Product parameters Samples Video

SUNTOP sheet metal and tube fiber laser cutting machine main features

※, We adopted the 3rd Generation Aviation Aluminum Gantry, It is manufactured with aerospace standards and formed by 4300 Tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

※, One machine two cutting functions from which cost-saving:

ST-FC3015R fiber laser cutting machine can not only cut metal plates, but also different kinds of metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity for end users.

※, Our laser cutting machine tool is used integrated welding after annealing to eliminate stress, the process of cutting welding stress relief annealing—roughing—VSR—semi-finished-VSR-Finishing, a better solution due to welding and the stress arising from the processing, which greatly improve the stability of the machine, the common thickness range of structure metal profiles from 12-15mm which at least 20 years no deformation.

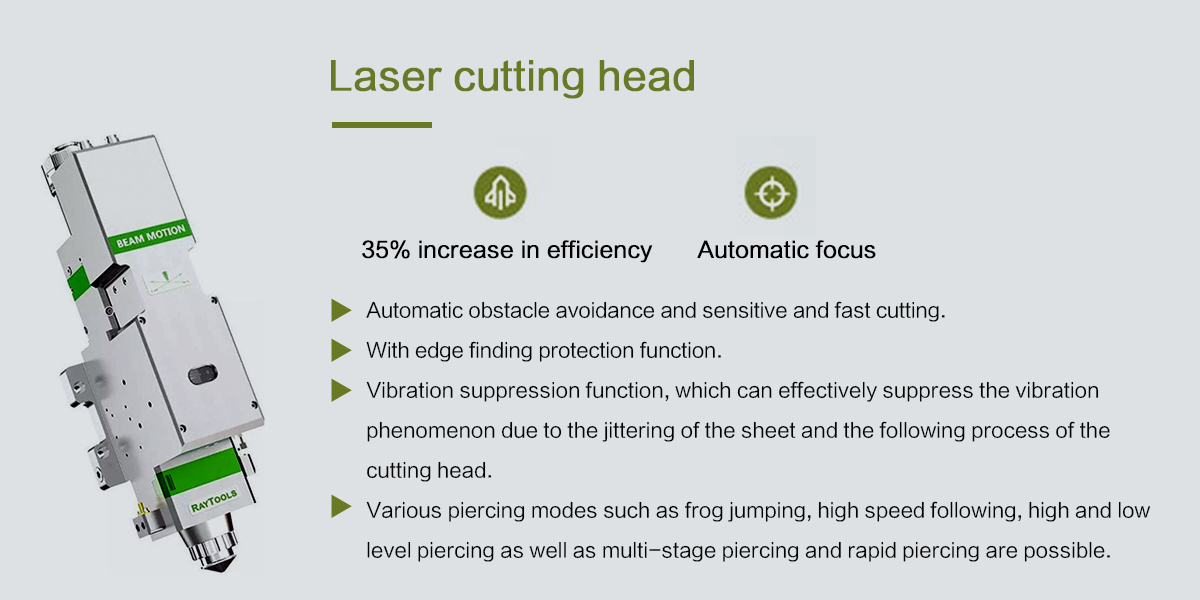

※, Advanced swiss RAYTOOLS fiber laser cutting head and CYPCUT control system

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

-Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

-Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

※, The laser Generator adopt the famous top brand in the world:

※, SUNTOP Tube and sheet metals fiber laser cutting machine's transmission and Precision

German Tech Quality

Suntop fiber laser cutting machines are equipped with German Atlanta or YYC gear and rack, Japanese Yaskawa motor and Japan SHIMPO reducer. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 10 years.

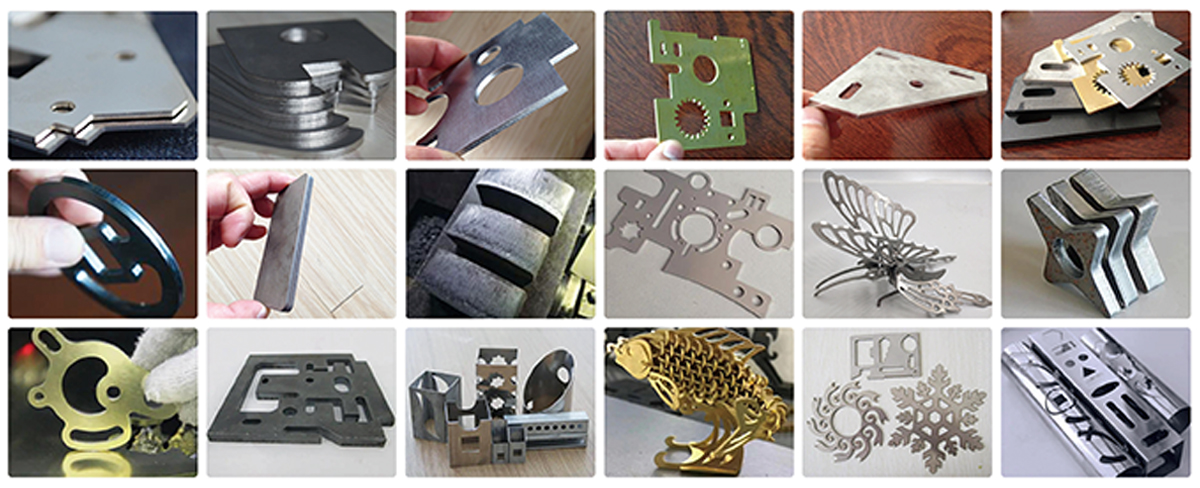

The tube and sheet metal CNC laser cutting machine application industries:

Steel metals processing, advertising sings production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, metal board, kettles, medical microelectronics, hardware, knife measuring tools, petroleum and pipe material, fitness equipment and other pipe material mainly mechanical processing, automotive manufacturing, machine cabinet and other board materials mainly mechanical processing, etc. and other metal and tubes processing industry.

The tube and sheet metal CNC laser metal cutting machine application materials:

Stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, steel, various alloy plate, rare metals and other kinds of metals.