Details Product Parameters Samples Video

Features of custom laser marking systems

1. Adopting built-in laser diode technology to avoid the effect of fiber jitter on the output laser.

2. The quality of UV beam is excellent enough to ensure the stability and reliability of mass production and meet the special manufacturing and processing requirements under harsh industrial conditions.

3. It is a cooled laser, which has very good and smooth marking effect on heat-sensitive plastic materials without causing any damage to the material surface.

4. Suntop fiber laser marking machine factory after strict aging test, the laser beam continuous 24 hours output, to ensure that the machine 100% stability.

5. Electro-optical conversion efficiency is very high, reaching more than 30%, low cost of use, power saving and energy saving.

6. High marking precision, fast speed, clear text pattern, uniformity, durability, low power consumption.

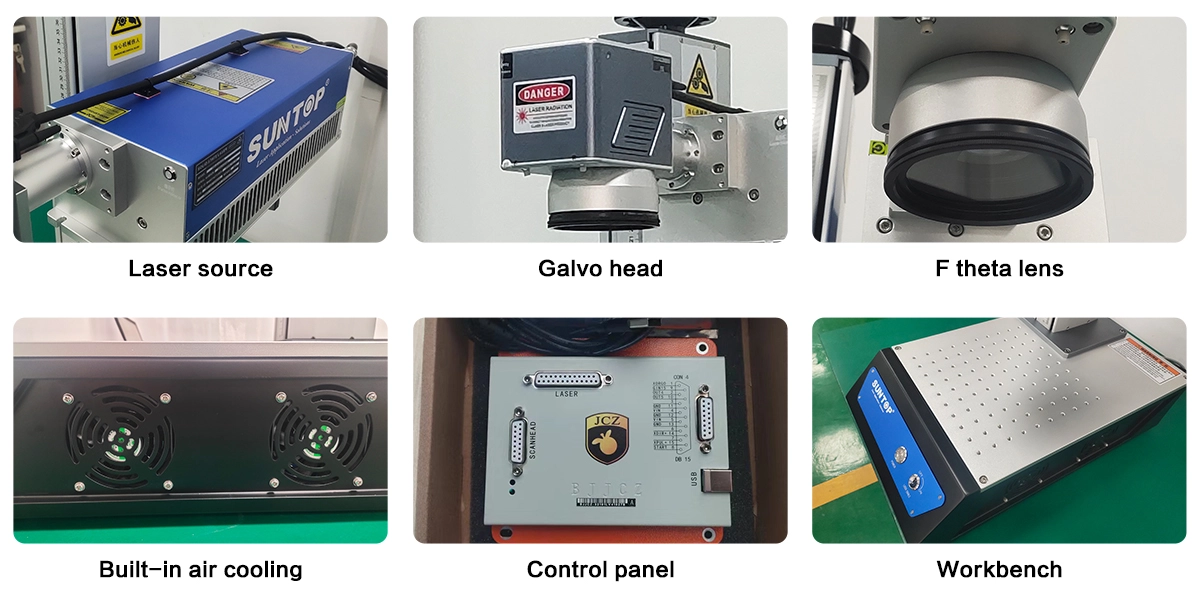

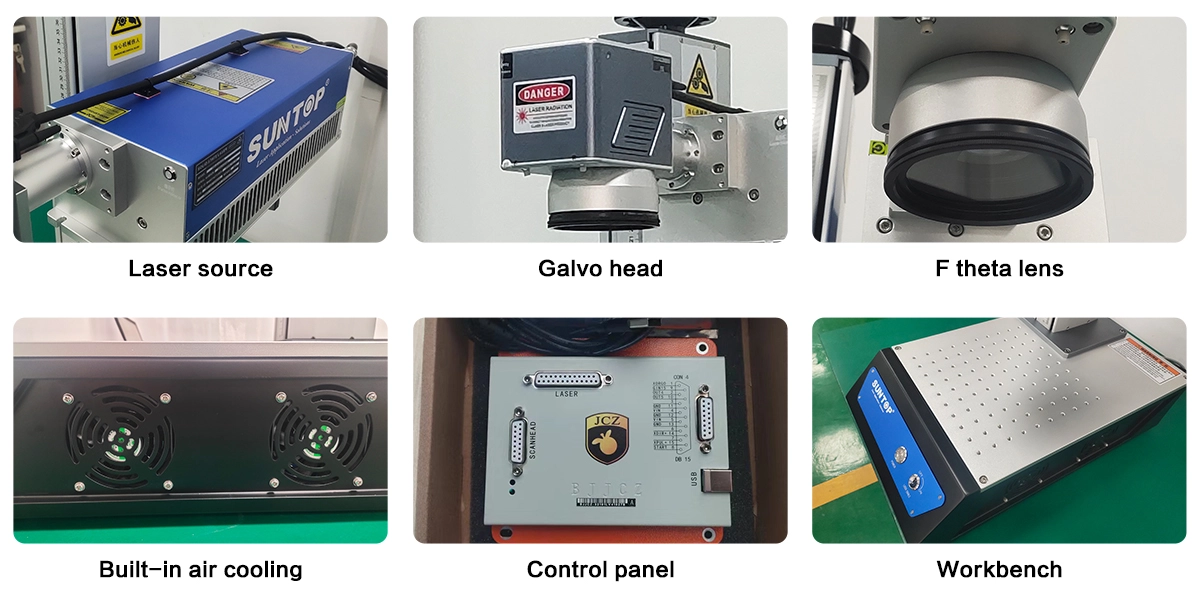

Details of custom laser marking systems

1. Laser

The core component is the laser, which is responsible for generating a high-power, highly stable laser beam, enabling the laser beam to perform marking operations at higher speeds and with greater precision.

2. Laser Scanning Mirror

Optical scanning oscillator is also the core component of the laser marking machine, mainly used in the rapid and accurate positioning of the beam, the performance of the oscillator determines the accuracy of the marking machine.

3. Focusing system

Focusing system will focus the parallel laser beam on one point, mainly using f-θ lens (also called field lens), different field lens focal length is different, marking effect and range is not the same, according to their own products and need to mark the range of optional field lens model.

4. laser power supply

Laser power supply input voltage of AC220V AC small machine with a switching power supply, easy to carry, emergency stops.

5. marking software

Laser processing system combined with computer numerical control technology, constitute a highly efficient automated processing equipment, can play a variety of text, patterns, symbols, one-dimensional code, two-dimensional code, etc., easy to use the software design marking pattern, change the marking content, to adapt to the modernization of the production of high-efficiency, fast-paced requirements.

6 computer control system

Is the whole laser marking machine control and command center, but also the carrier of software installation. Through the sound and light modulation system, galvanometer scanning system coordinated control to complete the workpiece marking processing.

Advantages of custom laser marking systems

● Personalized needs met: Customized laser marking systems can be designed and customized according to your specific needs and requirements. You can customize key system parameters such as power, marking speed, marking area and accuracy to suit different materials and applications.

● High precision and high quality: Customized laser marking systems usually have higher precision and better marking quality. By customizing according to material type and requirements, you can achieve more accurate, clear and long-lasting marking results to meet your high-quality marking needs.

● Versatility: Customized laser marking systems can be designed to be multi-functional. In addition to marking, they can also perform operations such as cutting, engraving, and surface treatment. You can choose suitable functions according to your needs and integrate them into a system to increase the diversity and application scope of the device.

● High efficiency and automation: Customized laser marking systems can be optimized according to your production needs to achieve higher work efficiency and production automation. For example, it can be integrated with automation equipment or production lines to achieve high-speed continuous marking and automated production processes.

● Reliability and stability: Customized laser marking systems are professionally designed and manufactured and generally have higher reliability and stability. Suppliers will select suitable lasers and core components based on your requirements and their expertise, and conduct strict quality control to ensure long-term stable operation of the system.

Application materials of custom laser marking systems

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry of custom laser marking systems

Especially suitable for the high-end market of ultra-fine processing, skin care cosmetics, medical drugs, food, silicon wafer micro-hole, blind hole processing, glass products, metal products, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Parameters of custom laser marking systems

Model | ST-UV03P | ST-UV05P |

Laser Power | 3W | 5W |

Max. marking range | 110*110mm | 150*150mm |

Output power | >3W@30KHZ | >5W@40KHZ |

Maximum pulse energy | 0.1MJ@30KHZ | 0.12MJ@40KHZ |

Pulse duration | <15NS@30KHZ | <18NS@40KHZ |

1/e2 beam diameter at output | 0.7mm | 0.8mm |

Laser Type | UV laser |

Laser source | GAIN (JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Water Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | all metal material and all non metal material |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 38KG / 48KG |

Packaging Dimension | 320mm*7549mm*668mm (L*W*H) |