CCD vision laser marking machine is a combination of CCD vision technology and laser marking technology equipment, can realize fast and accurate positioning and marking, is widely used in various industries.

CCD vision laser marking machine introduction

Laser marking machine is the use of laser through the control system to quickly scan the surface of the product to leave an imprint, forming information. Laser marking machine using vision technology, equivalent to adding a pair of eyes to the laser machine. Using this pair of eyes, the laser machine can save manual placement, accurately identify the product to be marked, improve efficiency and save labor. Visual positioning laser marking machine is the product of the development of the times, is the result of the transformation of scientific and technological civilization.

Working principle of laser marking machine visual positioning

CCD vision laser marking machine using visual positioning principle, first develop a product template, determine the shape of the product, save as a standard template, normal processing when taking pictures, the computer quickly compare the template to compare the position of the location of the positioning, adjusted to process the product. This function can automatically identify the product characteristics of the product marking, in order to achieve positioning, small objects can also be accurately marked, the use of fixtures, reduce manual involvement, optimize work efficiency.

Laser marking CCD vision system

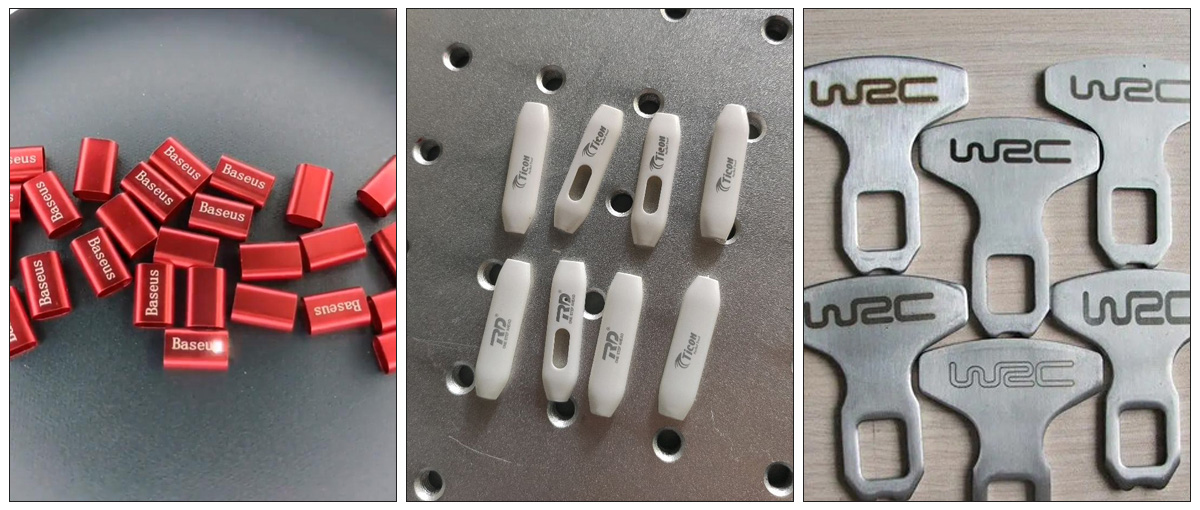

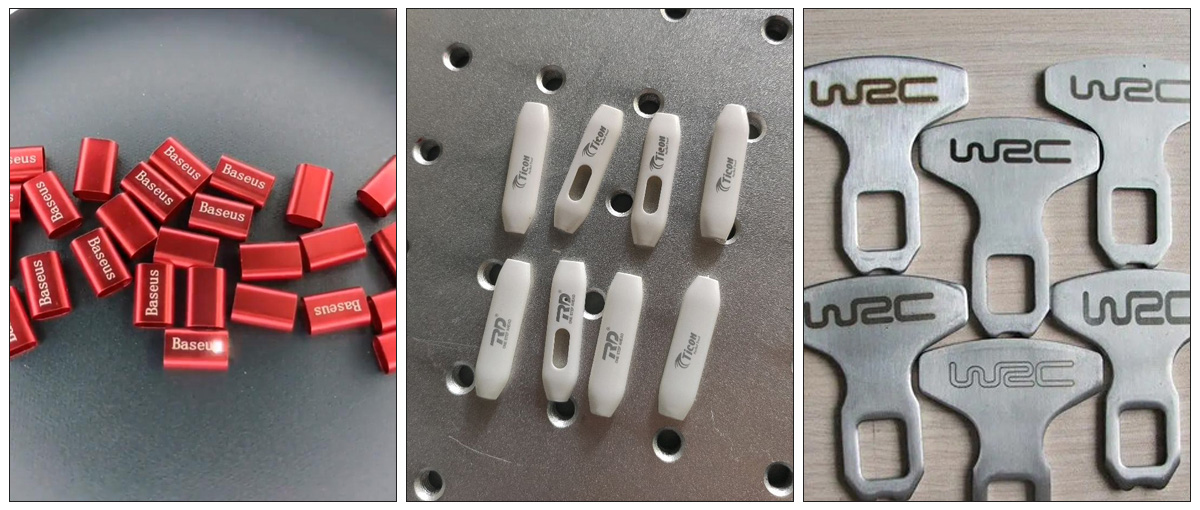

1. The automatic laser marker with CcD visual positioning is mainly for batch and irregular products.

2. lt can achieve high precision positioning and marking at any angle, number and position of materials.

3. Visual positioning solves the problems of difficult feeding, inaccurate positioning and slow speed caused by the difficulties in fixture design and manufacture.

4. lt can be solved by taking real-time pictures with an external camera and capturing the feature points.

5. With the cooperation of vibration disc, assembly line, XY platform and other components, unmanned and automated production can be achieved, greatly improving product quality and production efficiency.

Advantages of laser marking machine visual positioning

● Fast positioning marking

CCD vision laser marking machine captures the image of the target object in real time through CCD vision system and transmits it to the laser marking system to realize rapid positioning. This positioning method is not only fast, but also accurate, greatly improving production efficiency.

● High efficiency and precision

Laser marking technology has a very high precision, can be marked on the surface of various materials, and marking quality and durability, CCD vision laser marking machine combines this advantage, can realize efficient and accurate marking, in line with the needs of various industries.

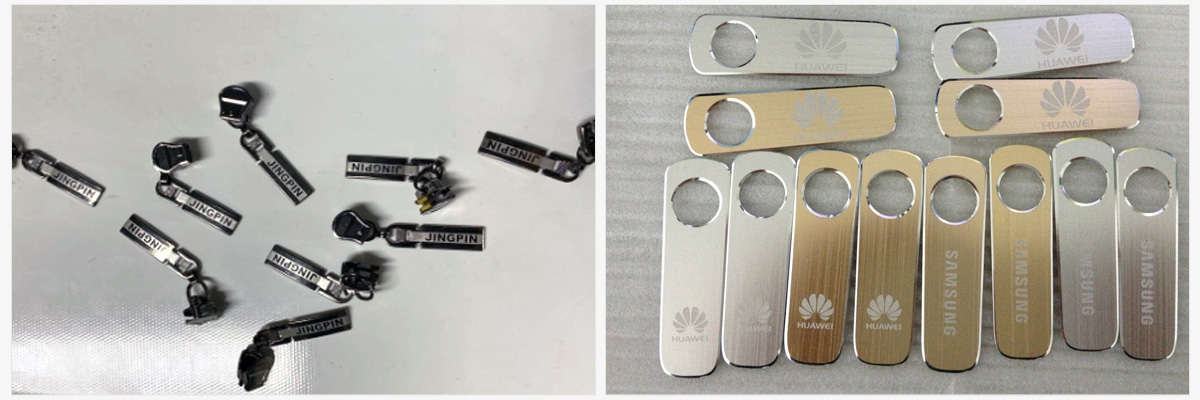

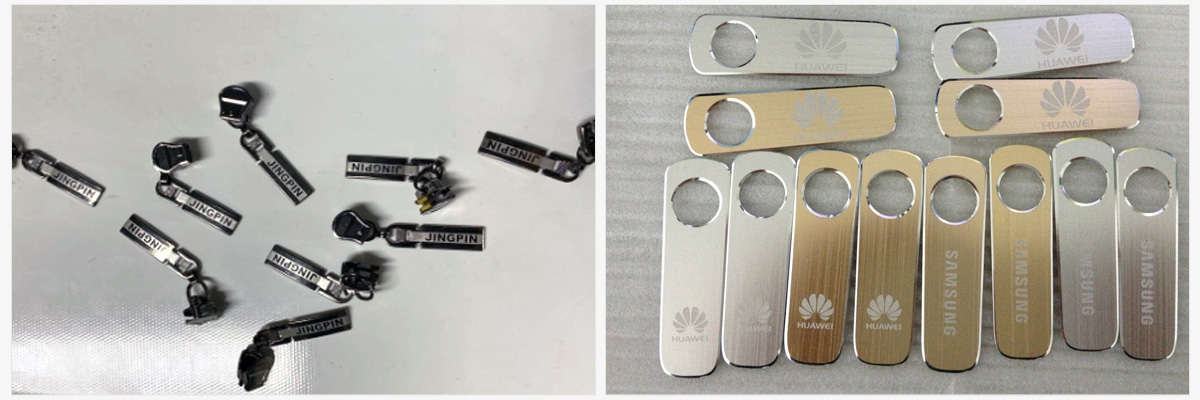

● Multi-industry applications

CCD vision laser marking machine is widely used in electronics, automotive, medical equipment, food packaging and other industries. Whether it is marking serial numbers, trademarks, production dates or 2D codes, it can be easily realized to meet the needs of different industries.

● Easy Operation

CCD vision laser marking machine is easy to operate, just set the relevant parameters, import the image to start marking. The operation interface is friendly, and the operator can get started without complicated training, which improves the production efficiency.

● Customizable design

According to customer requirements, CCD vision laser marking machine can be customized design, including marking range, marking speed, marking content and so on. Meet the individual needs of different customers and provide more professional solutions.

● Cost saving

CCD visual laser marking machine adopts laser as the marking tool, no consumables are needed, and the marking cost is low. At the same time, the efficient marking speed and accuracy also saves production costs, which is the ideal choice for enterprises to save costs.

CCD vision laser marking machine with fast positioning marking, high efficiency and accuracy and other characteristics, has become an indispensable and important equipment in the production of various industries. Its versatility, easy operation and cost-saving advantages bring higher production efficiency and better economic benefits for enterprises.