|

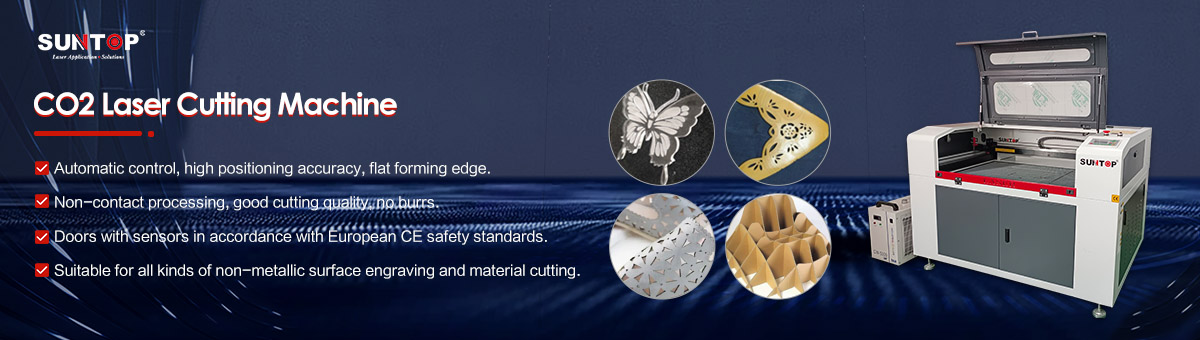

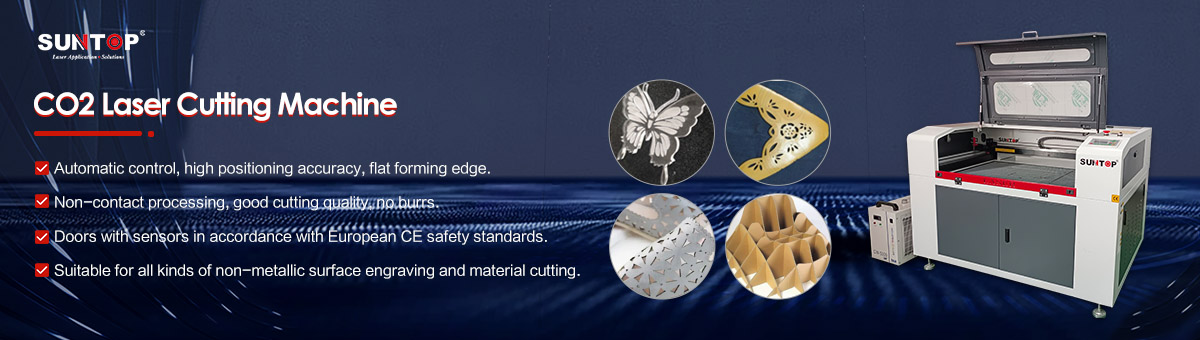

Advantages of CO2 Laser Cutting Machine

1. High precision:

CO2 laser cutting machines are able to achieve very high cutting accuracy, suitable for complex patterns and small parts that require fine processing.

2. Excellent cutting quality:

Due to the focusing ability of the laser beam, CO2 laser cutting achieves smooth and neat cutting edges, reducing the need for post-processing.

3. Fast cutting speed:

When it comes to cutting thin materials, CO2 laser cutting machines generally have faster cutting speeds, which improves production efficiency.

4. Contactless cutting:

Laser cutting is a contactless process that does not exert mechanical pressure on the material, thus reducing material deformation and damage.

5. High degree of automation:

Equipped with a control system that supports automated operation, it can automatically complete complex cutting tasks and improve production efficiency.

6. Wide range of cutting thickness:

Although there are some limitations in cutting thick materials, CO2 laser cutting machines are still able to handle a wide range of materials in thickness, from thin sheets to medium thickness materials.

7. Easy to process complex shapes:

Laser cutting machines can easily handle complex geometries and fine cutting paths, making them ideal for making complex patterns or crafts.

8. Small heat-affected zone:

The heat-affected zone generated by laser cutting is small, which can reduce thermal deformation and thermal damage of materials and maintain material properties.

9. Environmental protection:

The laser cutting process generates relatively little waste, and does not require the use of large amounts of cutting fluid and lubricants, which is relatively environmentally friendly.

10. Low maintenance requirements:

Although the initial investment is high, the maintenance frequency and cost of CO2 laser cutting machines are relatively low if used and maintained correctly.

|

Disadvantages of CO2 Laser Cutting Machine

1. Higher initial investment cost:

The initial investment in CO2 laser cutting machine is high, including the cost of equipment purchase, maintenance and laser. In addition, laser consumables and power consumption may also add to the operating costs.

2. Absorbability of CO2 laser:

CO2 laser has a long wavelength and has a low absorption rate for metal materials. In this case, metal cutting requires other laser types (e.g. fiber laser).

3. Limited ability to cut thick materials:

Although CO2 laser cutter is suitable for cutting thin materials, it has relatively weak cutting ability for thick metal materials.

4. Cutting speed is affected by material and thickness:

Although the cutting speed is faster, the efficiency of cutting for different materials and thicknesses varies greatly, and certain materials may be cut slower, resulting in lower productivity.

5. Laser tube life:

CO2 laser tubes have a limited service life, generally between a few thousand and tens of thousands of hours, however, as the use of time grows, the laser output power will decline and the laser tube may need to be replaced, which will increase the long-term operating costs of the enterprise.

CO2 laser cutting machines have performed well in many industries due to their high precision, fast speed and wide material applicability. However, problems such as high initial investment and limited ability to cut thick materials have also limited their application to a certain extent. Therefore, when choosing a laser cutting machine, you should fully consider your actual needs and budget to make the best choice. Click here to contact Suntop to recommend a suitable CO2 laser cutting machine for you.