1. Energy saving and environmental protection:

High-efficiency photoelectric conversion makes energy consumption lower, which helps enterprises reduce energy costs and reduce environmental burden.

2. Economical and efficient:

Long life and low maintenance cost enable users to achieve higher cost performance in long-term use.

3. High-precision processing:

Suitable for various fine processing needs, and can meet high requirements for product beauty and quality.

4. Wide range of applications:

Can process metals and non-metals, widely used in electronics, automobiles, medical devices and other industries.

5. User-friendliness:

Simple operation interface and convenient maintenance process allow users to quickly get started and reduce training time.

6. Quick response:

The laser emission time is short, suitable for high-frequency production environment, and improves production efficiency.

7. Strong anti-interference ability:

Can work normally in complex industrial environments and reduce equipment failures caused by external environment.

8. Customized service:

Provide customized solutions according to user needs to meet the requirements of specific materials or processing methods.

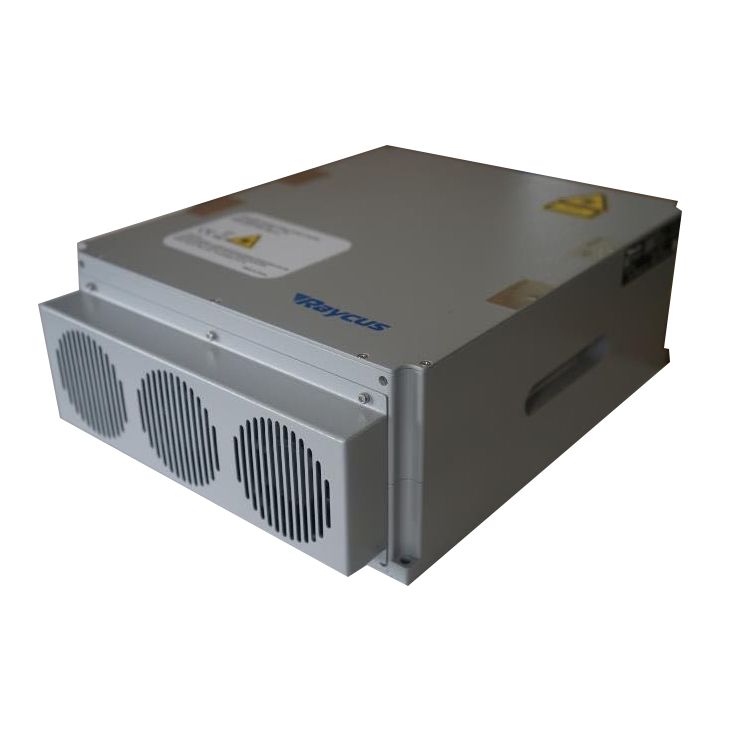

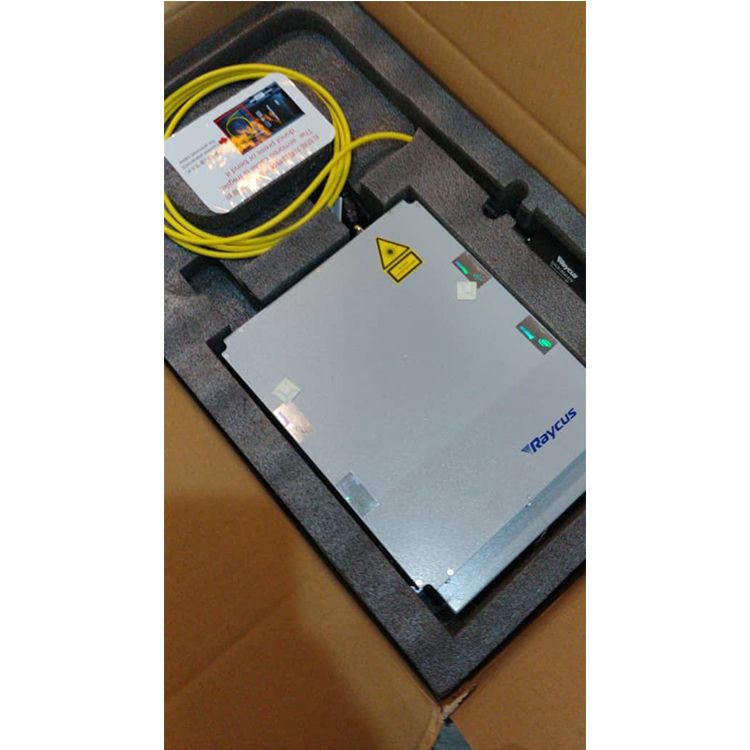

RAYCUS fiber laser generator provides excellent solutions for laser marking and processing with its high efficiency, long life, high-quality laser beam and wide range of applications. It is one of the indispensable equipment in modern manufacturing industry. Its flexibility and economy make it popular in the laser processing industry.