1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What is a handheld laser welder?

A handheld laser welder is a welding device that uses a laser beam as a welding heat source and is suitable for a variety of metal materials. It is designed to be portable, and the operator can freely control the welding process, which is suitable for on-site operations and welding of complex structures.

6. What safety precautions should be taken when operating a handheld laser welder?

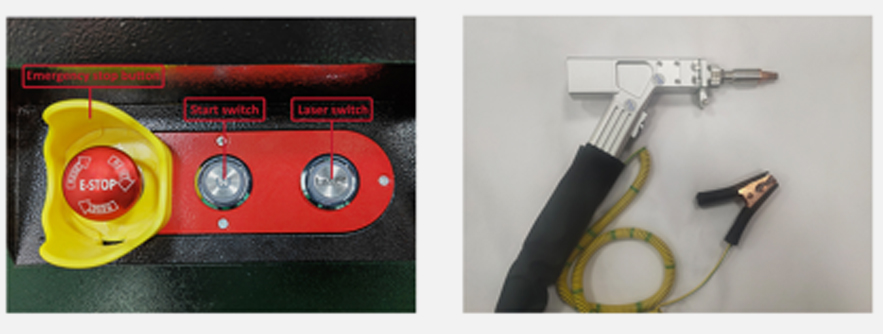

When operating a handheld laser welder, the following safety precautions should be taken:

Wear appropriate protective glasses to prevent laser radiation.

Ensure that the work area is well ventilated to reduce the accumulation of harmful gases.

Use welding gloves to protect your hands from heat and molten metal.

Ensure that various electrical equipment works properly to avoid leakage.

7. How thick is the metal material suitable for a handheld laser welder?

The handheld laser welder is suitable for welding metal materials with a thickness ranging from 0.5-8mm (single time), and the specific thickness depends on the equipment model and settings. The manufacturer usually provides detailed technical parameters and recommended ranges.

8. Does the handheld laser welder require special maintenance?

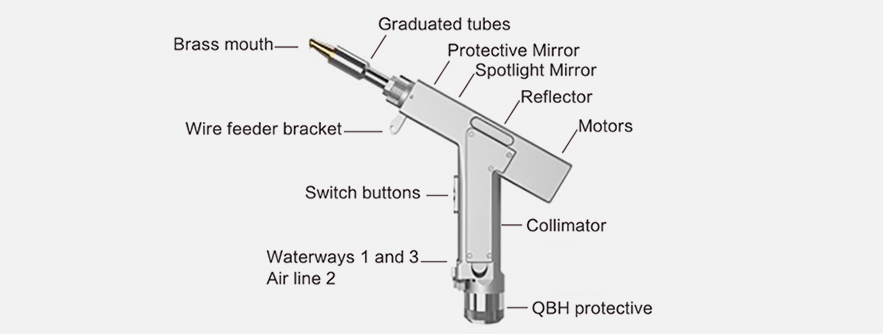

The handheld laser welder is relatively simple and easy to use, and the maintenance requirements are also low. It is necessary to regularly check key components such as optical fiber, laser and cooling system, and keep the equipment clean and ventilated. In addition, the equipment should be calibrated regularly to ensure welding quality.

9. How difficult is the operation of a handheld laser welding machine?

The handheld laser welding machine is designed to be user-friendly and relatively simple to operate. However, for beginners, it is recommended to receive proper training to familiarize themselves with the functions of the equipment and welding techniques to ensure welding quality and safety.

10. How much does handheld laser welding cost?

The initial investment of a handheld laser welding machine is relatively high, but due to its high efficiency and low maintenance cost, it can significantly reduce the overall welding cost in the long run, including material waste, heating time and subsequent processing costs.

11. Can a handheld laser welding machine be used in combination with other welding technologies?

Yes, a handheld laser welding machine can be used in combination with other welding technologies (such as TIG, MIG, etc.) to meet specific welding needs. This diversity makes the production process more flexible and efficient.

12. How to choose a suitable handheld laser welding machine?

When choosing a handheld laser welder, you should consider the following factors:

Welding material type and thickness

Welding speed requirements

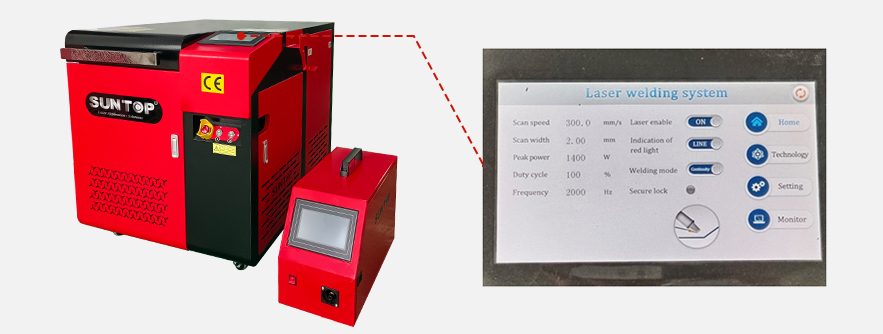

Equipment power and laser type

Operating environment and space

Safety and maintenance requirements

Budget and return on investment