Details Product Parameters Samples Video

Features of fiber laser scribing machine

● High configuration: Using imported fiber laser, the beam quality is better (standard basic mode), the slit is thinner, and the edge is flatter and smoother.

● Maintenance-free: The whole machine adopts international standard modular design, truly maintenance-free, uninterrupted continuous operation, and no replacement of consumable wearing parts.

●Easy to operate: The equipment integrates air-cooling settings, making the equipment smaller and easier to operate.

●Specialized control software: The control software specially designed for laser dicing machines is easy to operate and can display the dicing path in real time.

● High work efficiency: fast speed, improve work efficiency.

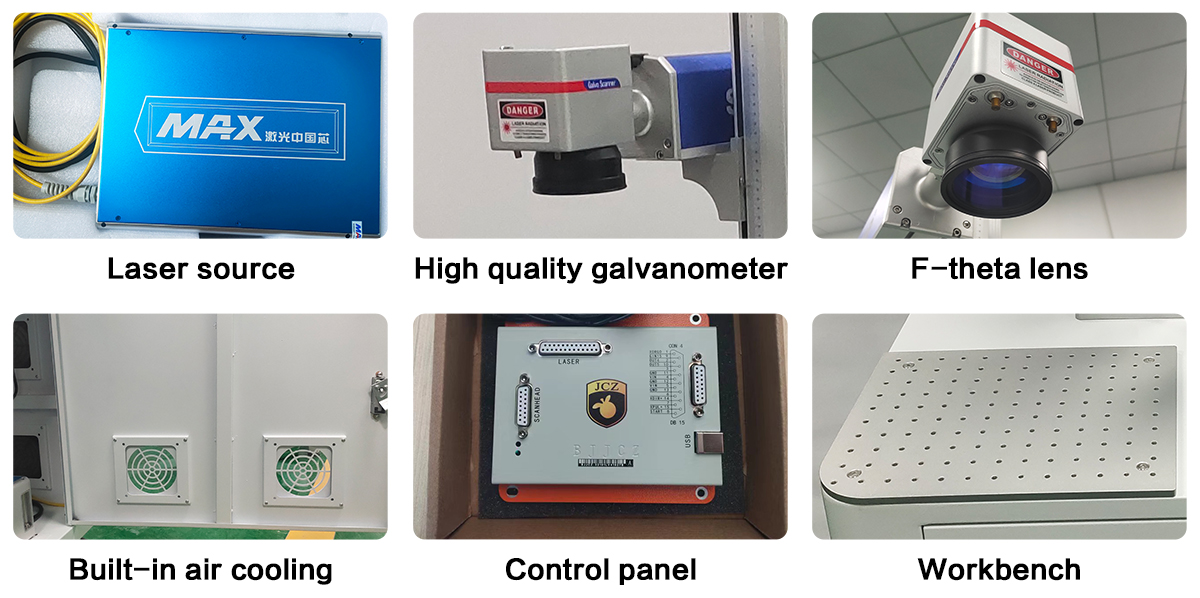

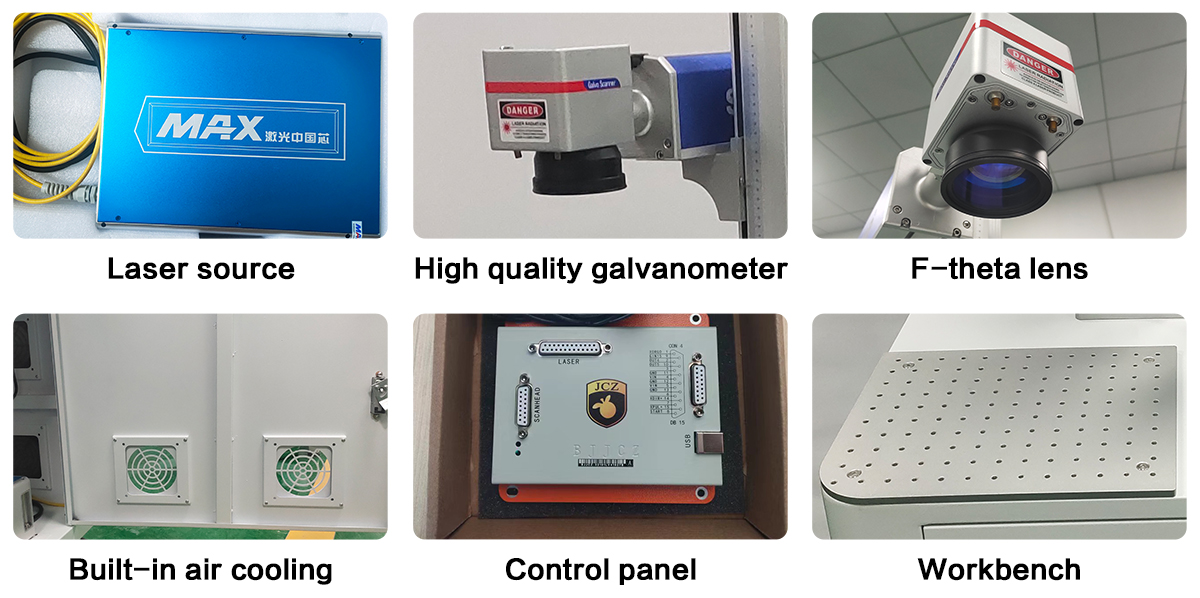

Details of fiber laser scribing machine

1. Laser

The core component is the laser, which is responsible for generating a high-power, high-stability laser beam, allowing the laser beam to perform marking operations with higher speed and accuracy.

2. Galvanometer system

Responsible for controlling the trajectory and direction of the laser beam. By precisely controlling the movement of the galvanometer system, rapid and precise marking of the laser beam on the material surface can be achieved.

3. Field lens

Used to diffuse the laser beam and form a certain spot size to adapt to marking areas of different sizes. By adjusting the focal length and angle of the field lens, precise control of the spot size can be achieved, thereby achieving efficient and high-quality marking effects.

4. Beam combiner

Used to combine the laser beam with red light to observe the accuracy of the mark position during the marking process. By overlapping the beam combiner and the laser beam, the optical path indication is achieved, allowing the operator to more intuitively observe the status and position during the marking process.

5. Red light indicator

It is used to indicate the position of the laser beam. The beam combiner and the laser beam are overlapped to achieve optical path indication. During the marking process, the red light indicator can help the operator quickly locate the marking position and improve marking efficiency.

6. Control software

It is the core control part, used to generate and edit marking patterns, and control various operating parameters of the fiber laser marking machine. Through control software, automated marking operations can be realized to improve production efficiency and quality.

Advantages of fiber laser scribing machine

1. Non-contact processing, no damage to materials, no pollution, energy saving and environmental protection.

2. Fiber laser does not need to adjust the laser light path, no maintenance.

3. High electro-optical conversion efficiency: electro-optical conversion efficiency can reach more than 28%, energy saving and power saving. Non-contact processing, no pollution, no noise, very environmentally friendly.

4. long service life of the laser, no problem to use 100,000 hours.

5. Omni-directional wheels and adjustable feet, easy to move. Reliable structure, low power consumption, flexible and convenient installation.

Application materials of fiber laser scribing machine

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of fiber laser scribing machine

Widely used in integrated circuit chips, computer accessories, industrial bearings, clocks, electronics and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military and other industries , and high-volume production line operations.

Parameters of fiber laser scribing machine

Model | ST-FL20B/ST-FL30B/ST-FL50B/ST-FL100B |

Laser power | 20W/30W/50W/100W (optional) |

Marking area | 110*110mm-600*600mm (depend on the actual laser power) |

Laser wavelength | 1064nm |

Working accuracy | ±0.002mm |

Marking Depth | 0-0.5mm |

Minimum font for marking | 0.15mm |

Minimum character | 0.2mm |

Marking speed | 0-7000mm/s |

Operating system | Win7 and Win10/32 bit and 64 bit |

Laser source | MAX Brand(Raycus can be choose) |

Repetition frequency | 20-100KHz |

Cooling mode | Air Cooling |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Environmental requirements | Temperature: 10-35℃, Humidity: 5-75% |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net weight/gross weight (KG) | 120KG / 150KG |

Machine dimension | 860*760*1130mm (L*W*H) |