In laser cleaning technology, understanding the characteristics of the material being cleaned is crucial to optimizing the cleaning effect. This includes factors such as surface material, type of dirt, and surface roughness.

1. Surface material

Different materials react very differently to laser cleaning technology. For example:

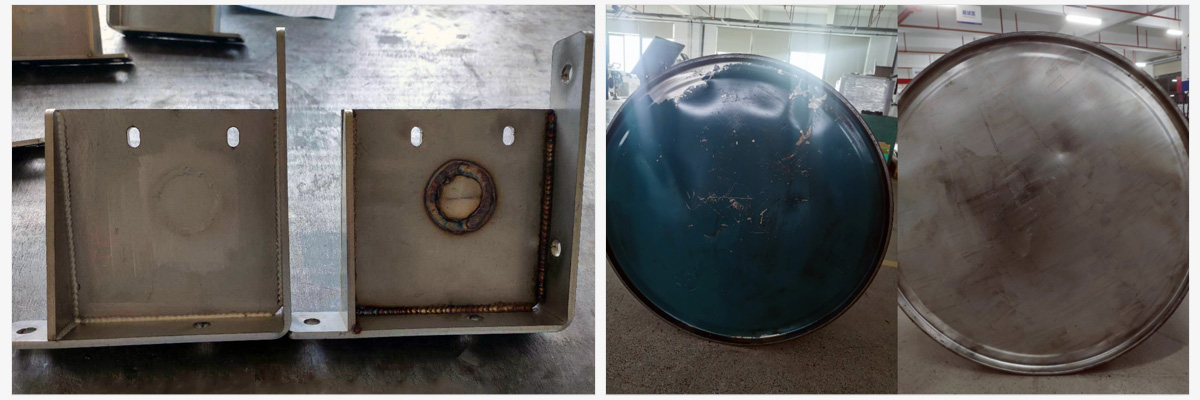

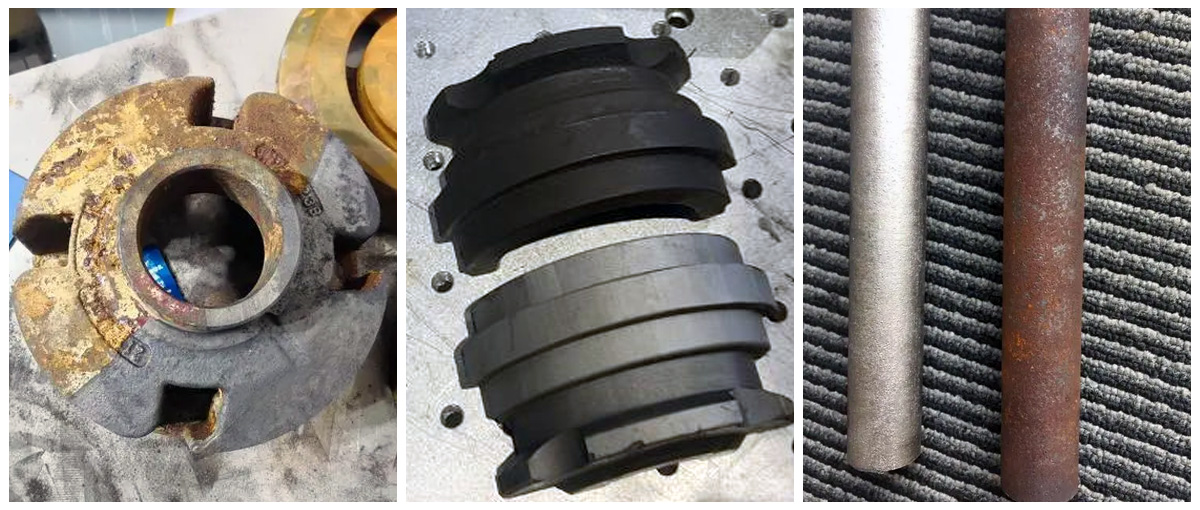

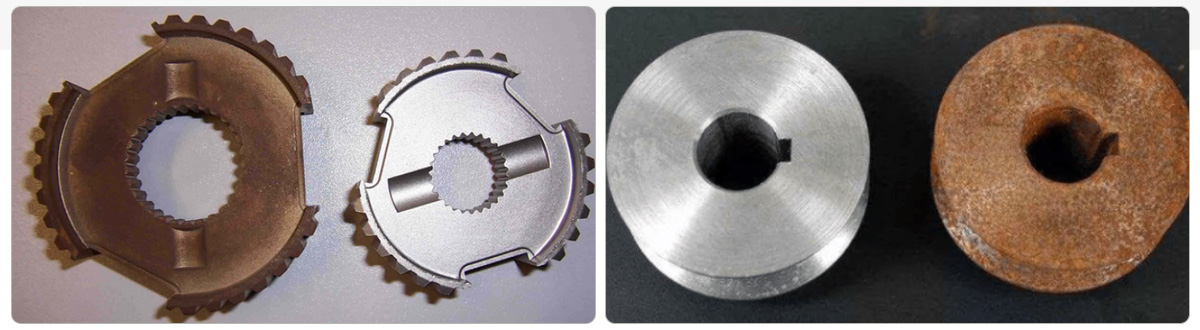

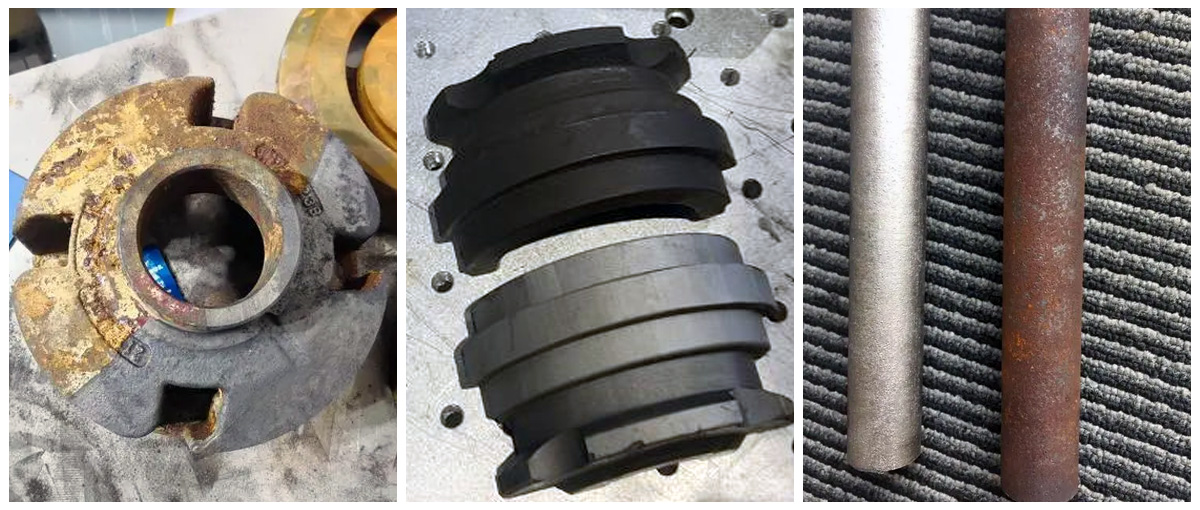

Metals: Metal materials (such as steel, aluminum, copper, etc.) have different absorption characteristics for lasers. Generally speaking, the use of 1064 nm wavelength lasers for metal cleaning works well because most metals can effectively absorb laser energy at this wavelength, thereby achieving rapid decontamination. Oxide layers and rust on metal surfaces are usually easier to remove, but care must be taken to avoid thermal damage to the substrate during processing.

Coatings: Coating materials (such as paint, plastic coatings, etc.) generally have low thermal conductivity and different absorption characteristics. Some coatings may require the selection of different wavelengths of lasers (such as 355 nm wavelength lasers) to ensure effective stripping, and it is important to distinguish the thickness of the coating. Excessive power may cause damage to the substrate, so be careful when selecting parameters.

Composites: Composite materials are often made of a combination of multiple materials, so the characteristics of different components need to be considered comprehensively. When cleaning, different laser parameters or segmented cleaning may be required for different components to achieve the best results.

2. Dirt type

The type of dirt has a significant impact on the efficiency of laser cleaning. Different types of dirt may require different laser parameters to effectively remove:

Oil: Oil is generally composed of hydrocarbons. Lasers can effectively decompose oil through thermal effects. Selecting the appropriate laser power and wavelength can quickly evaporate the oil without damaging the substrate.

Rust: Metal rust is usually iron oxide, and laser cleaning can effectively destroy its structure. High-power lasers can quickly heat up and peel off rust, ensuring that the metal surface restores its original gloss after cleaning. Different types of rust (pitting, thin rust, etc.) also require cleaning parameters to be adjusted according to their specific conditions.

Coating: Different coating materials (such as polyester, epoxy resin, etc.) react differently to lasers. When cleaning, consider the thickness and composition of the coating, and select the laser wavelength and power appropriately to ensure effective removal without damaging the substrate.

3. Surface roughness

Surface roughness is another important factor affecting the efficiency of laser cleaning. Rougher surfaces usually require more energy to achieve the same cleaning effect due to their larger effective contact area.

Influence mechanism: When the surface roughness is high, the laser is not distributed as evenly on the surface as on a smooth surface, which may cause some areas to overheat while other parts fail to reach the energy density required for cleaning. This requires that when setting the laser parameters, the power and scanning speed should be adjusted appropriately to ensure that each area can be fully cleaned.

Treatment method: For micron-level roughness left after surface processing, multiple scans or an increase in the laser spot diameter may be required to increase the contact area. For smooth surfaces, laser cleaning can be more efficient because no oil or impurities will remain after treatment.

Comprehensive consideration: In actual cleaning, the thickness of the material, the molding process, and the subsequent processing methods must also be considered, so that the advantages of laser cleaning can be fully utilized to improve the cleaning efficiency and effect.

Selecting appropriate laser parameters, understanding material properties, and dirt types can significantly optimize the efficiency of laser cleaning to meet the needs of different industrial applications. Click here for more information now