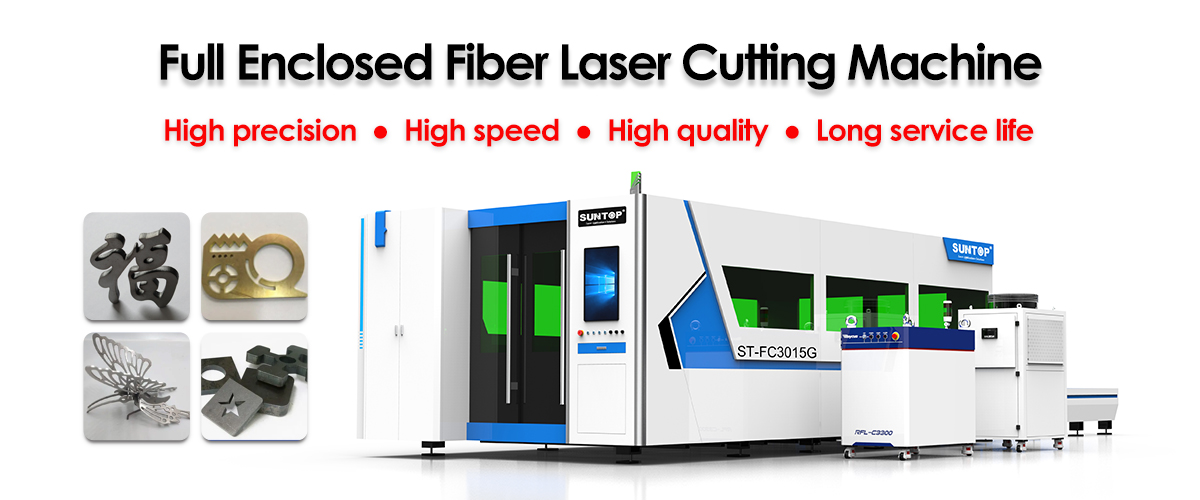

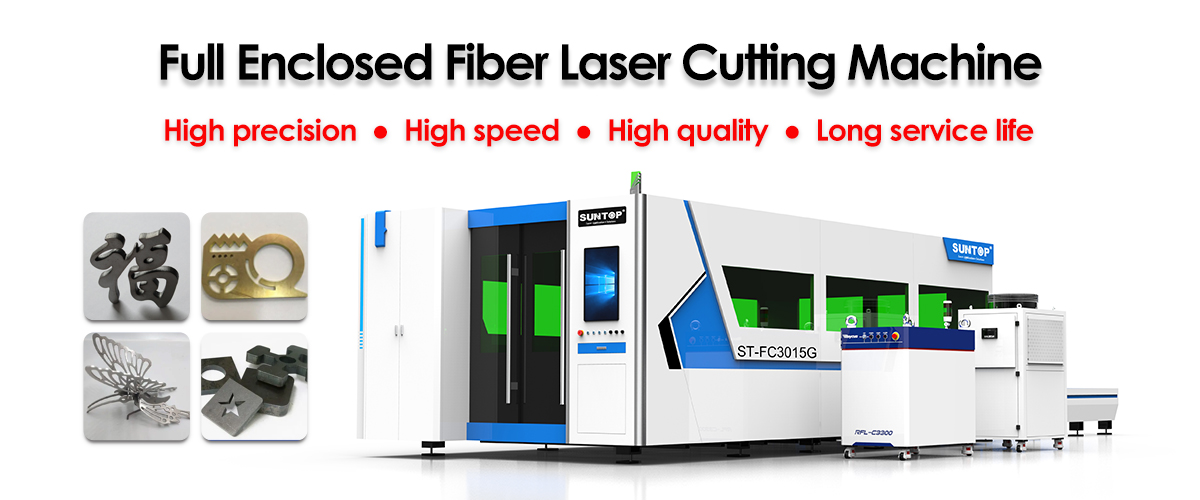

Full Enclosed Fiber Laser Cutter Machine Main Features

1, Our this fiber laser cutting machine with air conditioner room and dust isolation/automatically-tracking smoking extraction system, energy-saving and perfect smoke extracton effect. Because of all electrical parts and laser Generator are inside of the machine, so our this design and idea will keep parts working stably even 24 hours continued working from which prolong the lifetime of the machine's optical parts, electrical parts etc.

2, The mechanical transmission part has been tested and calibrated with laser interferometer for many times to ensure the our machine good and stable accuracy even after a few years of use, which is VERY important for end users.

3, Our machine tool is used integrated welding after annealing to eliminate stress, the process of cutting welding stress relief annealing—roughing—VSR—semi-finished-VSR-Finishing, a better solution due to welding and the stress arising from the processing, which greatly improve the stability of the machine, the common thickness range of structure metal profiles from 12-15mm which at least 20 years no deformation.

4, Monitor system, both the front table and the back table of the machine are equipped with cameras, which can effectively monitor the working status of the tables.

5, Configured with inductive RAYTOOLS aoto focus fiber laser cutting head and mirror to reach as much smaller focus spot as, more delicate lines can be cut, higher efficiency, better processing quality.

6, Optical fiber transmission, flexible processing, cutting quality at any point can be ensured.

7, Professional laser CNC control system (Cypcut cutting software), computer operation, more simple operation and multi-functions:

No. | Functions | Main Descriptions |

1 | Height following | Torch move up and down according to plate height |

2 | Power control | Laser power controlled according to slope |

3 | Reverse function | Reverse to execute NC program |

4 | Breakpoint return | Return to breakpoint after recovery |

5 | Multi piercing | Pulse, blasting, progress, high-speed |

6 | Lead line | Set lead line parameter |

7 | Auto edge-finding | Find cutting piece coordinate automatically |

8 | Leapfrog function | Leapfrog to improve cutting efficiency |

9 | Common line | Common line to improve the cutting efficiency |

10 | Marking function | Machine can do any shape laser engraving on plate |

11 | Nesting function | Software can array the cutting pieces automatically, it can save both the materials and the labor energy |

8, Compatible wth a variety of software, can design all kinds of graphics or text instant cutting, simple operation, flexible, convenient

9, With intelligent discharging function, material utilization rate is higher.

10, machine can be equipped wth Auto nesting function.

11, Machine can choose the famous brand IPG/RAYCUS/nLIGHT/TRUMPF laser Generator.

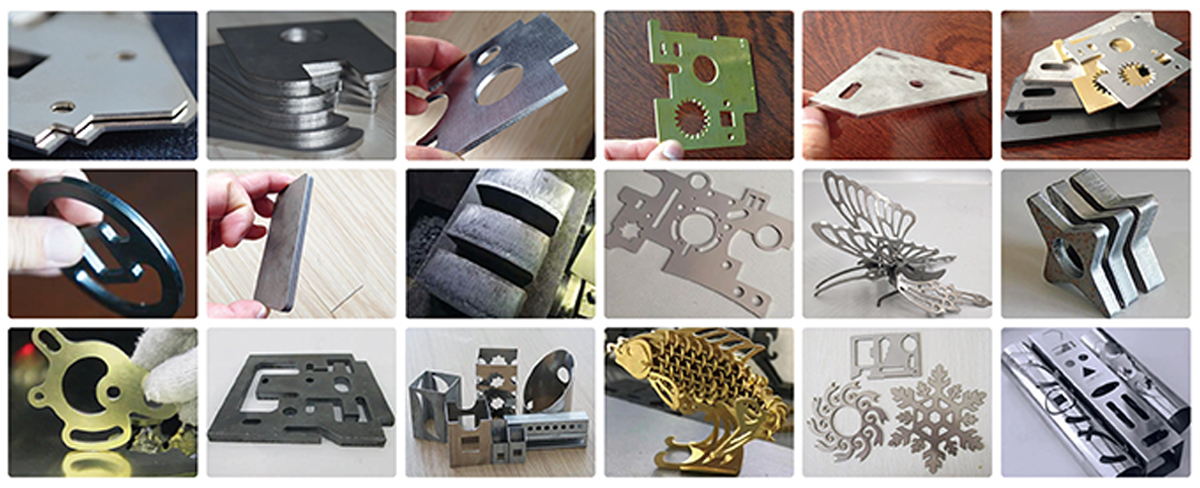

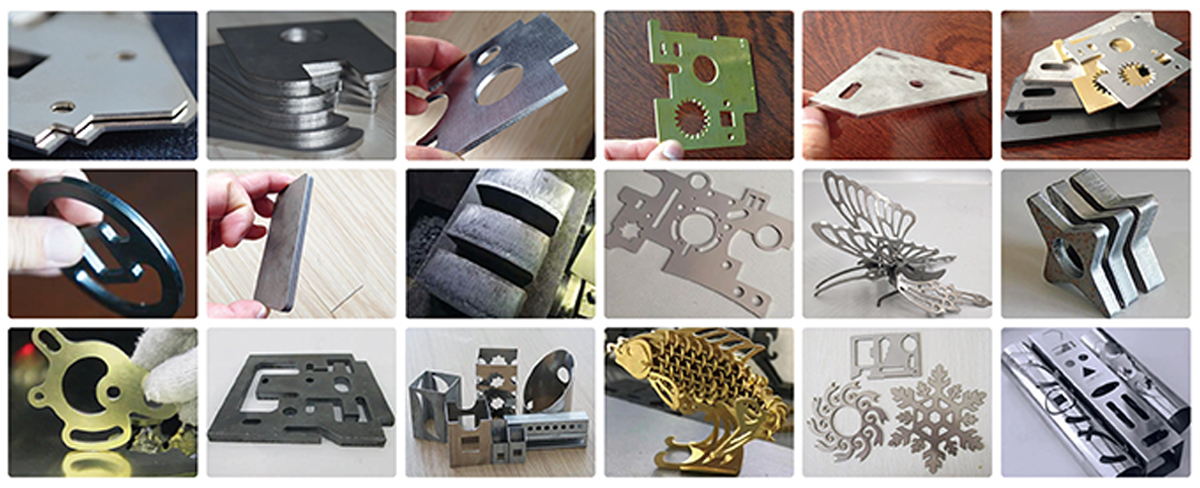

Fiber laser cutting machine the application materials

Steel metals processing, advertising sings production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, metal board, kettles, medical microelectronics, hardware, knife measuring tools and other metal processing industry.