Details Product Parameters Samples Video

Whether you are an individual user or a business, laser cutting technology provides you with an efficient and accurate processing solution.

1. Specialized Technology

The first thing to consider when choosing a laser cutting service near you is the level of expertise of the service provider. Make sure they have advanced laser cutting equipment and an experienced team of technicians to ensure that your project will be completed with high quality.

2. Fast delivery

Delivery time is also an important consideration when choosing a laser cutting service. Finding a service provider near you can shorten the delivery time so that your project can be realized more quickly.

3. Customized services

Different projects may have different needs, making customized services especially important. Finding a laser cutting service provider that offers personalized and customized services can better meet your needs.

4. Quality Assurance

Whether it is simple cutting or complex engraving, quality is crucial. Choosing a reputable laser cutting service provider will provide you with a quality assurance and give you peace of mind when using their services.

5. Cost-effectiveness

Aside from quality, price is also one of the considerations in choosing a laser cutting service. Finding a service provider near you can save on transportation costs and also be more competitive on price.

6. Customer testimonials

Before choosing a laser cutting service provider, it is good to check their customer reviews. Through the reviews of other customers, you can get a better understanding of the actual performance of the service provider, which will help you make a more informed choice.

Details of laser cutter service near me

1. Fully enclosed design, green glass cover window can filter the laser beam, with laser protection function, in line with European standards.

2. Adopting the famous Swiss brand Raytools laser cutting head, equipped with dynamic auto focus system, which can keep the same distance between the metal sheet and the laser head to achieve accurate cutting effect.

3. Adopts imported servo motor and precision guide rail to ensure high cutting precision, good stability and longer life.

4. With red light indication and pre-running function to ensure the fiber laser cutting machine can find the accurate cutting position.

5. With automatic oil filling function, each magnetic stripe has an oil pipe, press the oil filling switch to automatically lubricate, oil filling once every two months.

6. Specialized software can design or process graphics or text in real time. Flexible and easy to operate.

Advantages of laser cutter service near me

● Precision cutting

Laser cutting machines are capable of high-precision cutting, whether it is metal, plastic or wood. By accurately controlling the position and intensity of the laser beam, we can cut a variety of complex shapes to meet the individual needs of our customers.

● Efficient production

Compared with traditional cutting methods, laser cutting machines have higher production efficiency. The fast and precise cutting process can greatly save time and cost, improve productivity and make your project more efficient and smooth.

● Environmentally friendly and energy saving

Laser cutting machines use optical principles to cut without direct contact with the material, reducing pollution and waste generation. At the same time, laser cutting machines consume less energy, making them an environmentally friendly and energy-saving way of cutting.

● Customized services

We provide customized laser cutting services, personalized according to customers' needs. Whether it is mass production or small batch customization, we can provide cutting solutions to meet your needs.

● Professional team

We have an experienced team of professionals who are skilled in laser cutting technology and are able to provide high quality cutting services to our customers. We pay attention to details to ensure that each product meets customers' requirements.

Application materials of laser cutter service near me

Suitable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminium zinc plate, pickled plate, copper, silver, gold, titanium and other metal materials.

Application industry of laser cutter service near me

Widely used in high precision apparatuses, aluminum copper clad laminates, machinery, electrical apparatuses, metal crate and cabinet, electric appliance shell, metal plate processing, sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

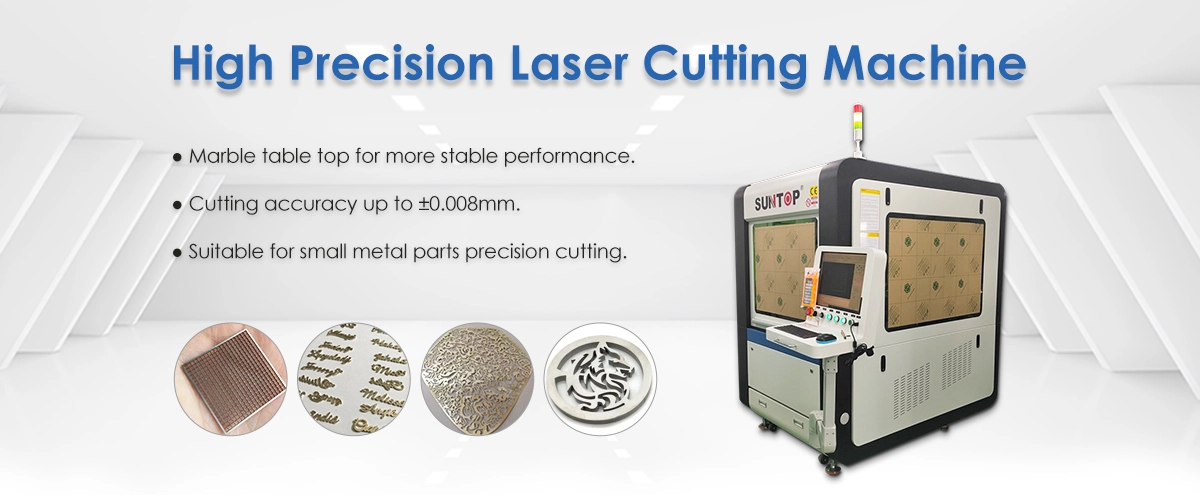

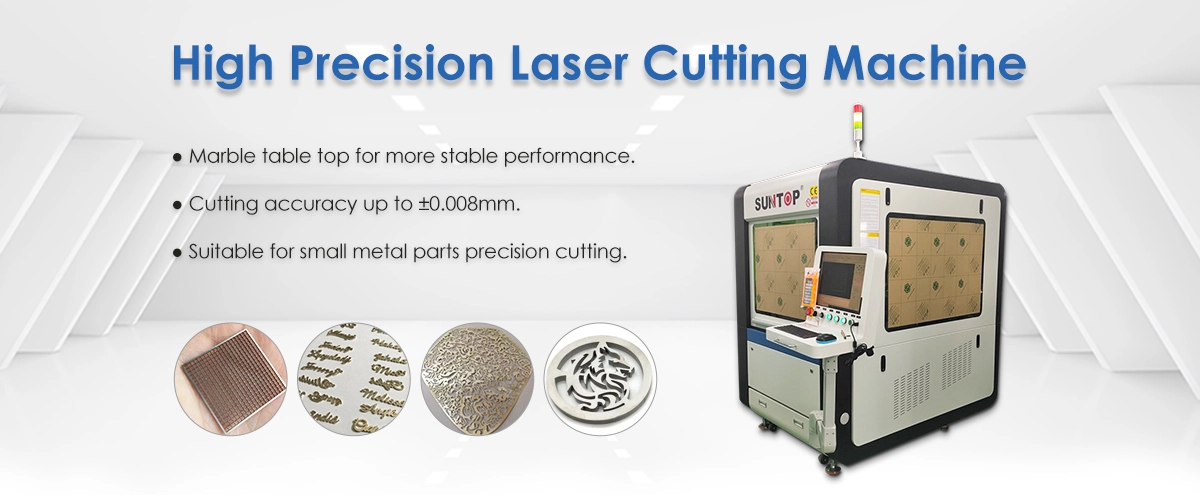

Parameters of laser cutter service near me

Model | ST-FC6060/ST-FC1390/ST-FC2010 |

Table Max. cutting size | 600*600/1300*900mm/2000*1000mm |

Laser power | 1000W/1500W/2000W/3000W/4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choose) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1650*1360*1880mm (depending on actual model) |