Details Product Parameters Samples Video

Features of laser marking stainless steel corrosion

1. The working speed is fast, which is 2-3 times that of the traditional one. The beam quality is good, the light spot is small, and the marking line width is extremely narrow, which can meet different marking needs.

2. The electro-optical conversion efficiency is very high, reaching more than 30%, the cost of use is low, and the power is saved. The power of the whole machine is only 600W/h.

3. The inherent fully enclosed flexible optical path makes the design of laser equipment more flexible

4. The laser beam is fine, the processing material consumption is small, and the processing heat-affected zone is small.

5. The scanning head has built-in 2 red lights for previewing the marking position, making it easier and more accurate to find the laser focus.

6. The auto focus function can be added to adjust the height of the laser focus according to the products of different heights on the workbench.

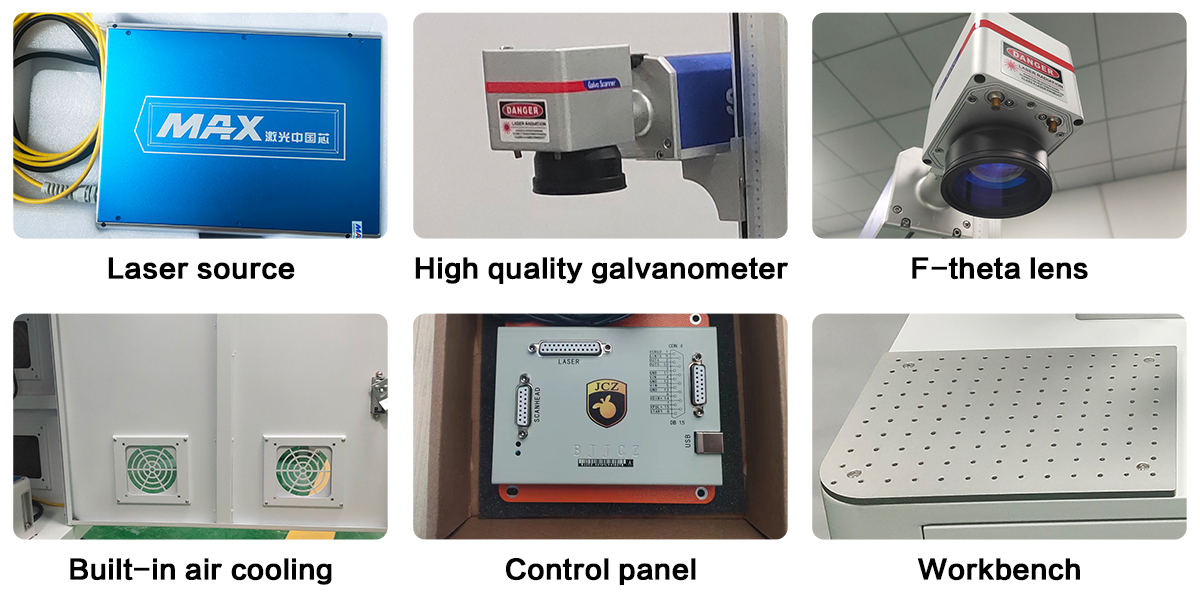

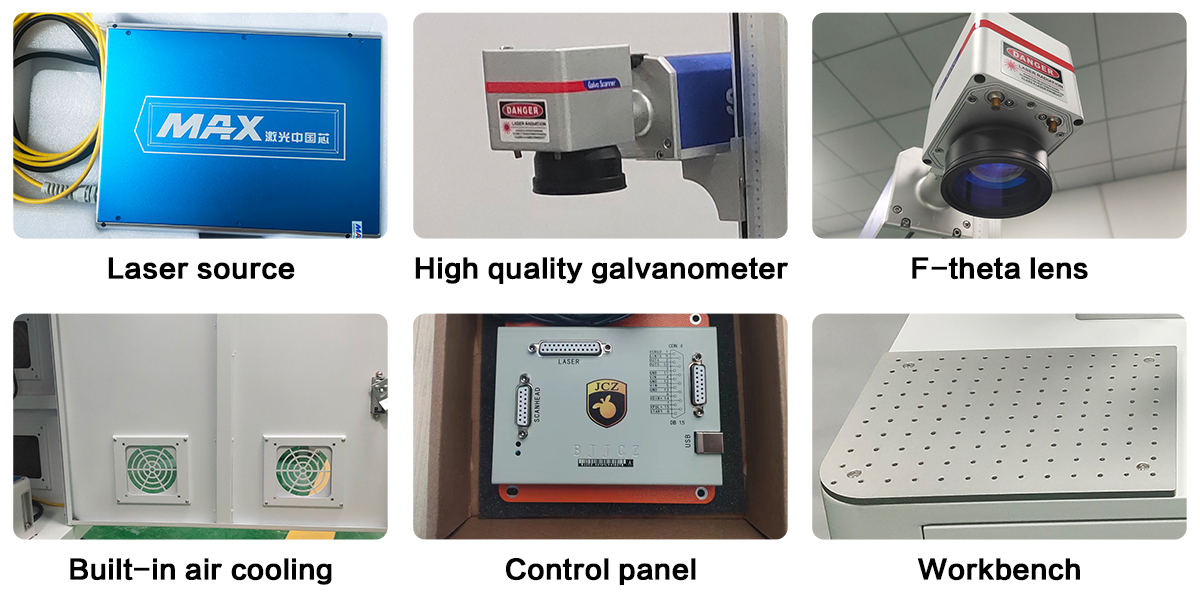

Details of laser marking stainless steel corrosion

1. Fiber laser

Using imported pulsed fiber laser, its output laser mode is good and its service life is long.

2. Galvanometer scanning system

The high-speed digital galvanometer scanning head has good running stability and high positioning accuracy, and can realize high-speed marking with high precision.

3. Focusing system

Focuses parallel laser beams on a single point. The f-theta lens is mainly used, and the fiber laser beam is focused to the surface of the workpiece through the lens, and the energy is sufficient.

4. Computer control system

It is the control and command center of the entire laser marking machine, and it is also the carrier of software installation to complete the marking process on the workpiece.

Advantages of laser marking stainless steel corrosion

● High-precision marking: Laser marking can achieve very fine marking effects, and can achieve clear and precise patterns, text, logos and other markings on the surface of stainless steel.

● Durability: The marks formed by laser marking on the surface of stainless steel have good durability and are not easy to wear, fade or fade. They are suitable for applications where marks need to be kept clear for a long time.

● Non-contact processing: Laser marking is a non-contact processing technology that will not cause indentation or damage to the stainless steel surface and maintain the quality and smoothness of the raw material surface.

● High efficiency: Laser marking has fast processing speed and high production efficiency, suitable for mass production or high-speed processing requirements.

● Diversified markings: Through laser marking technology, various styles, fonts, patterns and other markings can be realized on the surface of stainless steel to meet personalized and customized needs.

● Environmental protection: The laser marking process does not require the use of additional materials such as ink and solvent, and there is no waste water or exhaust gas emissions, which complies with environmental protection requirements.

Application materials of laser marking stainless steel corrosion

Suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminium, Steel, Iron Titanium etc, and can also mark on many nonmetal materials,such as ABS, Nylon, PES, PVC etc.

Application industry of laser marking stainless steel corrosion

Widely used in many industries such as machinery manufacturing, electronic appliances, optical communication devices, lithium-ion batteries, mobile phone parts, auto parts, medical equipment, precision machinery, integrated circuits, instrumentation, computer manufacturing, gold and silver jewelry, craft gifts, clothing and accessories.

Parameters of laser marking stainless steel corrosion

Model | ST-FL20B/ST-FL30B/ST-FL50B/ST-FL100B |

Laser power | 20W/30W/50W/100W (optional) |

Marking area | 110*110mm-600*600mm (depend on the actual laser power) |

Laser wavelength | 1064nm |

Working accuracy | ±0.002mm |

Marking Depth | 0-0.5mm |

Minimum font for marking | 0.15mm |

Minimum character | 0.2mm |

Marking speed | 0-7000mm/s |

Operating system | Win7 and Win10/32 bit and 64 bit |

Laser source | MAX Brand(Raycus can be choose) |

Repetition frequency | 20-100KHz |

Cooling mode | Air Cooling |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Environmental requirements | Temperature: 10-35℃, Humidity: 5-75% |

Working voltage | 220V±10% 50/60 Hz |

Applicable material | All metal (Stainless steel, Carbon steel, Brass,etc.) and some plastic(ABS, PVC,PES, ETC.) |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net weight/gross weight (KG) | 100KG / 115KG |

Machine dimension | 860*760*1130mm (L*W*H) |