Jewelry spot laser welding machine the introduction

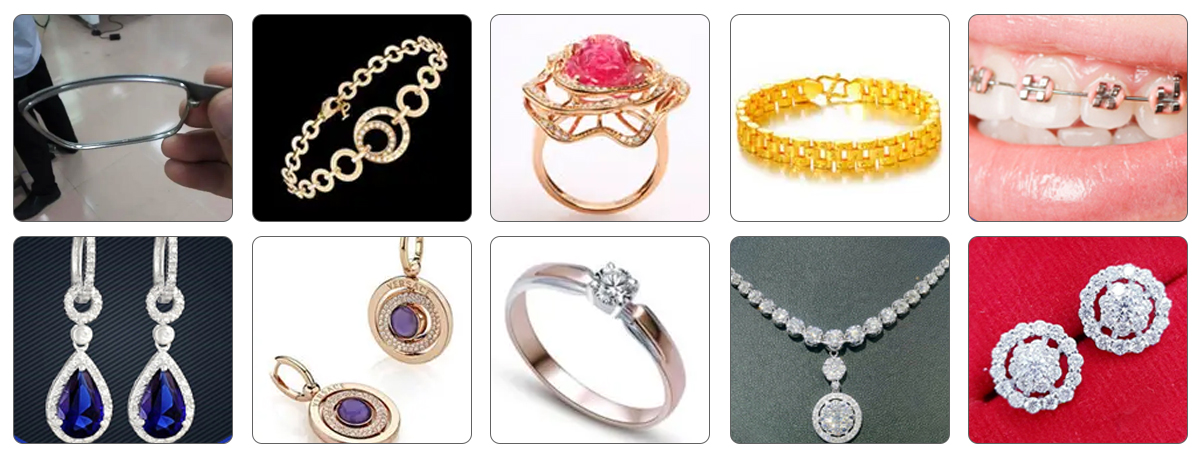

This machine is specially designed for jewelry and other small metal products spot laser welding, mainly used in spot welding of various metals.

Laser spot welding is an important aspect of laser material processing technology, one of the spot-welding process is thermal conduction, i.e. the laser radiation heating surface, the surface heat to the internal diffusion through heat conduction, by controlling the width of laser pulse, energy, peak power and repeating frequency, parameters such as melting of components, to form specific molten pool.

Due to its unique advantages, it has been successfully used in gold and silver jewelry processing and welding of small and micro parts.

The working principle of the laser deposition welding system is the welding technology with high thermal energy and centralized spot, which can effectively deal with the welding and repairing of all tiny parts, and make up for the deficiency of traditional argon arc welding technology in repairing and welding fine surface.

The two thresholds of thermal strain and post-treatment are avoided, which greatly saves the production cycle of the mold.

Laser spot welder is mainly used for hole filling and spot welding of gold and silver ornaments, and can also be used for cold welding of high alloy steel, hot forging high alloy steel, nickel tool steel, high grade steel, copper alloy, beryllium copper, high toughness aluminum alloy, gold, silver and other metal materials.

SUNTOP Jewelry spot laser welding machine the main features

The whole machine can be placed desktop, built-in water-cooling design, small space.

Energy, pulse width, frequency, spot size can be adjusted in a large range, to achieve a variety of welding effects.

The parameters are adjusted by the control rod in the closed cavity, which is simple and efficient.

The use of Britain's imported ceramic condensing cavity, corrosion resistance, high temperature resistance, high photoelectric conversion efficiency, condensing cavity life (8-10 years), xenon lamp life more than 8 million times.

The matching hood, eliminate the stimulation to the eyes in the working time.

With 24 hours continuous working ability, the whole machine performance is stable.

Humanized design, ergonomic, long working hours without fatigue.

Main advantages: fast speed, high efficiency, large depth, small deformation, small heat affected area, high welding quality, no pollution, high efficiency and environmental protection.