Laser cleaning machine is a kind of equipment that uses laser technology to efficiently and accurately remove surface pollutants and dirt. It is widely used in many industries. The following are the main industries where laser cleaning machines are applied:

1. Manufacturing

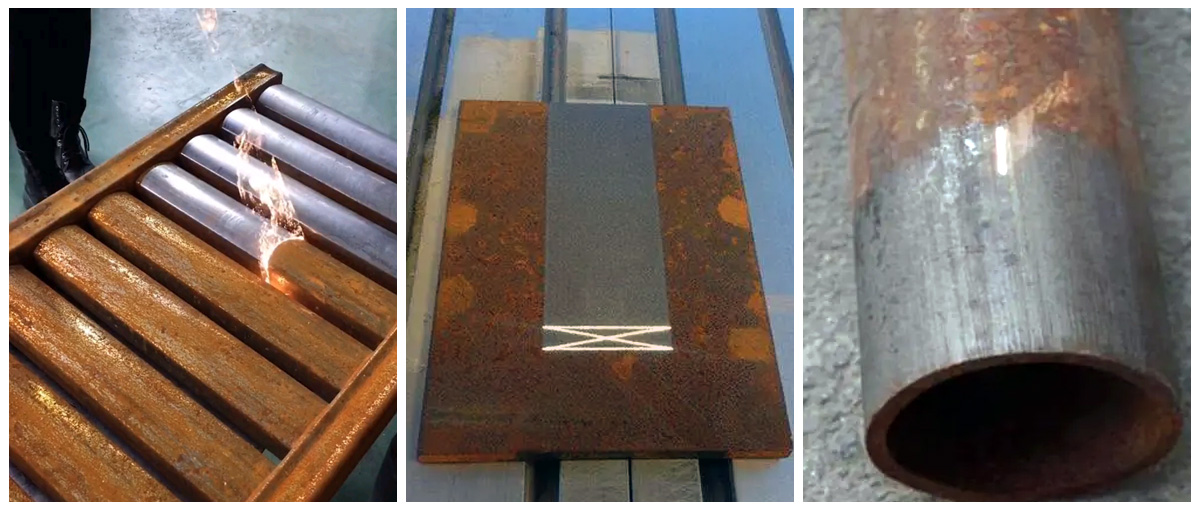

Metal processing: used to remove oil, rust, oxide layer and welding residues from metal surfaces to improve the quality of workpieces.

Mold cleaning: clean plastic, dust and residues on the surface of molds to extend the service life of molds.

2. Automobile industry

Engine and component cleaning: used to remove oil and carbon deposits on engine parts to improve engine performance.

Car body surface treatment: clean old paint, rust and dirt, prepare for painting or other subsequent treatment.

3. Aerospace

Aircraft maintenance: clean aircraft shells and engine parts, remove corrosion, oil, etc. to improve safety.

Spacecraft component cleaning: ensure the cleanliness of spacecraft surfaces and components, and remove any contaminants that may affect performance.

4. Electronics and electrical

Printed circuit board (PCB) cleaning: remove welding residues and oil to ensure the stability and reliability of circuit boards.

Electronic component cleaning: clean components in the electrical industry to maintain their good electrical properties.

5. Shipbuilding and marine engineering

Hull cleaning: remove marine organisms, dirt and rust from the surface of the hull to maintain the performance and appearance of the ship.

Marine equipment maintenance: clean offshore platforms and equipment to ensure efficient operation.

6. Building and construction

Concrete and component cleaning: remove dirt, paint, etc. from the surface of building materials to prepare for subsequent construction.

Steel structure cleaning: clean rust and pollutants on steel structures.

7. Environmental protection

Waste disposal: remove oil and scale from industrial equipment and pipelines

Environmental protection: reduce the use of chemical cleaning agents and meet environmental protection requirements

8. Cultural relics protection

Cleaning of antiques and artworks: remove dust and pollution from the surface of cultural relics to protect the integrity of cultural relics.

Museum exhibit maintenance: ensure that exhibits are kept in the best condition during the display.

The high efficiency, environmental protection and non-destructive characteristics of laser cleaning machines have gradually replaced traditional cleaning methods in the field of industrial cleaning, and the scope of application is expanding. With the development of technology, the application of laser cleaning in all walks of life will become more popular. Click here to contact Suntop Laser today for a free laser cleaning test.